Oral-History:Keld Harder

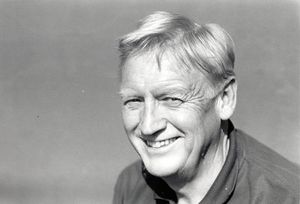

About Keld Harder

Born in Copenhagen in 1933, Keld Harder as a youth worked as a technician and apprentice for a radio dealer. After receiving his degree in electrical engineering, his work at Bang & Olufsen focused first on the engineering of products including the Beolit 500 and Beomaster 900 radios. His later work at B&O focused on marketing radio and television. His background as an engineer benefited him both as a salesman and lobbyist, providing technical credibility and enabling him to identify technological trends. Harder’s oral history focuses primarily on the challenges he faced in marketing, particularly in his dealings with foreign countries.

About the Interview

KELD HARDER: An Interview Conducted by Frederik Nebeker, Center for the History of Electrical Engineering, 23 July 1996

Interview #309 for the Center for the History of Electrical Engineering, The Institute of Electrical and Electronics Engineers, Inc.

Copyright Statement

This manuscript is being made available for research purposes only. All literary rights in the manuscript, including the right to publish, are reserved to the IEEE History Center. No part of the manuscript may be quoted for publication without the written permission of the Director of IEEE History Center.

Request for permission to quote for publication should be addressed to the IEEE History Center Oral History Program, IEEE History Center, 445 Hoes Lane, Piscataway, NJ 08854 USA or ieee-history@ieee.org. It should include identification of the specific passages to be quoted, anticipated use of the passages, and identification of the user.

It is recommended that this oral history be cited as follows:

Keld Harder, an oral history conducted in 1996 by Frederik Nebeker, IEEE History Center, Piscataway, NJ, USA

Interview

INTERVIEW: Keld Harder

INTERVIEWER: Frederik Nebeker

DATE: July 23, 1996

PLACE: Peninsula of Helgenaes, East Jutland, Denmark

Childhood and education

Nebeker:

This is the 23rd of July 1996. I’m talking with Keld Harder. This is Rick Nebeker. Could we start with your telling me where and when you were born and a little bit about your family?

Harder:

I was born in 1933, in Copenhagen. Very early in my life my parents moved to Aarhus, which is just opposite here. I lived there until I was twenty eight years old and then I moved to Struer. When I studied electronic engineering my wife wrote all my reports, and then I felt an obligation to marry her, of course. That has been very successful. We have been married for thirty eight years now. We have two children, both married in Copenhagen. One is an electronic engineer like me and he is doing very well indeed. He is a much better engineer then I am. The other one is a merchant man, selling American computers. He also teaches the computer and he is very good at it. And we have four grandchildren.

Nebeker:

Tell me about your education.

Harder:

After primary school I was an apprentice, as it was called for radio mechanics. So, in the early fifties I drove around in Aarhus on my bicycle and repaired peoples radios.

Nebeker:

So you were working for a radio technician?

Harder:

A radio dealer. I was a technician and an apprentice there for four years. Then I decided I would study to become an electronics engineer. So, I continued after the four years and then studied three years.

Nebeker:

Where was that?

Harder:

That was at Aarhus just opposite here. There was a tradition there actually, that Bang & Olufsen took the best from the annual team and they were always hand-picked. It was very strange because I think I passed at least forty exams and when I was going to be employed at Bang & Olufsen, nobody wanted to see my certificate. That was very disappointing. Actually I didn’t really know whether I was employed or not, so I borrowed my father-in-law's car and went up there and asked if I was employed there. They said “yes, we were expecting you.”

Nebeker:

Had you decided from an early age that you wanted to work with radio?

Harder:

No. I would say it was a coincidence. At that time I saw some future in television and I was very interested in it, but that was far away when I started. Television started in the late fifties in Denmark.

Nebeker:

But the education you took here was in the weak current, communications line and the technical.

Harder:

It was rather broad at that time. We had to do everything. It was more than just engineering. I think we were among the very first, in what was later called electronics. Normally they make high tension wires.

Nebeker:

Power engineering.

Harder:

Yes, and from that was derived another education which was weak current. So I think we were actually breaking the waves there and were doing something new. So we did a lot of things that were absolutely without any practical use. I think that what you learned was systematic and that was the important part of it. I was very lucky because I was on the very first team that learned something about transistors. That became the key to my further work at Bang & Olufsen.

Bang & Olufsen

Transistor radio design; Beolit 500

Nebeker:

What year were you finished and what did you get your degree in?

Harder:

1958. I joined the Bang & Olufsen on the first of November, 1958. And I was actually one of the first engineers employed after a very deep depression the company had. I think that when I arrived there were three hundred employees.

Nebeker:

What was your initial assignment?

Harder:

- Audio File

- MP3 Audio

(309 - harder - clip 1.mp3)

My initial assignment was to design transistors for portable radios. Actually, it was under the supervision of Knud Holst, whom I had just met. So, he was my first boss at Bang & Olufsen. I made quite a few portables and actually those portables were the biggest sellers ever produced at Bang & Olufsen. I produced six hundred per day. That was a tremendous amount at that time.

Nebeker:

That is impressive. I know that Bang & Olufsen was the first out in Denmark with the transistor radio.

Harder:

Yes, they had a very good reputation for it. And that’s what I did in the beginning. Actually I made the electronic design and the mechanical design for the very first product that Bang & Olufsen had at the Museum of Modern Art: the Beolit 500. Of course a very flat one, which I think really expressed what Bang & Olufsen is today, to come at that time because there were only five buttons where you selected programs. They were huge buttons because they were meant for the kitchen, so that you could actually operate it with your elbow.

Nebeker:

Is that right?

Harder:

There were only five knobs, then there was volume and on, off, and that was all and it was beautiful. It’s in the Museum of the Modern Art.

Nebeker:

Is that the one that had a sliding tuner?

Harder:

No.

Nebeker:

That was later.

Harder:

It was approximately the size of a cigar box more or less. On the left hand side there were five buttons and then there was the volume button to the right. And you could place it vertical or horizontal. That became rather popular.

Nebeker:

What was the case made out of?

Harder:

It was wood. At that time it was real genuine wood. You could get it in teak and rose wood and mahogany. It was really a piece of furniture.

Nebeker:

And your part in that was the circuit design?

Harder:

Yes, and I gave the basic idea. I made the basic drawings of the outside of it - the idea and content of it - then it was Benadotte the designer, who polished it and made right proportions, but the basic idea I did.

Nebeker:

I guess that was how Jacob Jensen became known to Bang & Olufsen; he worked for Benadotte for a period.

Harder:

Yes. But he works in a different way. In this period, Beolit 500 was generated by the engineer and then the designer added the cosmetics to it, but the basic idea was developed by the engineer. But Jacob Jensen is working in another way: outside in. He produces a specific exterior. He challenges the engineer to put something electronic in it, and that’s his working method.

Nebeker:

Was this typical of the earlier period, that the products would be suggested by the engineers?

Harder:

Yes.

Nebeker:

They probably didn’t even hire designers in those days.

Harder:

No. I think that was due to Jacob Jensen, who saw that the company was, as all companies were, typically engineer driven at that time, and he saw that it couldn’t last. I think that Jensen really did the great thing to add designers to the company together with some skilled engineers.

Nebeker:

But the company has always operated with external designers, is that right?

Harder:

It’s due to the fact that sooner or later they were running out of inspiration and it’s very hard to get rid of an employee. I think that the challenge to the designer is much bigger if he is a freelancer. Jens Bang always had a few designers connected to the company. He always had a bunch of them warming up, dealing in small assignments to see if there was any potential in them. That worked very well indeed.

Nebeker:

I think it was in '64 that Jacob Jensen began working with Bang & Olufsen. Do you remember when that Beolit 500 was marketed?

Harder:

I can’t remember it exactly.

Nebeker:

Okay. But it was probably in 1960 or something like that?

Harder:

Yes.

Nebeker:

What was your next project?

Transistors and circuit design; mains-driven transistor radio

Harder:

When I worked with transistors, I noticed that output transistors at that time were working under or below forty volts, that means that you get another freedom in your design. That gave the inspiration to the world’s first mains-driven transistor radio, which I generated, and which later on was very successful. Strangely enough, the inspiration came from cars. In the very beginning of the car industry, cars had a chassis frame, where you build the body, and then later on you got rid of the chassis frame and had a self-contained body which was so stiff that you wouldn’t have the wheels or the motor in it. So at that time a normal radio would have a chassis put in through the cabinet. With the freedom of the under 40 volts, you could make the chassis a part of the cabinet.

Nebeker:

And why was that possible?

Harder:

If you are below forty volts you don’t have to follow the rules of high tension. You can’t get any shocks electrically.

Nebeker:

So you can mount components on the piece?

Harder:

You can mount components outside. That was great because the power transistors could be outside. They were actually mounted on the back, and it was not an isolated back part, it was a part of the chassis. So, instead of having an isolated big cabinet, you could make the back of the cabinet a part of the chassis. So, you get tremendous radiated heat. Then the heat generated things you mount outside, so they were out in the free air outside.

Nebeker:

You mean sticking out the back?

Harder:

Yes.

Nebeker:

Is that right?

Harder:

And that drew all the air from it and you could do it because it was all below forty volts. And that was actually the idea of the whole chassis. It was made like a double H, where you had one compartment at a high frequency, one at an intermediate frequency and one power. Then they were screened with aluminum. So you got a radiation separation from these three parts as well. The funny thing is it all became very flat.

Speakers; Beomaster 900

Harder:

That was a totally new break because radios were always towers where you had a dial and you had speakers, but here you could make it very flat and then you had the speakers.

Nebeker:

Okay, so you were saying that the way you conceived the circuit design, it was natural to have these three compartments.

Harder:

Yes. The new technology gave a new freedom and that freedom was utilized.

Nebeker:

Then once you have the circuitry laid out that way, I mean if you're trying to make something that looks like the older things, the speakers might be on top of that or below it or something like that. You also had stereo coming, so you wanted the speakers separated as much as possible.

Harder:

Yes. Because the speakers were mounted on the same frame, on the same part board, so it was real stiff. Then it was added like compression speakers, so everything was very stiff.

Nebeker:

Was this the Beomaster 900?

Harder:

Yes.

Nebeker:

Was it considered to have separate speakers in that?

Harder:

Yes. It came with separate speakers, but in the regular form it had built-in speakers. It was very good because it just had it all, without losing its identity or anything, so it had a tremendous flexibility.

Nebeker:

Okay, so that was something that came later. You were conceiving this as a single unit.

Harder:

They were designed at the same time, with and without speakers.

Nebeker:

I see.

Harder:

But it was introduced with speakers because it would be too dangerous to introduce it without speakers; it was revolutionary enough in itself. The danger could be that if it was without speakers it was strange, with speakers it was interesting. You know it was very broad. And I think that it was at a very lucky time for Bang & Olufsen.

Television and radio markets

Harder:

Everyone had been occupied with black and white television and that was a fast introduction. People spent all their money on television and they didn’t want to buy radios. Then when the television craze was over, there followed a radio boom and, by sheer coincidence, Bang & Olufsen was ready to meet that demand. When I started in '58 there were twelve or fourteen radio manufacturers in Denmark and a similar number in Sweden and Norway. Today there is only one left in the whole of Scandinavia.

Nebeker:

I know that I’ve seen statistics on television sales in Denmark. It went up extremely rapidly at the end of the fifties and by the early sixties probably many, if not most, households had them. The market is saturated for television, so you need a new product.

Harder:

Yes. At the same time, demand for radios was accumulating. Of course, people had less money at that time, so if they bought a television they couldn’t afford a radio.

Technology and radio design

Nebeker:

Now was it a new idea at the time that this would be a shelf radio as opposed to either a free standing or something that goes on a table?

Harder:

Yes.

Nebeker:

And that was because the technology suggested a very flat radio?

Harder:

The technology gave us the possibility. It was engineer driven. It was the first of that type of thing; they were very flat and they became flatter and flatter, and then Jacob Jensen began to make them more flat and more flat and more flat.

Nebeker:

What were the constraints on flatness? I mean obviously when you go from tubes to transistors you remove certain constraints. There was also a transformer constraint.

Harder:

Yes, that’s right.

Nebeker:

Is that the main constraint during that period?

Harder:

I would say that main constraint was that the transistors were at the edge of what was possible at that time. You never knew what you got from the manufacturer of transistors. The specification of what you got was fluctuation.

Nebeker:

Why then move to transistors when, if as you say, their performance was not as good as the tubes in the early sixties?

Harder:

I think that the reason was compactness and a new form.

Nebeker:

You wanted to produce something new and exciting.

Harder:

Yes.

Nebeker:

This is also stereo; people seemed to want stereo and radio...

Harder:

Yes. But I think that ambition was the engineer's ambition. This was not the marketer's ambition. It was the engineers ambition to create something, to see new possibilities and new components.

Nebeker:

That’s very interesting.

Harder:

That was lucky.

Nebeker:

Yes, that was an extremely important product to the company.

Harder:

Yes.

Production

Nebeker:

The Beomaster 900 introduced in sixty-four or marketed in sixty four. What did you then work on?

Harder:

Yes. It was strange because at that time Bang & Olufsen products were produced under brand names. Which today sounds very strange, but I can tell you that Bang & Olufsen televisions were produced under the name ITT. Radios were produced in Finland and Norway and other manufacturers used it. Some of my constructions or designs were produced by other manufacturers. Today the responsible designer is responsible for the production as well. So, when production stops they call him day and night. As I mentioned earlier, there was a certain spread in components, so they were very sensitive to that. Sometimes it’s tough because they were unstable or muted or whatever. Then I had to go abroad and I was sitting there in the middle of the night worrying about how we could get production running again in the early morning. I liked to do it, I think it was great fun and I traveled and I have good contact.

Nebeker:

What was the purpose of the travels?

Harder:

To restart production. To find the bug and to see if you have to correct that and maybe move a wire or something.

Nebeker:

Oh, I see. You were visiting factories elsewhere which were producing your design?

Harder:

Yes, which were producing my design. It was produced not only under the brand name Bang & Olufsen but also under other brand names. It was produced, for instance in Finland and then when the Finnish production stopped they called upon me.

Nebeker:

I know in these large companies these days there are the R & D Engineers, the Design Engineers, the Production Engineers. They’re sort of separate tasks.

Harder:

At that time we were jacks of all trades, all of us.

Nebeker:

So, you had responsibility throughout the construction.

Harder:

Yes.

Nebeker:

Did that go on for many years?

Harder:

No, I think it went on for a couple of years, and then the company found out that its greatest asset was the name, so they immediately stopped production under other brand names.

Exports; product reliability

Nebeker:

Can you recall what year that was roughly?

Harder:

It must have been in 1967. At that time they decided they wanted to export. The first export was done in that way, they told the buy manager “When you are in Paris, why don’t you stay the one day more than you're scheduled to buy, and go out and sell some of it.” He sold and he sold. He found people who wanted to buy one thousand transistor radios in Baghdad or wherever. At that time the quality was lousy. Then the buyer found out we knew nothing or very little about reliability and at that time. We felt the pressure of the Japanese. We were told from some of the guys who bought our stuff that the Japanese could deliver with two percent fault. I can remember that we sacked an agent in the United States, because he was not satisfied with the diminish of faults in tape recorders from two to one fault per tape recorder. We didn’t know how to produce reliability so we had to compensate by introducing a service network. At that time the Japanese had no service network, so they were forced to produce reliability and they actually did that in a very lousy way. In the beginning they did it by provoking faults. They provoked a lot of faults and they got a very good result on the short side, but they cut a lot of lifetime in the product; that was the price. We tried to do both things: to cut the initial faults and to have a long lifetime.

Nebeker:

In other words the testing procedures shortened the lifetime.

Harder:

Yes. Then the company had to establish an international service network. They were looking around for an engineer who had traveled and talked to other people who would ask “Would you like to do that?” It was kind of a difficult decision but I said "yes" and I did it. I think Bang & Olufsen got a very good service network.

Nebeker:

When did that start?

Harder:

It must have been in 1969.

Marketing and management

Nebeker:

I know that in 1960 only four and half percent of Bang & Olufsen's production went overseas, and that grew to already twenty percent in 1962 and rapidly escalated. That change was really a change for them.

Harder:

It was a change, yes. Point one focusing on the brand name and point two gradually focusing on marketing instead of engineering. My further development was when the export manager couldn’t export anymore. Actually, he committed fraud and was kicked out, and then they asked me, could you please clean up in the export department.

Nebeker:

This was after you were Service Manager.

Harder:

I was actually Service Manager at that time and had, of course, reported to the export manager. Then the company found out that they knew nothing about marketing so in 1972 I was sent to INSEAD in Fountainbleu in France to train in international marketing. That was the best thing that ever happened. For twelve years I was the international marketing director for the company after that. I think they, in the inset, got the basis of what Bang & Olufsen is today. You have to understand the strategy which is very simple; it’s a learning curve. It’s a straight line where you take the unit price as a function of produced volume and accumulate it. At that time we were focusing very much on price because we had local competition and now we had gone global. The first thing we learned at INSEAD was that if you play on the same terms as the Japanese you will be dead in two years. So, what you have to do is position yourself. From that came the seven CIDs (Corporate Identity Components) which is a very important part of Bang & Olufsen. When you had defined your identity, then you had to optimize in the triangle between product, communication and distribution. That’s an eternal game all the time. So you establish an identity, and then you have to find your distribution communication and product, and that’s rather tricky. I don’t think so many understood it at that time.

Nebeker:

So you then set up a training program within the company?

Harder:

Yes.

Nebeker:

Could you tell me a little bit about INSEAD?

Harder:

Yes. I think it was established by Charles deGaulle, because he had ambitions for France and he wanted to have the best marketing school and business education school in the world. He said, “I want the best professionals from all over the world.”

Nebeker:

What was the initial program you got there?

Harder:

International marketing.

Nebeker:

For how long was it?

Harder:

It was nine weeks. There were lessons all day long and then before six o’clock the next day you had to make your next move in your simulated company. You had to invest in marketing, and the computer was very crude because new products were delayed and the market didn’t react to it, so it was real life. At that time I was Vice Chairman of the Association of Electronics Manufacturers and we had made a report about the status of the Danish electronics industry. Of course, they felt threatened. It was a very famous American company, McKinsey, that made it. The main conclusion was that you are very good engineers but very poor at marketing. I was asked, "have you got a suggestion to do something about it?" So, for the entire Danish electronics industry I arranged the same type of education available at INSEAD.

Nebeker:

In Denmark?

Harder:

In INSEAD.

Nebeker:

Did many take that opportunity?

Harder:

Yes. But I think only a few benefited from it because they don’t change behavior; they didn’t understand it. Some did. But Bang & Olufsen took the full consequence. I think that was the foundation of it.

Nebeker:

How many Bang & Olufsen people got such training?

Harder:

Fifty.

Nebeker:

Were you the first?

Harder:

No, I think I was the second. Our managing director at that time was the very first. When he came home from it he said "it’s up to you." So, the very first thing I did was to call upon all markets to come to Denmark to a meeting. It was called Beosem and then we tried to make them understand that they have to follow certain rules when they market Bang & Olufsen.

Nebeker:

When did this start?

Harder:

It was in 1972. It was at the same time. I was in charge of that meeting for I think ten years where we developed that. That was very, very, tough in the beginning. When I stood up there and said “we must have equal marketing,” everybody said “yes,” and I was astonished and I was glad until I found out that they all thought we were going to adopt their methods, not our methods.

'Nebeker:

'Now, the idea there is to have a single, corporate identity showing in all marketing?

Harder:

Right. The seven CIDs. You express that identity in whatever you do in communication.

Product pricing

Harder:

The other thing was that you have to have pricing the same all over. Pricing has been very sensitive to Bang & Olufsen because they have always dominated the Danish market. I think that was one of the reasons why the penetration of the Japanese in Denmark was very much delayed compared to the United States and the rest of Europe; Bang & Olufsen is very strong, and in a certain moment we had a market share of I think thirty percent in Denmark. It’s a strange contradiction having thirty percent market share and then being inclusive. This is a contradiction but, in some way, we managed to do it. Thirty percent of the market share takes the right price, and if you went to Germany…

Nebeker:

You mean the German products would be priced higher than the Danish product?

Harder:

Yes, for the same product.

Nebeker:

The dealer is not allowed to sell at a lower price?

Harder:

We have a recommended price and he has to follow that.

Nebeker:

He has to follow that?

Harder:

He can give a three percent rebate, but that was a part of what I said – to find your product distribution and communication – because Bang & Olufsen didn’t have the force to have mass communication, so we had to use word of mouth. That means through selected dealers, which we had to train. But you have to pay the dealer to communicate, so he had quite good margin.

Nebeker:

A company always has a right to wholesale or sell to whomever it wants to, right?

Harder:

Yes, you could not be denied. If you go into and say I want to buy that and then they say, "I don’t like your shirt," that’s illegal.

Link system

Nebeker:

That also holds true for retailers; if they are willing to pay the price that you got an exemption to do this.

Harder:

So that he must either deal with the customer or with another authorized dealer. Of course, that’s very good strategy because instead of selling units, Bang & Olufsen sold systems which fit together. The company is the only one to use the remote control, all products with the same remote control. That’s a very stable thing because if you take a Japanese set, then there’s a dedicated remote control for all units, so on your table in the drawing room you’ll have seven or eight of these damned things lying about. But if you have Bang & Olufsen, you’ve only got one. That means that you are hooked to them. It all triggers into having a firm grip into end consumer. So now, you know Mr. So and So, we have a new record player or CD player and it still fits in your remote control. This is very clever marketing, but it’s a technological problem to make it compatible, backward and forward all the time. On top of that when we had only one remote control – why don’t you use it in all the rooms in the whole house? Bang & Olufsen said you have the whole audio visual system at your disposal all over your home because we have the link system and one remote control.

Nebeker:

What is the link system?

Harder:

That’s where you link everything around. It’s actually a semi-four cable running around the house like a network. Then you just roll the sets up and then you talk together. You can have television sound on your radio and your radio sound on television. You can operate your video tape recorder in the main room and the children's room so they can make believe they have a video tape recorder but they only have a monitor. So, that’s the marketing trick of Bang & Olufsen and the product. Back to the triangle, if you have a product, you must fine tune your distribution and communication all the time. It all started with products with firm identity, equal corporate identity all over the world, and this fine tuning all the time.

Dualism; product exclusivity

Nebeker:

I know there was something about this conflict between holding on to a large part of the Danish market and going to the high end of the market elsewhere.

Harder:

It’s what we call the dualism. We know that sooner or later we had to give up the market share here in Denmark and become as exclusive in Denmark as we are in Germany, Japan and the United States.

Nebeker:

Has there been a price equivalence for a long time?

Harder:

Yes, but it always suggested the retail price when we introduced a new product. But then you always have to adjust for different taxation systems and you always had currency fluctuations and all that. But since 1972, when you saw this, we started with the same price. It’s always very difficult because the competitor hasn’t got the same pricing, and then you had currency fluctuations and all that. So it’s very difficult to maintain, but we always started with the same price.

Nebeker:

But the you could make adjustments if you needed to have a lower price in one country.

Harder:

Yes. And that’s why I’m coming back to Denmark. When Bang & Olufsen had trouble keeping the turnover, they could always compensate in Denmark – just reduce the price a little bit or make a sale or whatever. Denmark has always been viewed as a safety valve. That’s why every time when we try to go up there and be exclusive, there has always been a crisis and then the prices are lowered and we are back to square one. But sooner or later it is going to be equalized of course, that’s the whole trick.

Nebeker:

Well, in a way then I could see this as an advantage – that you have this latent market in Denmark – where if you lower the prices a little bit you are able to sell the product.

Harder:

Well, the week after you have your sale you see.

Becoming an international company

Nebeker:

You were part of this in the early days, this big adjustment to really becoming an international company, producing a product that will be acceptable to consumers from different countries and also satisfy underwriters’ laboratories in the US and similar things elsewhere, figuring out the tax laws and everything else. This must be tremendous task.

Harder:

To find out all these rules and standards. It’s hard to find out how these underwriters and laboratories are, and all the things to get it through and understand it. It’s hard work. I think there was something which was the reverse side of the coin. I think especially in America, if you talk about marketing with Americans, marketing gives the consumer what the consumer wants, and in America you always go for volume. It has been very difficult to convince our American companies that we’re going for a certain segment of the market. They always come back with strange ideas. You can grow that fast, and if you paint the set green, or if you do something, then you can gain enough – it has really been a fight. I think it is very difficult, and we’re often accused of not listening to the market. It was true, and I think that what really is the skill of Jacob Jensen and Jens Bang is that they can interpret the market. They don’t react to it literally as it’s said, but they interpret it and lift it to another dimension which is forward of everything else.

I once tried it in cooperation with our English dealers because the UK was very important to us. It exploded at a certain time, and we had a hundred dealers that said "we want that, and that, and that and it has to look so, and so, and so." "Okay, we’ll do it." So we made notes and we did it. We showed it to them a year or two later and they said, “what rubbish is that?” “That’s what you asked for.” "We could never ask for that kind of rubbish." We could prove they did it, but it never sold. So I think that Jacob Jensen and Jens Bang skill was really to interpret it.

Nebeker:

To foresee what will be a good product?

Harder:

- Audio File

- MP3 Audio

(309_-_harder_-_clip_2.mp3)

Yes. I think the idea grew which we had years ago, where we had Jens Bang with his perception of art and market, with his perception of the whole industry, and Moller Petersen who was an engineer with technology out of this world, and I was representing the market side. The four of us met every Wednesday at twelve o’clock, had lunch together, discussed what we had seen, and Jacob Jensen and Jens Bang put models on the table in front of us. That was very fruitful. And I think we reacted to statistics, but we always interpreted the trend. That meant that we were a little bit before the market and I think the skills of Bang & Olufsen were used a lot. I think because we could see a problem coming up, namely that in the beginning of the industry, you could do everything yourself. We made the tiny screw, the transformations, everything. But today it’s really an assembly line – the components and otherwise, and you don’t, you're not in charge. You don’t master the main components; they are mastered from your main competitors.

Infrared Communication; wristwatch with remote control

Harder:

The only thing that was deliberately developed was Infrared Communication, and that’s the best. The IR communication at Bang & Olufsen is the best in the world. It’s not sensitive to sunlight, it’s much better coated and you can do with it what you could never do with other things. That’s the basic technologies which we developed ourselves, and it was then used to perfection. Actually, one of the ideas of my last project with Bang & Olufsen was to develop a wristwatch with built-in remote control for hi-fi and television.

Nebeker:

This is a Bang & Olufsen project?

Harder:

Yes.

Nebeker:

Is it going to be marketed pretty soon?

Harder:

It has been marketed.

Nebeker:

Okay.

Harder:

But the present management doesn’t want it because they thought it was too odd. So they want to concentrate on something else. But the managing director before, Vagn Andersen asked me to do it. That was my last project assignment.

Daughter companies in Norway and Sweden

Nebeker:

I see. In 1968, I believe it was, the first of these daughter companies was set up in another country?

Harder:

Norway and Sweden.

Nebeker:

What was the rational for that? Why not just continue to have dealers in the other countries?

Harder:

The first rational was that, sooner or later when you have an agent, you run into trouble because the agent wants to have a comfortable life. That means small volume, high contribution. Then, when you squeeze him for contribution not for volume, he doesn’t want it.

Nebeker:

What is the function of the daughter company?

Harder:

At that time it was to have a service workshop, a stock, and to be the basis of sales people: four, five, six people.

Nebeker:

All dealers selling Bang & Olufsen in these countries would get their supply from this company? Their service would be provided through them?

Harder:

Yes. And they produced all marketing materials, catalogs and advertising.

Nebeker:

I see.

Harder:

So what we gave them was the framework for catalogs. Catalogs were always made in Denmark, but then there was national adaptation in Norway and Sweden, and that was their function to do that.

Product service and the U.S. market

Harder:

The main problem at the time when we started was service. That was, as I said, a result of poor reliability due to the Korean War. The G.I.s in Korea often went to Hong Kong when they had their leave, and they always bought hi-fi. Bang & Olufsen was at that time very well represented in Hong Kong. They bought it in Hong Kong and when they came home from Korea they found out it didn’t work in the United States. Then we had the problem that we had no organization in the United States. So, our international subsidiary in the United States was actually asked to introduce a service workshop just to repair things that G.I.s had bought in Hong Kong.

We didn’t know anything about the US, but we saw a market and I think the strategy was very clear. Of course, at that time, our stereo console was world famous and it was a tiny product. Then from the basic of the service workshop they started selling it. We had a very devoted president, and he went to the local radio stations with our pick-up cartridge, and it was very good. It was the world's best. We had a tremendous sales pick up in cartridges, and then we were stuck at the moment because so far we had no trouble with the UL approval or the loud speakers. But then we frankly added hi-fi amplifiers and a record player.

U.S. television market; standards and picture quality

Harder:

Then there was a tremendous demand for television in the United States. It was forced upon us when US dealers visited us as part of our training. At one time there were three hundred American dealers over here for education. They came and saw that television and they saw a wonderful picture and said, “we want your television” and we said, “it’s not possible.” After many years we said we'd give it a try.

Nebeker:

When did this start?

Harder:

- Audio File

- MP3 Audio

(309_-_harder_-_clip_3.mp3)

I think it must have been mid-1980s. At that time I was not marketing director anymore, but I was in charge of our lobbyists, so I had the contact with everyone in Brussels with the World Trade Association for the Danish Government. I spent days every week in Brussels talking to them and in the annual negotiations between European Industries and Japanese Industry. I was presenting the European part of it. Then I went to the United States, and you know your television system has a very bad reputation over here – you know the old joke, never the same color twice. I know you’ve heard it a thousand times. I had a very strange experience. Of course, with the help of the Danish Consulate General of the United States I got access to everything in the United States. I had the vice-council with me. I started in Chicago and went to one of the big coast-to-coast networks and went out to the camera man and asked, “Why do you produce such lousy picture?” He was very mad because he was a proud man and he could show me that his picture out of his camera was perfect. Then I went to the mixing room and asked “Why do you spoil his picture?” He was very mad, and I went through all the chain. I was standing on the truck of Sears and Roebuck and the antenna then said "good-bye signal," and it disappeared. We went home and we actually borrowed an NTSC transmitter from Phillips in Eindhoven, Holland. I had an engineer who was extremely clever in television, and we borrowed this transmitter from Phillips, and we brought the whole NTSC standard back home from the United States. He sat down and he designed a set where the picture was perfect. You couldn’t see a difference between the European picture and the NTSC picture, and we were very proud. Then we took it and flew it back to Chicago and we tried it in real life. We were so much looking forward and we were terribly disappointed because it was a lousy picture. After a couple of days frustration, the engineer said to me: "The reason appears to be that the Chicago transmitter was sending off standard." In Europe this is very, very serious: to send off standard. Every station master in Europe is proud that his transmitter is top tuned all the time; he is checking it all the time. We took the elevator up to Sears and Roebuck, knocked at the door to the station master there and said, "You're driving off standard, right?"

Nebeker:

What parameters were up standards?

Harder:

I can’t remember it all, but it’s a very strange story and it’s a very sad story for Americans. In Europe this would never happen. So we discussed it with him and we understood everything. When he went back to standard the picture was beautiful. But it didn’t work because he wouldn’t do it in daily work. The reason appeared to be that his salary was depending on his cost so he said, frankly, “when nobody complains, I don’t spend money correcting it.” Then you are in a very, very big circle. The producers in America know the signal is lousy and therefore there’s no reason to make the set perfect, and then the transmitter said, “it’s a lousy receiver why spend all this money?” And then it was a wicked circle. That’s a part of the American system. Actually, it was dangerous. I think it is corrected today because today the American user has other signal sources than off air or off cable, because they have got records and they have videotape. So, you have to bring the performance of the set up to spec, and your system isn’t bad at all. It has a few weaknesses, but it’s easy to compensate. We actually managed it and we started introducing it in the United States in television. We had to demonstrate it on disc because there was not a good signal available; we could tell Americans what skin color was. They had never seen that on television. But, the project was stopped after two years; we couldn’t find distribution.

Nebeker:

Even though these dealers had said they were interested in television?

Harder:

They couldn’t sell the volume. The American consumer was not accustomed to buying a television in the hi-fi store. They always went to K-Mart or something similar. We produced and marketed for a couple of years.

Nebeker:

I see.

Harder:

It’s still a joy to see. But, we couldn’t find a distribution that could justify the price because it was much more expensive. It was produced in Mexico actually, in cooperation with Hitachi. I did a lot in Japan. It appeared I was responsible for our sales in Japan in that period of time, so I know something about Japan and made the corporation agreement with Hitachi.

International corporate alliances and production

Harder:

I would say Bang & Olufsen would sooner or later need a strategic alliance, because of the fact that they didn’t have access to main components anymore at an early stage. Of course, as a result of the terrific concentration there is no consumer electronic industry in the United States anymore, not American owned. In Europe there are only a few left: Phillips, Thompson and Bang & Olufsen. Then there are the six or seven Japanese and three Korean ones. But it appears that all your suppliers are also your competitors. That means when you say, "we want to buy a picture tube from you," then the marketing department says, "that’s fine for us as long as you give me last year's model." The only way out of this is to have a strategic alliance. Our company has always been very proud that they earned their own money and that they were free for many things. I actually did the leg work for the strategic alliances. I went down for the INSEAD and talked to them about it because they knew it and they had mapped out all the alliances in the whole world and in all industries. I found out that actually Sony is a very strange company. At that time they had no alliances. Sony has always earned their money, doing everything by themselves. They are not a member of a banking group or a conglomerate or anything else.

Nebeker:

I was going to ask about ... I thought that always all production was here in Denmark.

Harder:

It has always been except for the videotape recorder. They were produced with the cooperation of Hitachi. The problem there, and that’s where you can really see the problem, is that when we negotiated with Hitachi they always wanted to do business with us. All Japanese have done it all the time. Of course, Bang & Olufsen are very interesting and the Japanese don’t understand it. The Japanese do not understand the emotions as we do it, and unpredictable things, and therefore we’ve always been of interest to them, and they want to do business with us.

Nebeker:

How long did you work as Sales Director or Marketing Director?

Harder:

Twelve years.

Lobbyist position

Nebeker:

What did you do then?

Harder:

I became the lobbyist. One of the reasons for that was that Bang & Olufsen could see the Common Market coming up as a stronger and stronger element in the daily life.

Nebeker:

How long did you have that job, the lobbying?

Harder:

Five years.

Retirement

Nebeker:

So when did that end?

Harder:

It ended when I turned sixty because I had to leave the company when I became sixty.

Nebeker:

Is that a company policy?

Harder:

It became a policy because the company had a crisis. The company had thirty three hundred people and they had to get rid of seven hundred. They said: okay everybody at sixty has to leave.

Career progression from engineering to marketing and management

Nebeker:

You were of course an electronics engineer, then became marketing director and this other job. Were those things you really were attracted to?

Harder:

Yes. Basically I don’t think I’m a very good engineer, which might sound very strange. I think on a total level I’m a good engineer but it bores me, all details.

However, my father was a very good salesman, my grandfather was a very good salesman.

Nebeker:

So, you were even better at sales.

Harder:

I think so. What I found out was that my credibility as a salesman was great when I had my engineering background.

Nebeker:

Do you think that that’s sort of your image? You were an engineer coming out of the engineering department and as you say that benefited you, at least your image as marketing director. Do you think that it really was beneficial in the way you made decisions and so on with your engineering background?

Harder:

It was because I could interpret what the market said, not only react to it.

Nebeker:

You could see what the technological trends were?

Harder:

Yes. And, I could read the development behind the commercial language. I think what was very important was to distinguish between the design buzzword from marketing, or a real heavy technological trend. If you go to the CE show or the Tokyo show, you’ll see numerous new products. It’s like washing powder, and they always have something magic there.

Nebeker:

So a person straight out of business school, or a person who has even had a lot of experience in sales and marketing, just wouldn’t be able to function as well.

Harder:

No. And maybe today you have to have another background. It’s not so technology driven anymore.

Japanese market

Nebeker:

We have a little more time and I wanted to ask you about your experiences with Japan, and Bang & Olufsen's experiences with Japan.

Harder:

For many years we had an agent in Japan. If I could do something all over again I would be more selective in the way we started marketing abroad. I would really use a roll-out company, and I would have done that in the United States. We were so naive. We should have started to conquer New York, and maybe from the west coast, and then have a roll out. I think we were thinking like Frank Sinatra when he says things about New York; if you can do it there you can do it everywhere. We were not satisfied with our agent in Japan. So we established a daughter company after that.

Nebeker:

How was that done?

Harder:

We simply found an office space. It’s very strange to deal with the Japanese because they never say “no.”

We did a lot of meetings in Japan. I was sitting there all alone and they had seven or eight people sitting in hierarchy order. What’s going to be interesting is the market doesn’t respond to price decrease anymore and I know they have serious problems. So it’s interesting to see what’s going to happen.

Nebeker:

Well thank you very much.

Harder:

Thank you.

[End of interview]