Pump Jacks

The original version of this article was created by Francesco Gerali, 2019 Elizabeth & Emerson Pugh Scholar in Residence at the IEEE History Center

It is recommended this article be cited as:

F. Gerali (2019). Pump Jacks, Engineering and Technology History Wiki. [Online] Available: https://ethw.org/Pump_Jacks

Beginning in the late 1850s, walking beams were the most common pumping well devices used in the petroleum fields of Pennsylvania, West Virginia and Ontario. This apparatus was already used in the sweet water and salt mining industries and was transferred in the early petroleum fields, like it was for derricks, drilling bits, boilers, and many other field equipment. The wooden walking beam, the rocking arm, was pivoted in the middle on top of a Samson Post. On the back end of the walking beam was a counterweight, which often was a wooden box filled with rocks. Behind the box was mounted a pitman, which raised and lowered the pump in the well. The pitman runs from the outer edge of the band wheel, the characteristic large wooden wheel spinning at the back which connect the pump to a steam engine, to the back end of the walking beam. As the wheel rotates this pivot arm causes the beam to rock back and forth, thus moving the sucker rods up and down. On the front end was the polish rod (or sucker rod), that runs through the casing head to move down into the well hole. The rod is connected to the pump that sits in the section of the well immersed in petroleum. When the sucker rods push down on the pump, a valve on it opened up so that as the pump moves down, petroleum can flow into the chamber above the valve. When the upstroke begins, the valve closes and the petroleum shifted above the valve is then lifted upward. At the same time, petroleum from the reservoir moves into the void beneath the valve, and as the down stroke begins the valve opens back up; in doing that, the cycle began anew and petroleum is lifted to the surface, one upstroke at a time.

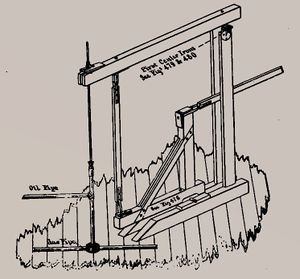

In the 1870s-80s, the metal device named pump jack, first conceived by Plackross in 1877, replaced the wooden structure that served the early industry so well, and it then spread over the south and west of the United States. The pump jack uses the same principle of the walking beam, converting the shackle line’s horizontal reciprocating motion to a vertical reciprocation motion. In the 1880s, pump jacks they assumed numerous configurations but nearly all were classed as either "direct lift" or "indirect lift." Each type relied on a vertical triangular frame or "knee," with one comer connected to the shackle line, one to a pivot mount, and the other connected directly, or indirectly, through a steel pitman and walking beam arrangement, to the polished rod.

On direct lift jacks, a curved mount at the polished rod-end of the knee (or walking-beam in the indirect type) allowed for a straight, vertical pull on the polished rod. Direct lift jacks were classed either as underpull or overpull depending on the level at which the shackle line connected to the jack.

The length of the stroke imparted to the sucker rods could also be adjusted at the jack. Popular direct-lift jacks included the Hudson jack, Jones & Hammond jack, Simplex jack, Bessemer jack, and Norris jack. The indirect-lift jacks were sometimes called Pennsylvania jacks as they were first used in this state. However, the Oklahoma jack was the most popular type of indirect lift. Other types offered by manufacturers were the O.K. jack, the Paova jack, and the Maloney jack. But indirect-lift jacks were in petroleum industry the commonly all referred to as Oklahoma jacks. Another type of jack consisted of a grooved wheel mounted vertically, on which a cable shackle line made a 90-degree tum from horizontal to vertical and then attached to the polished rod.

Manufacturers offered different types of jacks built in wood, cast parts, structural steel beams, tubular steel, or other combinations of material. Sometimes, to save time and money, the pump jacks were built on site by the operator using scavenged materials.

See also

References

Bacon, Raymond Foss and William Hamor. The American Petroleum Industry I. New York: The McGraw-Hill Book Company, 1916.

Ball, Max. This Fascinating Oil Business. New York: The Bobbs-Merril Company, 1940.

George, H.C. Surface Machinery and Methods for Oil-Well Pumping. Department of the Interior Bureau of Mines Bulletin 224. Washington, DC: Government Printing Office, 1925.

Ross, Philip. Allegheny Oil: The Historic Petroleum Industry on the Allegheny National Forest. Warren, Pennsylvania: United States Department of the Interior, Allegheny National Forest, 1996.

Ver Wiebe, W.A. North American Petroleum. Ann Arbor, Michigan: Edwards Brothers, Inc., 1957.