Oral-History:John Saby

About John Saby

Saby received his PhD in Physics in 1947 and went to work at the GE Electronics lab soon thereafter. There he worked on semiconductors and transistors, and was involved in the effort to make a commercially manufacturable transistor. In 1956 he transferred to the Lamp Research Lab, and worked there until his retirement in 1982, in research and administrative positions. He worked on electron emission, light-emitting diodes, and phosphor writing/florescent lamps.

About the Interview

JOHN SABY: An Interview Conducted by David Morton, IEEE History Center, 4 April 2000

Interview # 391 for the IEEE History Center, The Institute of Electrical and Electronics Engineering, Inc.

Copyright Statement

This manuscript is being made available for research purposes only. All literary rights in the manuscript, including the right to publish, are reserved to the IEEE History Center. No part of the manuscript may be quoted for publication without the written permission of the Director of IEEE History Center.

Request for permission to quote for publication should be addressed to the IEEE History Center Oral History Program, IEEE History Center, 445 Hoes Lane, Piscataway, NJ 08854 USA or ieee-history@ieee.org. It should include identification of the specific passages to be quoted, anticipated use of the passages, and identification of the user.

It is recommended that this oral history be cited as follows:

John Saby, an oral history conducted in 2000 by David Morton, IEEE History Center, Piscataway, NJ, USA.

Interview

Interview: John Saby

Interviewer: David Morton

Date: 10 April 2000

Place: Hendersonville, NC

Educational background, early employment

Family and education

Morton:

It says here that you were born in Ithaca in March of 1921. Why don’t we start with how you got into the engineering field. Tell me a little bit about your early education.

Saby:

- Audio File

- MP3 Audio

(391 - saby - clip 1.mp3)

I’m a Life Fellow of IEEE, however, I’m classified as a physicist. I tell people it’s like an engineer, only worse. So I was looking for a job. I was a faculty instructor at Cornell. I got my degree in 1947. There weren’t many post-docs then. So I went to get a teaching job at a big university. My parents had both been on at Cornell faculty, I knew Cornell has a good physics department. I got there, but I decided I wasn’t going to get ahead at the university campus under the people as Hans Bethe and Richard Feynman, both then on the faculty. It was a little top heavy, and besides, I didn’t have any other Cornell connections, so I was looking around.

I decided earlier I wanted an academic job, but Lloyd Devore, who had gotten his degrees at Penn State, was the manager of GE Electronics lab, which was fairly new at Syracuse. He wanted an x-ray crystallographer and my Penn State M.S. advisor, W.P. Davey, suggested my name. I didn’t consider myself a crystallographer since my Ph.D. thesis was in wave mechanics and theoretical physics, but I could not pass up an opportunity to see GE. I sent in my resume, which said, “Well, this is what I have done,” and they wrote back saying this is even more interesting. So they had me come over.

Summer employment at Federal Telegraph

Saby:

I had decided not to get into an academic career when I was working a summer job during my junior and senior years at Gettysburg College in the Federal Telegraph, one of the oldest radio equipment manufactures. They owned Mackey Radio (communications), and also Brandes Headphones and other old brands. There was a project engineer in charge of me. Later on when I was chairman of the IRE Convention Record Committee, they had people from each professional group, he was one of the PG members on the Convention Record Committee, an interesting encounter. I saw his obituary in the IEEE publications a few years ago. Well, that was a very hot and grimy place. It was summertime. Instead of having air conditioning, they had salt tablets and lots of water. I said this is pretty grimy; I don’t want that.

Job offer at GE

Saby:

I was raised on vacuum tubes. I always had an experimental attitude towards things, even though my thesis was theoretical. But when I went over to visit the electronics lab, they showed me some conductor work, which is why they needed a crystallographer. The rectifiers I saw were unbelievable. In those days a large number of Type 80 vacuum tube would give you all of hundred milliamperes of rectified current. It had some other inconveniences too, although it was very reliable. Well they showed me a rectifier whose active area of germanium was one square centimeter, which they could rectify 100 amperes. That really impressed me. At the end of the day, somebody asked me what I thought, and they verbally expressed formal intention of making me an offer. We even discussed salary.

When I got home, I came down with polio. In 1951 there was a polio epidemic in Syracuse and I probably got exposed there. They wrote me to offer me formally, and I wrote back and said, “I’d like to accept, but I’m in the hospital with polio. They told me I’m going to walk again because it’s a light case. But I wanted you to know that.” They wrote back a very fine letter which I kept with some other technical and professional souvenirs (which disappeared in a burglary we had in the last few months in a mini storage), saying, “We’re not hiring you to be a long distance runner, but we understand that the muscle between the ears isn’t affected by polio, and we want you anyhow.” They stood by me. The plant physician at GE wanted me to sign a waiver in all the GE medical benefits.

Vacuum tubes, radio hobby

Morton:

Can we back track a little bit? You mentioned something about having a background of vacuum tubes before you came here. Was this from your early days?

Saby:

When I was a kid I made radios—the old regenerative receivers. I even used (I can’t remember the name of it) a very nice name of the instrument. My graduate school roommate, who was a physicist major, and I had some small plug in radio and we wanted to listen to WQXR in New York. You could get it (marginally) in the state college. It’s a fringe area. So I tweaked it up using a panadapter from a Penn State lab to improve reception near the upper end of the scale, which is what you want from WQXR, which is up near the upper end. That was a small example. We had a course in DC precision measurements in graduate school, and also in AC measurements.

Measurements experience at Federal Telegraph

Saby:

That summer I spent as an undergraduate at the Federal Telegraph Company to minimize losses. For cables, we used some surviving lengths of some of the very earliest Litz wires. We were also in the very first lift wireless. We uncoiled some of those muddy yellow-green looking telephone cords we used to have and we put that around a fiber core. All sorts of crude things there. I learned a lot of useful instrumental lore that summer, including use of RF bridge and use of a Q meter, etc.

Morton:

Which branch of Federal Telegraph was this?

Saby:

I think this was at the home office in Newark, New Jersey. I stayed at the Old Halsey Street YMCA. My room was about eight by ten feet, a little dresser and a desk and no air conditioning. It had a single window at one end that overlooked the street, four stories down below where there was a fire station that seemed to answer calls all night. The building was lit by DC, because it was an ancient building with an elevator in it, and the old elevators required DC. They eventually put in their own blower. Ultimately they learned they couldn’t re-wire it because they couldn’t get grandfathered for all that old wiring in the building. So they installed their own DC generator. They hung on to that at least through the summer of 1941, probably through World War II.

My job there was to learn how to make the electrical measurements necessary to carry out the tests required for radio range receivers. The radio range is dot and dash system for aircraft navigation. Serial number one went to Wake Island in 1941; serial number two went to Midway Island. I never did find out whether theirs had ever been installed, because they were manufactured in June and Pearl Harbor came within 6 months. The rest of the radio range receivers in this control were all in the Aleutians—there’s a whole flock of them out there. I did ordinary tests and type tests. The antenna tuning units which I tested had tuning coils wound with Litz wire with a moveable coil inside for tuning. The Q had to be around four hundred. The frequency didn’t help because it was only around sixty kilohertz. They were so sensitive to the losses that if ever one strand was broken in a litz wire, it wouldn’t pass the test. They tried to re-solder it, but it often had to be rewound. I worked with my one project engineer, as well as a federal inspector who oversaw the tests and argued with me about the way I used the slide rule to convert the results. I saw his obituary a few years ago in the IEEE magazine.

I learned an awful lot that summer in a practical way. You see why I was impressed with the semiconductor rectifier with a hundred amperes per square centimeter. Grant you, the germanium rectifier was water cooled. But anything that could rectify a hundred amperes in the fall of 1950 impressed me. With selenium rectifiers, you had to really build a large box full of them to get 100 amperes.

GE Electronics Laboratory Employment

Alloy diffusion transistor

Saby:

When I signed on at the GE Electronics Laboratory, my first assignment (and I was really glad for that) was to see if we could make some sort of a control device using GE’s new way of making junctions, called the alloy junction. We called it the alloy diffusion. That first assignment is why I transistor field so early. That was the fall of 1950.

Shockley had written Holes in Electrons and Semiconductors in 1948 or 1949, but I’d been working at GE for sometime before I ever read the book. That disclosed the idea of a junction transistor as opposed to a “point contact” transistor. GE was already in the point contact diode business and the point contact transistor business. Point contact diode because it could be used as a very high frequency detector. GE’s point contact transistor business came as a follow-on because it was the same sort of manufacturing.

Because of the use of the diodes, they went into the military equipment area. Because they sought quartz crystals to make crystal frequency to control things, naturally you sought crystals to do something with germanium, so they went into the crystal section. That’s how it got into that department, which changed names, of course, like everything else at GE a number of times.

I joined the company then after roughly three months of rehabilitation from polio on February 19, 1951. That was the date I was accepted; I didn’t actually come to work till some weeks later, but they later decided to pay me salary retroactive to when I signed on, so that was very nice of them. They seemed relatively happy about what I was doing.

The point contact semiconductor had an emitter and a collector near each other on top of a plane, essentially. I realized that we wanted to have a better base contact, but we also wanted the emitters closer to the collectors as possible, and the way to do that I thought was to across the thickness of something. That’s really where the alloy transistor idea came from.

The geometry having the emitter and the collector close together and the base sort of around the edges has been used in all the integrated circuits and everything else. You don’t even think of doing it the other way anymore. Well, there are some cases where the emitter and the collector are side by side because of particular reasons, but for any amount of current at all, you have to do that.

Morton:

Now, was that a patentable idea?

Saby:

- Audio File

- MP3 Audio

(391 - saby - clip 2.mp3)

Well yes. Actually we didn’t apply for it till more than a year later. We informally disclosed the alloy diffusion transistor at the same time as Bell. There was a limited attendance semiconductor conference in June. Well actually, it was electronic devices that prior to this concerned primarily tubes. It was an annual conference. It was supposedly an off-the-record conference. You couldn’t use it as a reference in literature. That way people felt they could be a little bit more frank than they would be otherwise. Legally, you were still publishing it because the patent people say if you tell it to anybody it is published. But my PNP germanium alloy diffusion transistor was disclosed at the same session where Bell disclosed (outside Bell) their grown junction transistor with the wires sticking out to the side. My paper was the paper before Bell’s, so we’d been through that. That was partly because Bell didn’t care where theirs was because they didn’t have a clue what we had been doing. Also, because Crawford Dunlap, one of the co-inventors of this junction process, happened to be technical program chairman.

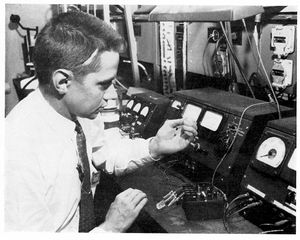

Anyway, I got assigned that work on the new transistor. It turned out you could get reasonable power amplification. They built a number of gadgets using the new laboratory-made transistor. As shown in those pictures of Dick Shay talking into a transistor operating a microphone. He also made his own hearing aid about the size of about two packs of cigarettes, that fit in his pocket. It was very much admired by Dr. Coolidge at the research lab when we visited there because he used a hearing aid, and they were still using miniature tubes.

Lloyd Devore apparently said something to W.R.G. Baker, V.P. and general manager of the electronics division about it. This was on Friday and Baker said he’d like to see me Monday morning. So I came in on Saturday and made about a dozen transistors just to give him an idea how fast you could make them. I did it by hand; we had no jigs at that time. They weren’t very good, but at least it demonstrated how long it took to run through the process.

IRE committee work

Saby:

This gets me to IRE. I hadn’t joined IRE, yet. I’m a physicist, not an engineer, really. The two cross over, it’s true, but I at that point hadn’t appreciated how much activity would involve engineering rather than physics. In those days it involved a lot of both.

“Committee Seven” was about to be split. But before they split (I suspected at Doc Baker’s suggestion), they asked me if I’d serve on the committee, and I ended up for a month or two being the secretary of Committee Seven, even though Committee Seven was about to disappear, and they broke things up before I even ever attended a meeting. They formed a guiding group for electronic devices. Officially those were standards committees. Later on, the concept of professional groups was a lot broader than standards. Somewhere along the line people realized that, “Hey, you can’t do that unless you belong.” So they told me I’d better join the IRE. quick, so I did. No trouble getting in of course.

I was on an administrative committee from 1952 when it got formed until 1956 when I moved out to Cleveland. In fact, that fall the last thing I did with them was preside over part of a luncheon meeting they had during the fall, I guess devices meetings. It used to be in the tube conference, and it became electron devices, and I suppose there are two now, but I don’t even know.

Morton:

When you joined, you almost immediately went into some of the committee works, so you must have already known some people.

Saby:

Well, Doc Baker knew some people.

Transistor developments

Scholarly reception, patents, manufacturing

Saby:

Actually, I know that Shockley was very impressed because this took him completely by surprise. I know that because I was at Cornell as an instructor and Shockley was invited there to give a talk, and he knew me from all that stuff, and he mentioned something about my work. He said this is a very, very producible structure, which is true. Because the grown junction thing with the whisker located in just the right places wasn’t producible at all. They sold a few, but it wasn’t producible at all. The research lab patent people felt themselves that they had covered all reasonable patent ground with the original disclosure of the PN junction, the alloy diffusion junction. In fact, Bob Hall had even made some power transistors by putting lines back and forth beside each other—base emitter, base emitter. I think that shows in his patent. But nobody had showed emitter base on top and collector down below, or vice versa. That’s also where you want to put a heat sink. It works out very well. So a corporate R&D patent attorney told our patent attorneys that with the junction formation convex there’s nothing left to patent. Thus, we didn’t end up patenting anything until June 1952. After we filed, we learned that RCA had filed their application one day earlier that we, so they were the senior party and we were the junior party in the subsequent patent interference, so we had the burden of proof priority.

They visited us. Russ Law, who was in charge of the RCA color tube group then, and Jacques Pankove (formerly Panchetnikov).

Morton:

I thought Law was with RCA?

Saby:

At that time he was. They put him in charge of a new transistor group. They reorganized things. I didn’t know any of this first hand; it’s all from second and third hand. Essentially they stripped a lot of talent out of the tube group and put guys together who were big achievers, and then they paid a visit to us up in Cleveland. They’d seen the process and they came up with improvement on the way you carry out the process. They provided necessary heat to form the junctions by passing the parts through a continuously heated tunnel oven, all before we ever applied. Finally we did apply, we’re the junior party, RCA never wasted a minute trying to put in patent applications. In fact, we’d see their patent dockets for new transistor circuits (something you got by being in their patent pool), and they took just about every combination of a resistor and a transistor, or two resistors and two transistors. You could just almost make a table of what they did. Every month we’d get a thick stack just of one sheet disclosures. I don’t know how many of them had been tried out.

Finally, we went to the patent examiner. There was an interference, for nine years, we kept back and forth on it. By that time I think the first silicon of transistors had come out; and at that point, days were numbered. Although there were millions of these alloy transistors made. I don’t know of a single commercially quantity transistor produced in that era that wasn’t produced under our patent. That was one reason why it was important to get it granted because otherwise there would be a lot of retroactive patent royalty claims.

It is interesting to note that all germanium transistors had been made obsolete (by silicon’s higher temperature characteristics) before our patent finally issued

Publications; IRE professional group on electric devices

Saby:

That was a very interesting time. Cal Sheckler (A. C. Sheckler), who very briefly was chairman of the PGED. That might have been after he left GE and went to Carrier. He was also in our group in Syracuse. Vern Oyaron also was a member of our group, initially under Paul Jordan. The group started out sort of feeling its way. In the first month we had only a very limited understanding of the operation of our junction transistor. Fairly early, it was suggested that the IRE-PGED, i.e., the professional group on electric devices (non-vacuum tube devices), should initiate a technical publication. We sent some invitations for papers out in the first issue of Transactions. I was chairman of the publications committee at that point. We hadn’t formally named an editor yet, but since it came out then I was by de facto the first editor (and not a very good editor, at that) of the PGED Transactions. A very able scientist at Bell Lab sent us a very good paper that we published. Then he commented, “You know, you’re publishing this thing that’s mimeographed. You ought to get into letter press publication.” We did switch to letter press within the year.

I started out being secretary of the IRE-PGED (which was a hang over from the Committee Seven), and then ultimately became the chairman of the group. I know I became chairman about ’54 or ’55—’55. Richard F. Shay edited a new book Principles & Transistor Circuits. Published in 1953, it was still in print twenty years later in 1973. They invited all of the authors back for a celebratory luncheon, but they were at that point going to let it go out of print because after twenty years it was out of date. But it got a tremendous head start. It was the first university-level transistor textbook. It was translated to about seven languages. There was even a pirated translation published in Russia. Every time a new country would sign an agreement with them, we’d get a couple of cents of royalty instead of a couple of dollars. GE allowed the authors to keep all the royalties. The publisher, John Wiley, was after other publications

Morton:

I was going to ask about that. So I guess they were pretty supportive. I’ve heard that sometimes other companies…

Saby:

Oh they were. They supported another thing, that really paid off for GE. I mentioned the University of Illinois. Well, there are nine co-authors to that book. There were seven different passports, and of the different passports, most of them still didn’t have American citizenship. They were in electronics laboratory where their work is virtually all government supported and therefore classified and security clearance was a given. Lloyd Devore, who hired me, talked to the GE brass into going along with hiring a lot of these unclearable people—unclearable at that time. It included Jerry Suran from Armenia; he was the president of the IEEE for a while. Ed Keonjian, who was White Russian. Dick Shay, of course, and Warren Mathis, both of whom were American. Woo Foung Chow, who was Chinese, but not from Red China. Sorab Ghandi from India; Johannes Schaffner from Switzerland; and Charles Rosen of Canada. And myself, of course. That’s real interesting line up of co-authors. We had to do the proofreading actual production part of it in our own time. GE said we shouldn’t obviously be spending a lot of time, but they didn’t ban it from being discussed and having meetings about it. I remember we proofread it at Dick Shay’s house when we started to read it in print. That was a fun time.

GE work environment

Relationships between research and development

Morton:

I haven’t spoken to too many people about their experiences doing research at GE, but I’ve spoken to more people about their experiences at Bell Labs. At Bell Labs there was a real rivalry between research side and the development side.

Saby:

I think that’s everywhere. I mentioned that the research lab felt that there wasn’t anything patentable because they had done it and they knew that they had covered the ground. There’s what some of us call the fount of all wisdom syndrome, you get with the central research lab. Not that they consciously feel that way. They feel that way so deeply they feel it unconsciously, which makes it difficult. In the electronics lab I was always in the middle. I had to communicate and do useful work with the research lab people, and we respected each other. With the people in the factory and the people in the engineering section, there was some rivalry between the electronics lab and the engineering sections of the product departments. Because we were supported by assessment rather than by project. Although we did get projects to cover our assessment, the amount of budget we were going to paid was certain foreordained. It was just a question of having to negotiate the projects that would add up to that.

Electronics laboratory

Morton:

Technically speaking, were you on the research side or were you on the development side?

Saby:

I was in the electronics laboratory.

Morton:

Which was something else completely?

Saby:

It was a division laboratory and our function was in between research and development. What we had called a division they now call a group or a strategic business group. With many of the people in the research lab particularly, the higher you go in the hierarchy there, the more they called everybody else in the company peons. But at the working level of research groups there and our research people, they could get back and forth fine. We had a certain amount of freedom to pursue our own ideas. Doc Baker had good vision that way. That disappeared later because of changes in management. That was a time in history when it paid to be flexible. I’m not sure it does now; maybe it does. In early transistor times it did play to be flexible. But it does always make sense to ask questions of Mother Nature, whose answers were useful. Someone defined pure research as you don’t know quite what you’re doing and you don’t know why you’re doing it. Engineering is you know what you’re doing and you know why you’re doing it. Applied research is somewhere in the middle: you’re still doing research, you know why you’re doing it, but you may not fully understand what you’re doing. You are finding facts of nature, but you know why you’re doing it. You’re working in that field because you have some faith that the results in that field will be useful to a particular area of the company. Research labs claims not to have that restriction if they’re talking to research colleagues in universities, but if you’re talking to people in departments, of course, they claim to have it very religiously.

Morton:

Of course.

Saby:

That’s a part of the politics of getting support for technical work. That’s just the way the world is.

Collaboration and secrecy

Morton:

Another thing I’ve heard about Bell Labs is that they often had two different groups working on essentially the same kind of problem without talking to each other.

Saby:

I’m not as familiar with that at all. It’s entirely possible, but I can’t think of any examples. I know the semiconductor people. I knew Jack Morton and I knew Pankov with RCA, who was the theorist they had there who went out to work with Shockley.

Morton:

Was the person you’re thinking of one of the three Nobel sharers?

Saby:

I also was well acquainted with William Shockley. Credit is very important. To be sure, it is your stock and trade. The more credit you get for things, the more credibility you have when you’re asking for something. I can’t say it’s entirely reasonable.

Patents and liability

Saby:

Also, the patent people get in there too. For a long time when we first started, we didn’t say we had made a transistor because the Bell Labs people invented the transistor, and the legal people in GE felt that if we used the word transistor we would be automatically assuming liability under some patents that we wouldn’t otherwise be assuming liability under. Also, for a long time the Bell patent people were very ungenerous about acknowledging any work by others in the same field. In crystal growing, for example, Gordon Teal wrote papers on crystal growing, but never disclosed a lot of the details of the process to get the crystals to grow. People who grew crystals generally had to discover themselves, and people in academia were teed off by this because Bell would print all these things, but they didn’t really tell you how to make crystals that you could perform independent research on, unless you got down on your knees and ask them for a piece of crystal.

Meeting Ronald Reagan

Saby:

Incidentally, I have a picture of me and Ronald Reagan when he was making the circuit. I was showing him the germanium crystal at the laboratory there.

Morton:

When was this? Was this back in his governor days or this is later?

Saby:

No, it was before he got into politics really. He’d been a sportscaster, and he always talked off the cuff. He came to do commercials. He did voice commercials for GE. He never worked from scripts. In sports he understood the situation—he talked from his knowledge. Well, he did that with everything he did, so when they wanted him to cover different parts of the company, he had to pay a visit to all involved areas at GE, to get an idea about what they were doing. Then they’d go over the points that they needed to have covered so then he could talk from them. It’s the way he operated. So he was in Syracuse to cover electronics. He visited a number of areas at Electronics Park. Of course the publicity people were taking pictures right and left because he was pretty well known, since he was a big movie star. After the visit they’d pick out a few pictures that they might use some time and send a lot of the people who’d been in the pictures 8 x 10 glosses of that particular encounter, and then you’d have a good personal souvenir. When I retired our lighting laboratory sent a print of it to the White House and got Reagan’s signature on it (the signature was probably done by machine like they do the routine ones.) However, I do have the wrapping that it came back in, and it was Federal Express and the return address was the White House, Washington DC. That’s good enough for me. I keep that as a bit of extra documentation. Fortunately I didn’t have that stuff in miscellaneous boxes that looked interesting to the thieves who looted our storage garage last December.

GE Lamp Research Lab

Research, light emitting diodes development

Morton:

Following this, it looks like in ’56 you went to the Lamp Research Lab. That sounds like an interesting change of pace.

Saby:

- Audio File

- MP3 Audio

(391 - saby - clip 3.mp3)

It was, actually. I’m a physicist primarily, and it was turning into a technology by 1956. I had a good offer to go out with Gordon Teal in Texas. The position was to be manager of engineering. I don’t consider myself an engineer in the administrative sense of the word. But anyway, in Cleveland they made me a very interesting offer of what was then called the Lamp Research Lab, which involved research in a lot of different fields. I’d get more variety in research topics. Same idea I was talking about earlier. I kept that position for the rest of my GE career. Managers changed at the top, and as budgets got pinched more and more, that disappeared more and more. As a matter of fact, thanks to Neutron Jack (you know who I mean) the building is there, but I don’t know if there’s anybody in it anymore. However, for some fifteen or more years it was a good way to work.

Many types of research are needed for lamps, for example, electron emission. You’d worry about residual gases messing up the cathode of a tube. A florescent lamp cathode operates not in a vacuum, but in a low pressure of a rare gas. Mercury vapor is also present. There are heavy mercury ions flying around, yet you require the cathode to function up to last ten, twenty thousand hours. There are some things that had to be learned about that.

Also for a while we were concerned with what was called then light emitting diodes, and the GE miniature lamp people actually had a product development. We made some silicon carbide junctions—we used crystals of silicon carbide and formal junctions in them. They would emit a yellowish-green light instead of a red light that most of the junctions did. We worked on that a lot longer than I think we should have.

There were all sorts of things that really involve basic physics that aren’t understood. Langmuir and Coolidge at the corporate research lab were not above working with incandescent lamp filaments. Their main contribution was to figure out how to make them so they wouldn’t sag when the lamp is operated. The purpose was as down to Earth as you like, but the science behind is good and basic—and it was successful.

Fluorescent lamp phosphors

Saby:

The function of lamp phosphors was another we were working in. The earliest good fluorescent lamp phosphors was zinc beryllium silicate. That’s fine except it’s made with beryllium oxide, and they discovered later on that beryllium oxide is an extreme poison to some people but not all people. Brush Beryllium Corporation was in Cleveland. They fought lawsuits. They said, “We were as safe as we knew how to be but we didn’t know enough. Too bad.” They didn’t lose any lawsuits. Now in today’s climate they probably would lose lawsuits. GE went the other way and they told people, “Look, all of you in this building have been exposed.” Even a typist clear on the other end of the building came down with berylliosis. It essentially gives you super arthritis-like symptoms in your joints, among other bad features. At the other extreme a man in the factory where they’re actually firing the stuff, mixing shovels full of the stuff, and it’s in the air. He didn’t get poisoned at all. “Some of you have been exposed, some of you already had symptoms. What we’d like you to do is submit to an annual physical exam. If there are any symptoms at all, we’ll give you the very best preventative medicine known at that time to try to keep the symptoms from getting any worse.” There’s no hope from removing it from the body. They said, “We’re going to work with you. But just keep letting us check on you.” That was really good faith. Some of them were to have an uncomfortable rest of their lives, but they knew at least GE was going to do everything possibly good without any further obligation to do it. Top management did the right thing for the right reason. The GE medical administrator earned some real recognition because he kept that from ever being an issue just by having GE be as good as they possibly could to people. At a lot of places at GE people would do that. They were very good to me, although I didn’t really require any special treatment. Just trusting me (re my minor disability) was good enough. I only ever missed one day because of illness (due to the flu), and I only ever missed one-half day on account of an accident when I fell and had a compression fracture in my back. That was my only disability that was even remotely related to polio. So a lot of people in GE were trying to do the right thing. As a stockholder I’m grateful to Jack Welch for making the company so profitable, but it’s not the same company to work for that it used to be.

Morton:

Regarding phosphor, what kinds of phosphor research are needed for lamps?

Saby:

An example: Fluorescent lamps use a low-pressure mercury electrical discharge—a mercury discharge in an inert gas at low-rate pressure. This kind of discharge emits a large proportion of the imput energy at one ultraviolet wave length, which is a very efficient exciter of the phosphors, which in turn makes visible light in a fluorescent lamp. There isn’t any other gas discharge situation where we know the efficiency to be so light. That’s a tremendous percentage. The discharge produces ultraviolet, which is invisible. So you’ve got to turn it into a visible light. In a fluorescent lamp, you shine the ultraviolet light on a layer of phosphor powder in the inside of the tube and it turns it into the fluorescent lamp. So phosphors are very important. If you’ve heard people say, “I won’t have a florescent lamp in my house,” that’s because all they’ve seen is the standard cool white, which makes more usable light per total watt than anything else, but it’s deficient in the deep red and in the deep blue and white. The appearance is right, but if you came in with a red neck tie in the morning and standard F-lamps illuminate your bathroom mirror, it’s going to look like it’s maroon. That’s no good.

In parking lots, high-pressure mercury light lamps makes a lot more light that they used to, and it is better light. Now they used to be bare, now they put phosphorus in the inside of the outer jacket because the arc tube produces a lot of UV and the UV can be turned into visible. That can also be done by developing phosphors with a particular color output to fill in the parts of the visible spectrum that the mercury doesn’t produce. So you can get pretty decent color. You notice the difference with light from the old bleak, bluish-looking mercury lamps, when you look for your car in the parking lot you can’t find it unless you know the license plate because the color looks wrong. But with better phosphors you can make better light.

In buying florescent lamps for your house or workshop where color matching is important, various brands have deluxe color lamps which provide good color rendition. But you have to go to places knowledgeable enough so they know, and a place that stocks them. The corner hardware stores don’t want to stock more than one kind of anything. They all sell cool white because that’s cheap, and it does make a lot of light.

Management philosophy

Morton:

Well, you don’t have anything listed after that, so you tell me. You stop when you go to Cleveland.

Saby:

I’ve been talking about what I was doing in Cleveland. I figured my job was to have people in the group who had more ideas than I do. I wasn’t the kind of manager who figured, “These are my ideas, and I’ll get a real good staff to carry them out.” My job was to identify people with good ideas and push them.

I retired from GE then in 1982. From ’56 to ’82, nearly twenty-five years, I was out there in Cleveland.

Morton:

Did you prefer the management side of the, your career or the engineering side?

Saby:

No. I liked the technical side, which was more physics than it was engineering. But if it’s applied research, you can’t ignore what the engineers are going to have to be able to do with it. In my whole career, I’ve always been in the middle between the pure scientist up here and the guy who only wants the answer down there. We talked about the two cultures. Believe me, it’s that way there, and I had foot in both camps. It stretches you sometimes, but that’s the way I enjoyed working. I ran into that same philosophical tension in Cleveland as I did in Syracuse.

So, I enjoyed more the interactions, the technical part of managing. Now the administrative parts—figuring out the totem poles and if we got a cut back how did you decide whom to lay off, etc.—a manager has full responsibility for some of those things—just part of the administrator’s job. But I did enjoy sitting down with people and understanding what they’re doing and asking questions. I’ve had a fair amount of acknowledgment from people that apparently felt I was useful to them. I certainly enjoyed my fortune to have worked with a lot of very good people during my career.

Business competition

GE, 1970s-1980s

Morton:

Now was this part of GE’s business effected in the ’70s or ’80s the way some of the other parts of GE’s business was effected by the overseas competitors or things like that? Was there any major shift in that end of the business?

Saby:

There’s a lighting group here in Hendersonville. That division really makes the light systems. They’re the people who make the poles and the controllers and design the lighting systems for say a whole parking area or a whole building or a whole traffic situation for a city. The problem there is GE has very high overhead, as you know, and many our competitors stay in business by producing products as cheaply as possible. We call them tin benders. Things get made cheaply. When you buy a ballast for a florescent lamp, it pays to buy a certified ballast, but you’ve got to pay more for it. The lamp will burn 40 watts if it’s a 40 watts florescent, but if it isn’t a certified ballast, you can’t guarantee it will put out as much light as it ought to. There’s some other things about it that you can’t do well. Municipalities in particular who are required in many cases to go to the lowest bidder, even though the salesman for GE can say, “Well look, you’re going to have to replace that thing within ten years.” “That’s alright. We get the money for this now. We can’t get as much money as we need to do it right, so we’ll do it cheap.” If the city manager people are good they realize what they’re doing, but they have no choice, and this is the problem. Just like a tremendous fraction of our bridges are going bad because a city engineer can’t elected promising to fix the bridges before they’ve fallen down.

Morton:

So with, lower price products coming on the market, were they…

Saby:

It has forced GE out of some business. For example, GE no longer makes florescent ballast because of that.

Morton:

Is that mostly overseas now, or is that just…

Saby:

It can also be cheap domestic productions. It started out to be. Actually nowadays everything can be overseas. For a long time, GE was the last remaining manufacturer to be making any ordinary radios. What GE tends to do, and I think other major companies, is to have a good enough staff to really design what you really need and you get the design to your full specifications. Then you can do it here or you can do it in Hong Kong or you can do it in Singapore or you can do it in India or Brazil—anywhere you want to in the world. I think that’s the way its going. That’s changed the nature. There are still some factories. We’re still making ordinary light bulbs because we saw this coming and decided we would become the low cost producers. You’ve got a certain amount of glass blowing to do.

Glass blowing and manufacturing

Saby:

- Audio File

- MP3 Audio

(391 - saby - clip 4.mp3)

By the way there’s an interesting story in the lighting business. Edison invented the light bulb. But it turns out, nearly all the contributed value of manufacturing that is in the glass blowing. At least it was, when they had to be blown by hand and clamp the wires in and seal it by hand. So people who could blow glass, if they were more skilled, they could make bulbs cheaper than GE could because GE just didn’t have generations of glass blowers. Ohio has a lot of good sand for making glass, and a number of other things that make it possible. There were a number of glass companies in Ohio because it was a good product for Ohio’s natural resources. In the early days, there were a bunch of them making lamps. There was a Packard Lamp Company and a Cambridge Lamp Company, which was a corner of the glass business. As competitors in GE’s Edison Lamp, they realized that nobody had ever heard of them. GE has a well-known name. So they said, “Let’s get together and form an association, and then with this association we can do common advertising, have some common branding, we can do common R & D.” One of the early developments they had was the rotary lamp machine. Did you ever see a pie factory? You do one operation on the lamp-to-be, and then the machine rotates to the next section. They make pies the same way. At Petro Pie Factory in Frankfurt, Michigan, I saw what I’m sure was a converted old incandescent lamp machine being used. They have a tray spinning, you put the crumbs down on it, and the next section whangs it out, and the next section you put something in it and the next section they put something else on, and so on. The idea of rotary machinery was born out in Ohio, not by GE, but by the National Electric Lamp Association (NELA).

They found that this could get to be real big time because they could undersell GE and make equally good lamps and still make a lot of money. They had the necessary skills—they did it faster and better than GE, but the association was small. They said, “Let’s get organized on paper then draw up some bonds and sell the bonds to somebody and get the money to build high factions.” Well nobody wanted to buy the bonds. GE finally bought them, with the idea that within a certain number of years GE would either sell the bonds publicly or they would buy out the company. When the lamp division came into the company, GE decided to keep it. But here were GE people in New Jersey being put out of business by somebody else in the same company. That literally happened. When I joined the company in 1956, there was still old-timers that couldn’t forget the fact that the lamp division decided, “Well sure, you guys can brag all you want to, but in 1932 or ’33 the company made two million dollars total, three million of which was made by us.” That didn’t go over very well.

Morton:

It is an amazing product, though.

Saby:

To assimilate them, and to reduce distrust, GE said, “You can keep on running your company, just give us so much off the top.” That’s unheard of today. So NELA making money hand over fist, and GE was getting a big share of it. Customers were getting a better lamp cheaper than they had before, although not near as cheap as it could have been made. But they kept the GE ownership of NELA secret for a long time, then finally when they bought it out, they did allow it, and then they allowed the use the GE monogram.

National Electric Lamp Association (NELA) Park

Saby:

By the way, Mazda is generally regarded as a Westinghouse Lamp brand. That was an early defense against foreign competition. This brings us back to the foreign competitions question. There were very cheap lamps coming in, not very well made. So the people at NELA Park, at that time National Electric Lamp Association (NELA), which is now by the way on the US historical register as a pioneer park-type industrial site. GE and NELA built NELA Park out in the sticks, about 1911, and they ran a trolley line out in a “first to do this, first to do that” sort of thing. There was a lot of hocus pocus when NELA came into GE. They kept it secret, and they ran things to suit themselves, including a luxury training site on “association island” in Lake Ontario. I don’t know if you’ve ever read Kurt Vonnegut ’s popular novel Player Piano. Player Piano is based on GE’s association island. It’s a real island, which the company took over from the lighting business, but the lighting business had had it since about 1912. The last summer it was used as an executive training cite was 1956, which I attended.

Morton:

Out on the lake?

Saby:

Lake Ontario, a couple of miles out from shore from Pulaski, NY. I had given to the IEEE History Center a bunch of old lamp stuff, including this Camp NELA brochure from 1921.

This souvenir of association island had a deeply embossed cover with some beautiful stuff, beautiful slick half-tone drawings, and then complete scripts for the entertainment play. It was way unbelievable. It was paternalistic for sure, but it was unbelievably. The Mazda trade name came and they were threatened by the cheap imitations, so they said, “Well let’s get a list of specifications. The factory is going to make those specifications and we’ll sell them under the Mazda name.”

When GE, Westinghouse and Western Electric in the 1920s were found to be conspiring in antitrust business, that’s when RCA was formed. Westinghouse kept the Mazda name. Western Electric didn’t make very many lamps after that. GE has maintained that. There are a couple of very small specialized lamps that GE sells to this day with the Mazda name, just keeping alive their ability to use it.

But the foreign competition isn’t new. It happened with watches in the 1890s, and that’s the origin of the law requires items that are imported to bear the name of the country of origin. I have a Southbend watch that was made in Switzerland. It’s a cheap imitation of an American watch, it even looks like an American watch, but the innards weren’t nearly the same. That is always the question with foreign competition—is the product comparable or isn’t it.

- Lasers, lighting & electrooptics

- Computing and electronics

- People and organizations

- Scientists

- Research and development labs

- Corporations

- Solid state circuits

- Transistors

- Electron devices

- Vacuum technology

- Materials

- Metals

- Alloys

- Engineering and society

- Law & government

- Patents

- Fluorescent lighting

- Profession

- Management

- News