Slips and Jars

The original version of this article was created by Francesco Gerali, 2019 Elizabeth & Emerson Pugh Scholar in Residence at the IEEE History Center

It is recommended this article be cited as:

F. Gerali (2019). Slips and Jars, Engineering and Technology History Wiki. [Online] Available: https://ethw.org/Slips_and_Jars

Slips were well drilling devices used for the first time with a spring pole system, the early manual percussion drilling technology used in the United States beginning in the early 19th century. Slips were introduced between 1831 and 1832 by William Morris, blacksmithing tool manufacturer and salt driller from Kanawha Salines on the Great Kanawha River, West Virginia. Afterwards, slips were also called jars from the drillers of the Oil Regions of Western Pennsylvania. The latter name became predominant after the 1860s, when Pennsylvania was distinguished as the primary site for engineering and production of petroleum technology in the world. Slips were industrially forged and marketed as jars and the name still stands today in the technical language. [1]

The first slips purchase was recorded on August 1st, 1832, a pair forged by Morris and sold for $2 to Joseph Ruffner and his brother David.

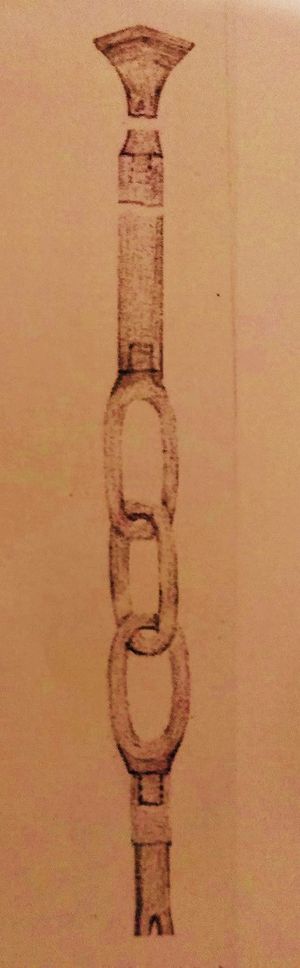

The conceptual function of slips is considered a major improvement in early drilling technology, being useful to dislodge the drilling tools stuck in the borehole. They consisted of a short chain of three iron links inserted between the bottom of the drilling cable, or wooden rod depending on what was used by the driller, and the top side of the drill bit, the chisel. A few links of the big chain in the drilling string would slacken as the drill bit hits the bottom and picks up the drill bit on the upstroke. This invention, together with the adoption of the heavy sinker and some other minor improvements in well boring, gave momentum to deep boring in the Kanawha River region. Soon brine wells were put down from 500 to about 2,000 feet.

Morris secured his invention with a patent and a second one was reissued in 1841, following the great fire that destroyed the Patent Office in Washington D.C., this time including important improvements to the whole system, patented this time as jar. The original chain links originally patented tended to wear excessively and this problem was addressed. Morris' 1841 device, now evolved into an articulated joint, is presented as a manner of uniting augers to sinkers for boring an artesian well. It is a long double-link with jaws that fit closely but slide loosely up and down. They are about 30 inches long and fitted top to bottom with pin a and socket joint. For use they are interposed between the heavy iron sinker, with its cutting chisel-bit below, and the line of augur poles above. Its object is to allow the heavy sinker and bit to have a clear, quick, cutting fall, unobstructed and unencumbered by the slower motion of the long line of augur poles above. In the case of a fast augur or other tools in the well, they are also used to move the heavy jar upward or downward, or both, to loosen them, and from this latter action the name shifted to jars.

The Pennsylvanian petroleum boom and the subsequent new need for drills leveraged dramatically on the transfer of drilling technology developed in the brine and sweet water fields near the petroleum wells. Jars soon became a standard indispensable device in the sets of downhole tools used by drillers.

The patents of Morris were soon surpassed and great steps toward the optimization of the technology were made in the 1860s. The first swedged and crutched 6-inch stroke rectangle steel reins with knocking heads and cap ends forged in iron for the pin and box joints on jars were produced by Gibbs and Sterritt, petroleum drilling tool makers in Titusville, PA, in 1865.

The jars made with solid steel reins with a four to six-inch stroke were called short stroked jars. The fishing jars were usually made of iron with steel lined reins or links, with a stroke from three to six feet were called long stroked jars.

At the end of the 19th century, the style and make of jars were considered very difficult to manufacture, and required high quality steel, as well as workmanship. The maker of jars was usually known as a "jar maker", first-class blacksmiths much appreciated and requested throughout the oil regions of Pennsylvania.

Images

See also

References

Anonymous. “Early Drilling When Oil or Gas Was Looked Upon as a Nuisance”. The Oil and Gas Journal, June (1923): 118.

Brantly, John Edward. History of oil well drilling. Houston: Book Division, Gulf Pub. Co., 1971.

Eaton, S. J. M. Petroleum: a history of the oil region of Venango County, Pennsylvania. Philadelphia: J.P. Skelly & Co., 1866.

Kemp, Emory Leland, and Michael W. Caplinger. 19th century petroleum technology in North America. Morgantown: West Virginia University, 2007.

Oil Men's Association of Butler County, and Oil Men of Western Pennsylvania. 1907. Oil region reminiscences: souvenir, twenty-first annual gathering of the Oil Men of Western Pennsylvania at Conneaut Lake, Thursday, July 25th, 1907. Butler, Pa: Oil Men's Association of Butler County.