Oral-History:Syd S. Peng

About Syd S. Peng

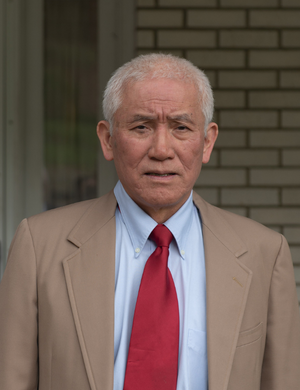

Dr. Syd S. Peng is Charles E. Lawall Chair of Mining Engineering emeritus, Department of Mining Engineering, West Virginia University (WVU), Morgantown, WV, U.S.A.

Dr. Peng received his undergraduate diploma in mining engineering from National Taipei University of Technology (NTUT) in Taiwan. He went to the U.S. in 1965 for advanced study and received his Ph.D. in mining engineering from Stanford University in 1970.

From 1970 to 1974, he worked for the U.S. Bureau of Mines, Twin Cities Research Center in charge of rock physics research. He joined WVU in 1974. In 1978 he was appointed as chairman of the Mining Engineering Department, a position he held until September 2006. He served again as interim chair in 2015. He retired from WVU in 2013.

In 1985, he established the Longwall Mining and Ground Control Research Center and assumed its directorship. In 1998, he was appointed director of Coal and Energy Research Bureau, state of West Virginia. He has supervised more than 100 research projects with more than US$12 million from government and private sources. He has performed research in more than 300 mines in coal and industrial minerals in all US mineral-producing states and 16 foreign countries. He has successfully supervised 39 PhD dissertations and 47 MS thesis.

He established the annual international conference on ground control in mining in Morgantown, WV, in 1981 and served as its proceeding’s editor and co-editor until 2010. The conference has become the annual forum for worldwide experts on ground control in mining and spun off a similar conference in China since 2014.

He has written several textbooks and published more than 380 conference proceedings and journal papers in the areas of longwall mining, ground control, surface subsidence, respirable dust, modeling, and mine seal. His research emphasized both theory and practice, i.e., theory is validated with mining practice, and mining practice is based on sound theory.

Further Reading

Access additional oral histories from members and award recipients of the AIME Member Societies here: AIME Oral Histories

About the Interview

Syd Peng: An Interview conducted by Steve Tadolini in 2022 in Morgantown, West Virginia.

Copyright Statement

All uses of this manuscript are covered by a legal agreement between the American Institute of Mining, Metallurgical, and Petroleum Engineers and Syd Peng, dated May 19, 2022. The manuscript is thereby made available for research purposes. All literary rights in the manuscript, including the right to publish, are reserved to the American Institute of Mining, Metallurgical, and Petroleum Engineers. No part of the manuscript may be quoted for publication without the written permission of the American Institute of Mining, Metallurgical, and Petroleum Engineers.

Requests for permission to quote for publication should be addressed to the American Institute of Mining, Metallurgical, and Petroleum Engineers, 12999 East Adam Aircraft Circle, Englewood, CO 80112, and should include identification of the specific passages to be quoted, anticipated use of the passages, and identification of the user.

It is recommended that this oral history be cited as follows:

Syd Peng, “Syd Peng: A Global Leader & Problem Solver for the Mining Industry,” an oral history conducted by Steve Tadolini in 2022. AIME Oral History Program Series. American Institute of Mining, Metallurgical, and Petroleum Engineers, Denver, CO, 2023

PART 1

PART 2

Interview

INTERVIEWEE: Syd Peng

INTERVIEWER: Steve Tadolini

DATE: 2022

PLACE: Morgantown, West Virginia

PART 1

00:13 INTRODUCTION

Tadolini:

Today is May 19, 2022. My name is Steve Tadolini, a former student, colleague, and, more importantly, a mentee and friend of Dr. Syd Peng in Morgantown, West Virginia. As many of you will know, Syd is the Charles E. Lawall Chair of Mining Engineering Emeritus at the Department of Mining Engineering at West Virginia University. Syd started at WVU in 1974, and we will get into details of that incredible 28-year run as the department chairman. Syd is also a member of the US National Academy of Engineering. He was elected in 2006 and continues to actively participate. But, he's probably most well-known for the creation and successful operation of the International Conference on Ground Control in Mining (ICGCM), which started in 1981 and is held annually, with the 41st annual conference being held this year.

We are doing this capture for the American Institute of Mining, Metallurgical, and Petroleum Engineers (AIME) Oral History Program. Thank you, Dr. Peng, for agreeing to talk to us today and share your experiences. So, let's start at the beginning. Tell me about where you grew up and what your early life was like.

01:30 GROWING UP IN A RURAL TOWN IN TAIWAN – WATER LEAKS & SPRINGS

Peng:

I was born on January 27, 1939 in a very remote, rural town in the midwest in Taiwan. I’ve got two brothers and four sisters in the family. My father was a carpenter, and my mother was a housewife, and I also had my paternal side grandmother living with us. I was born in a, I would call it, a somewhat broken house; we rented from our neighbor. Whenever it rained, it leaked. The room leaked; the wall leaked. You know, I had to do a lot of things to bail the water out of that. When I was young, really, I did a lot of household chores to help with the family. For instance, we didn't have any running water at home; so, I had, every day, to go to a spring well, maybe one or two kilometers from the home, to carry the water back home for the family to use.

02:54 CHORES FOR MY GRANDMA – CATCHING FROGS IN PADDY FIELDS & SWIMMING IN THE RIVER

Peng:

Also, my grandma, she raised chickens and ducks for her business, and I think she earned some petty cash from it. And, during the daytime, she put all the chickens and ducks outside, just right outside the house. But, during the night, she was afraid of them being stolen by outsiders. So, she moved the chickens and ducks into the living room. Every day, every morning when I got up, I had to sweep the floor, you know, the whole house, including all this dirty droppings left by the chickens and ducks [in the living room. Cleaning the droppings was the toughest part, not only it smells terrible but also it sticks stubbornly to the floor.] The other thing my grandma wanted me to do is, every day after school when I got back home, she would ask me to go to the paddy field, which was about three kilometers away from home. And, she wanted me to pick up the lotus leaf or go catch the fresh frogs in the paddy field and bring them back for the chickens and ducks, you know. But, since Taiwan is warm in the winter and hot in the summer, every time after I was done with the work, I jumped into the river. The river surrounded the paddy field, and I'd play around in it before I went home. And, that's why I really liked, to swim every day. In fact, since I came to West Virginia in 1974, I swim every day. Even now, I swim every day.

Tadolini:

And, you swam today?

Peng:

Yes.

05:03 TAIPEI TECHNICAL JUNIOR COLLEGE – #3 IN THE MINING ENGINEERING PROGRAM ENTRANCE EXAM

Tadolini:

If I remember correctly, to continue your education beyond junior high, you passed entrance examinations to two schools: Taipei Technical Junior College [Taipei Institute of Technology, the official name] and Taizhong First Middle Senior High School. What was going through your mind, and who or what influenced you to become an engineer?

Peng:

Well, in Taiwan, first let me talk about the education system. The education system in Taiwan is quite different from the US, and the way they go is from every level – for instance, from elementary school to junior high, then junior high to senior high, senior high to college – every level you need to pass an examination of the schools that you want to get into. So, when I finished my junior high school, I took two exams to do school; one in the north of Taiwan, Taipei Technical Junior College, and the other one in the middle of Taiwan, a senior Taizhong high school. And, I passed both of them, and I was admitted to both schools. Well, the bottom line is, I chose Taipei Technical Junior College and thus a five-year mining engineering program. I think my father's goal was to have me as a college graduate. It was certain that I wanted to, too, because I would be the first generation to go to college, go to university.

So, I figured, if I took the technical junior college, I needed five years to finish to get my degree. If I went to the high school, senior high, then to college, I would need seven-years to finish college. So, the two more years there, I needed to pay more for the two more years' tuition and school expense. I think that's a lot of burden to my parents, so I figured I didn't want to do that. So, I chose Taipei Junior Technical College. What I didn't know, and my father didn't know then, was that a technical junior college is not the same as a college. You don't get a degree; you only get a diploma.

I didn't know that back then, you know. So, that's what we chose, a technical college. And also, we were from a small school in the middle of Taiwan, and Taipei Junior College is a big, big city school. So, as a teacher advised us, they said mining engineering has less competition in the entrance exam, so you should register for that as your major. Well, that's how I chose the mining engineering program, five-year mining program. Well, it turned out when the school started, during student orientation, the teacher told us that there was about 600 plus students who took part in the examination for the mining engineering program, and I ranked number nine, and that was really good. I was tickled with that.

08:31 VIETNAM MILITARY SERVICE – SHINCHU COAL MINE

Tadolini:

Your first job, after 18 months of military service during the Vietnam period, was at Shinchu Coal Mine Development Corporation. What were your duties, and is this what led you to your passion of coal mine safety?

Peng:

When I finished at the college in 1959, it ended with having the government requires all college graduates to do military service. So, I served about one-and-a-half-year military service and retired from the Army in January 1961. And then, in February 1961, I took part in the placement examination by the government, and I passed it. So, they assigned me to Shinchu coal mine, which is a government operated coal corporation. And, the mine is located in north central Taiwan in a very remote mountainous area. I mean “remote”, because it's isolated from the rest of the world. I reported to Shinchu coal mine to work there in the summer of 1961.

They assigned me as a junior mining engineer, and my job was to go into the mine every day. I’d go to the mine face to collect samples and come back to the laboratory to analyze what type of coal, what composition – any change of that thing. People would make a decision about what the coal quality was supposed to be. The coal mines in the Shinchu coal mine, there are three portals. Two portals are right around the headquarter area. And, in the third portal, the newest one, was almost, every day, an hour walk from the headquarter, and there are many mountainous slopes you had to walk up and down to reach there. The mine portal was in a very steep valley slope.

The mine mined the high-quality coal, and the coal seam was 4-16 inches thick with occasional 1m or more thick pockets. It was 300-400m deep. Such seams of poor geological conditions would never be considered economically viable in US coal industry.

In terms of mine development, what they did is that they first developed a slope shaft from the surface following the dip of the coal seam which dipped about 20-25 degrees, all the way into the mountain. In about every 100 meters, they developed a horizontal drift of variable length on both sides of the slope.

11:28 GAS OUTBURSTS & MINE FATALITIES – INVESTIGATING SAFE MINING PRACTICES

Peng:

The problem with all these miners is that there is the gas outburst. Once it occurs, it's just like what we call the rock burst. The gas and coal are ejected with a very strong force, and a lot of people get killed. In fact, I worked there three years, there were 16 people killed because of the gas outbursts. And, the other two portals near the headquarters had a better safety record, but not much better. In fact, the year I came to the US, in 1965, the mines had a total of 15 fatalities.

As I said the mines were in very remote areas, all this story of fatalities and injuries, the outside world didn't know that because it's so far away from the public. So, that's why it really shook me a lot. So, I started investigating into what are many things in mining, what are gas outbursts, you know, and can we do something about it?

In the five-year mining engineering program at Taipei Technical Junior College, we read all the US textbooks, including Element of Mining by Lewis Clark. But, they never mentioned a thing about safe mining in very thin coal seams, never mentioned about gas outbursts.

13:07 A DREAM COME TRUE – STUDYING IN THE US AT SOUTH DAKOTA SCHOOL OF MINES & TECHNOLOGY

Tadolini:

Well, eventually you applied and were accepted in the South Dakota School of Mines and Technology in Rapid City, SD. I can only imagine that trip to the US coming from a small town in Taiwan. Can you tell us how you came about this opportunity, who influenced you, and how you came to the US?

Peng:

I wanted to study the things in thin seam mining and gas outbursts and how to control it, in order to help the mine reduce the fatalities. So, the first thing I know at that time is to go to Taipei's US information service [United States Information Agency], and they have a big office and a big library there. So, I went through their library in order to see if there was any literature there I can use. Well, I found nothing about it, but I did find the US Bureau of Mines. US Bureau of Mines was doing research for mining for the US. So, I wrote a letter to the Director in D.C., Washington, D.C., and explained to him what I wanted to do. I asked him if he can help.

The Director didn't respond, but it was – I remember well, Mr. William Crentz. He was a branch chief in the headquarter, and he responded to me. So, we started communicating, and every time he sent me a lot of the US Bureau of Mines bulletins, reports. But, none of them really could help me on the safety in thin seam mining or gas outbursts, all that. So, I asked a lot of more questions. I guess he probably was bothered by me, by all these questions. So, he told me, he said, "Why don't you come to the US to study for yourself, and you can find a solution better." I said, that's a good idea.

For me that was a kind of dream, you know. He applied for the graduate admissions for me. One was South Dakota School of Mines, and the other one was University of Missouri, Rolla. But, I heard the University of Missouri, Rolla has a lot of Taiwanese students, and many of the non-mining classes have a lot of Taiwanese students there. Well, I figured that situation could be just like in Taiwan. it couldn't help my English at all. So, I told William Crentz, I'm going to South Dakota, because it's a small school. I think I want to have more chances to improve my English. Even though South Dakota, at the time, I know pretty well ranking-wise, was much lower than University of Missouri, Rolla. That's how I went to South Dakota.

16:17 BETHENERGY COAL CORPORATION – FIRST JOB IN THE MINING INDUSTRY

Tadolini:

Did you take any internships or have other experiences during your schooling that shaped your interest in the mining industry?

Peng:

Yes, in the business (or study-wise), you can see I was so unprepared, and I really didn't know much about schooling in the US. So, I arrived in the US, I remember at South Dakota's school on May 5th, 1965. The school was about two weeks from summer school. So, when I went to see Professor Oshier, the department head and my academic advisor, he said, "School is over in two weeks." He said, "It's summer. We don't have summer school. I don't know what you can do. But, if you want to study, I can give you a book or two, and you can read it. Start reading, prepare." But, he said, "it wouldn't count for your degree program."

Well, I figure if it doesn't help me in the degree program, and since I need money for the school, I said, "I want to go to work somewhere." So, I wrote a letter to Mr. William Crentz and asked him to help. He responded right away. He told me, “Yes, you can come over.” So, I came to his laboratory with BethEnergy Coal Corporation in Johnstown, Pennsylvania. And so, I took me another Greyhound bus from Rapid City, SD to Johnstown, PA. His laboratory does the coal sample analysis, and, believe it or not, it's exactly the same as I did in Taiwan. So, really, it didn't help me that much in terms of professional development.

18:35 HOMESTAKE GOLD MINE – BECOMING A TEAM LEADER & BEFRIENDING STANFORD PERSONS

Peng:

After the summer, I went back to the school for the school year. And then, in the summer of 1966, I found a summer job with the Homestake Gold Mine Corporation in Black Hills, SD, which is about a 40–50-minute drive from Rapid City, South Dakota. I worked in the underground first, and I remember at that time it was 7000 feet deep. The place is so hot, you know, for the people working there it was really bare (or naked), because it's so hot. About two or three weeks after, they pulled me out and said, “Well, we have this geological exploration program we want you to do, go there to help us.”

They transferred me to the surface, and then on the surface I was a team leader to a team of two persons. We just went around in the Black Hills along the assigned trails or directions and took samples, soil samples, and brought them back to the laboratory. We also analyzed how much gold content would be there in the samples for the exploration. The exploration group at that time, consisted of mainly from Stanford University persons; "Stanford kids" I called the kids, also including Stanford professors. They were really very knowledgeable; I was very impressed. So we all became very good friends, including the graduate student and professors, too.

And so, in this respect, these two jobs, summer jobs, were not as much as what I was wanting to be doing as my career. But, I have to say, the money I made, it really helped me out. Otherwise, I couldn't finish my master's degree in one and a half years, or something like that.

21:06 PHD AT STANFORD UNIVERSITY – “THE ONLY SCHOOL I APPLIED TO”

Tadolini:

When you completed your BS and MS at South Dakota, how did you end up going to Stanford University for your PhD? You mentioned that you had some colleagues that worked at Homestake. How did that take place?

Peng:

Before I came, when Mr. William Crentz asked me to come to the US to study for myself, at that time I figured out myself, I think I need to get my PhD degree. I want to get a PhD, but I need to get in within five years because, mainly, it was a money consideration. Because I had to borrow, my family had to borrow all these funds for me to come to the US to study more. One more year study is one year more interest to pay, one more example, all that kind of thing. So, I decided that my plan is five years to get a PhD first. Second, I figured that in one's career, the highest degree you earn, it usually stays with one’s career. So, I figure if I go to South Dakota School of Mines, that's a small school nobody knows. If I say I graduated from South Dakota School of Mines, probably in my career a lot of people would say, what, where is the South Dakota School of Mines? So, I figured my PhD school, the school where I get it, should be a very good, big one and a reputable one.

When I worked in the summer in the Black Hills, as I said, I know there's the Stanford guys, professors. But, the team leader, Woody, he's a team leader, he's a geology professor, and he was nice. Before we leave for school, he told me, he said he liked me. He would encourage me to apply to Stanford, and he would be very glad to recommend me for the school. So, when I go back to school after summer, I started to study what is at Stanford, at that time. So, I found out, if I went into the field of ground control – at that time, it really actually is rock mechanics, I need to study rock mechanics, applied mechanics, I need to have a very good, strong background in geology, too, because it's rock, and I'm a rock mechanic.

So, I studied what Stanford offered thoroughly. I found out many subject areas at Stanford University ranked number one and two in the US. Either applied mechanics, computer sciences, geology, geophysics, but I wanted to pursue basic science. I said, that's a good school, I see, I need to go. So, I told Woody, he recommended me in there, actually, in the School of Earth Science. That's how I got in there, and this is my only school, the only school I applied to.

24:39 A SERENDIPITOUS LOVE STORY – THE CAMPUS QUEEN & THE UNKNOWN SOLDIER

Tadolini:

Good you got in. Probably the best thing that happened at Stanford is you would meet Felicia, who you married while in school. Can you tell us a little bit about that courtship and share some stories of you and Felicia at Stanford?

Peng:

Yes, Stanford is a landmark in my career. Felicia and I went to the same school in Taiwan, Taipei, Technical Junior College, and graduated in the same year, 1959. The only difference is, Felicia, she finished her senior high and then passed examination to get into the technical college. So, she only needed three years. On the contrary, I finished only junior high, and so, I took the five-year mining engineering program. She took the three-year textile engineering program. So, we graduated same year, 1959. Felicia was very well known in her years in the college because she was very active, and she excelled in extra curriculum. She was on the university track and field team, and she was in the university choir, and all of that. Almost, I would say, everyone in the school knew her. In fact, they called her the “campus queen.” But, on the other hand, I would say, I'm an unknown soldier.

Tadolini:

So then, you saw her at Stanford?

Peng:

So, in April 1967, when I went to Stanford, at one of the Stanford Chinese student activities, I saw her. Of course, I recognized her. I don't think she recognized me then, you know, we never communicated. I figured, oh boy, she has a lot of students after her. I didn't want to compete on that case, so I never talked to her.

27:20 A FAMED MARRIAGE AT STANFORD – FROM DRIVING LESSONS TO A PROPOSAL IN TWO WEEKS

Peng:

Very surprisingly, in about a month after, I got a call from her, and she said, "I bought a new car." And, she said, "You know how to drive? Could you teach me how to drive?" I was flattered. I accepted that coach role right away. I said, "Yeah, sure!" So, afterward, every day after school, I went to her place and escorted her and coached her in the driving. But, after two weeks, I just proposed to her.

Tadolini:

Two weeks!

Peng:

Two weeks, yeah. And, in fact, she asked me, she said, "Do you do this to every girl you meet?" I said, "No, I think it's different to you. But to me, you know, I knew you ten years, more than ten years. Yes, to you, you only knew me for two weeks.” She accepted that.

And then, when she told her father, that's where the problem started. Her father never approved. He opposed vehemently. Mainly, in the Oriental system, the family tree is very important. She is from one of the richest families in Taiwan. I am from the bottom, the poorest group. So, her father opposed very strongly, vehemently, whenever my family went to propose. But, she insisted. She never gave up. So, after a year, her father gave up and agreed we should get married. So, we were married right away.

I remember very well on June 14, 1968, at the Stanford University Church, and I say it was one of the most magnificent wedding ceremonies in the Stanford University Church history. The pastor, the presiding pastor, told us that. Felicia planned everything, and recorded it in– we used to have that wedding book with us. She planned everything, everything recorded there. So, after the school, after the wedding, we became so famous in the university. Soon after, our apartment became the center of the Chinese activity in the San Francisco Bay Area. We seldom were by ourselves because we always had visitors, but Felicia always entertained them. She was even unanimously named to preside over the China night for the Stanford University, I would say, about two months before we left Stanford.

30:47 FIRST ENGINEERING JOB – HEAD OF THE US BUREAU OF MINES TWIN CITY ROCK PHYSICS LABORATORY

Tadolini:

So, what was your first engineering job after you completed your PhD at Stanford?

Peng:

I think I finished my PhD dissertation examination in June 1970, and then in early August, I reported to work with the US Bureau of Mines Twin City Research Center in Minneapolis, Minnesota as a research engineer. At that time, I was doing a basic rock behavior study in the Rock Physics Laboratory. But, at that time, the rock physics research, mainly, or the rock mechanics research, really pertaining to – restricted the laboratory study. They mostly did some rock mass study; it really had nothing to do with mining at all.

The first thing we do there, before my time really, is to use the so-called servo-controlled testing machine for studying the rock behavior from the whole complete stress strain curve history. Actually, the MTS servo-controlled testing machine now is a standard rock testing system. Actually, at that time it was developed by the Twin City Research Center in the laboratory. So, I used that system, to develop and to conduct research. I have done a lot of research with it; I published a lot very quickly.

I guess I impressed the center director, and, within less than a year, they put me in charge of the rock physics laboratory, which is the largest group in the center. At that time, also, Dr. Charles Fairhurst was at the University of Minnesota, and of course, he was at that time – he's a big, big shot in rock mechanics. I went to visit him, and knowing him and also knowing his five, six PhD students working for him, we arranged a joint seminar with them, one week there and one week here. I learned a lot from him in terms of how to, how he promoted himself, and how he became so famous in the rock mechanic field.

34:05 WEST VIRGINIA UNIVERSITY – CIRCLING BACK TO MINING RESEARCH & TEACHING

Tadolini:

How did you end up getting the teaching position at West Virginia University?

Peng:

I guess in 1973, or 1972, several things happened that really reminded myself that my original purpose to come to the US is really doing some study to get some solutions for the Taiwan coal industry. But, after finishing the school with Felicia, I owed so much money. So, the only thing I did after I finished school, the only thing I remember is, I needed to find a job making money to repay all these loans. So, I forgot this original objective, that's why I went to Twin Cities – that's the rock research.

So, in 1973 or so, there were two events which reminded me that, well, what I came to the US for. One is, US Bureau of Mines headquarter in DC had a personnel change. Jim Scott became the assistant director of mining, and he wanted applied research; he didn't want to do fundamental research. The Twin City center happened to be purely fundamental research. So, Jim Scott forced the research director, and put a lot of pressure on the Center research staff, wanting them to implement a change right away to applied research. Since the staff was used to fundamental research, they really had a problem. The second thing that happened is, in 1972, the Arab Oil Embargo prompted US Congress to develop the so-called energy independence policy. In the policy, coal played a very strong role because of the abundance of coal in the US. So, that reminded me that, well, it's time for me to come back to, really, what I have come to the US for. And, it happened.

One evening at home, I saw a classified ad in the “Mining Engineering” monthly, the official journal of SME. It was just one- or two - line sentence. It said, “Great opportunity for mining research and teaching.” But, it didn't say anything else, just two lines. So, I sent my resume in. I forgot it completely in the morning. And then, one night, midnight, I was sleeping, and the telephone rang. So, I picked up the telephone. Well, later I learned I talked to Dr. Kelley. He's the Dean of the School of Mines at WVU (West Virginia University). He said, "Well, you have a pretty strong qualification. Would you like to come to interview?" So, he explained to me what WVU’s mining engineering program was. I said, "Okay, I'll come."

So, we set up the interview date, and I hang up, and I went back to sleep and completely forgot it. When the day came and at the same time, midnight, the telephone rang, and Dr. Kelley said, "You didn't show up for the interview." I said, "Gee," I said, "Who is this? Is it a colleague?" And, I realized that I forgot, but he was very nice. We set up another day for the interview.

38:11 WVU MINING PROGRAM CHAIRMAN FOR 28 YEARS – “WHERE MINING RESEARCH IS SUPPOSED TO BE”

Peng:

But, when I came here (Morgantown, WV), I was so impressed. It completely changed my attitude toward WVU because, if you look around the campus, it's all coal mines. Everything is surrounded by coal mines. I said, this is where mining research is supposed to be. If you do teaching and research in mining, this is where it's supposed to be. At that time, really, I had another offer from Stanford. Stanford wanted me to go back to Stanford. I said, Stanford is somewhere, I think – Stanford is in San Francisco – what for? That's not where mining is. And then, Dr. Kelley, in order to attract me more, he offered Felicia a job too, as a research engineer. Well, that's it, and Felicia said yes. She will come with me.

So, we came, July 1974, reported to the school. But, at the time, Dr. Kelley, because the school was expanding, he hired quite a few, three or four, young faculty. I would be the fourth young engineer and young faculty. But, the others, two, three faculty, always fought with him because they didn't like his management style. So, pretty soon they left.

So, pretty soon there's about five – four faculty left, including me. So, Dr. Kelley appointed me and said, "You'll be the chairman." I said, “I don't think I know how to do that." He didn't listen to me. He just said, "Send the memo out to everybody." So, I was the chairman of the mining program in January 1979. Now, I was the youngest one, and I didn't know anything about teaching. I didn't have any teaching experience back then. Besides, I was an unexperienced foreigner just beginning to learn US mining engineering education. I really wonder whether Dr. Kelley knew what he was doing.

But anyway, once I accepted this job, I worked very hard. Really, when I say I worked very hard, as a chairman, I taught two, three courses every semester and did the chairman work. I also taught two or three courses every semester and did two or three projects, research projects, at that time. So, very soon, all the senior faculty, three or more of them, I convinced them. I won them over, and that's how I stayed there 28 years as department chairman. Nobody challenged me.

PART 2

00:34 DEVELOPING THE US STANDARD FOR LONGWALL MINING & RESPIRABLE DUST RESEARCH

Tadolini:

Your professional career can be summarized into three categories: mining research and consulting worldwide, mining research and education, and support in the mining industry. Let's start with mining research and consulting. What were the principal areas you researched and consulted in?

Peng:

When I came to Morgantown with WVU, I need to say that I really didn't know anything about US coal mining, because I hadn't even seen a mine and what kind of things they used. But, as I started working on it, I grew with my research and grew the knowledge it's in. I have developed, I can say, probably roughly in two areas. One is ground control. and the other is longwall mining. Let's start with longwall mining. RA that time, the US had the energy independence program, and the purpose of the program was to increase coal production, so we could become energy independent.

Coal is one of the major players. In the coal industry, say we need to increase production. The room and pillar mining we used to have is not a good productive method. So, we imported, started importing, longwall mining from the UK, from Germany. As we started this new mining method, there were a lot of things we don't know. For instance, at that time, there was a lot of face supports with different types. Powered support was used for longwall mining in the UK and Germany. You have frames, you have the chocks, you have shields. In the shields you have four hydraulic legs, you have two hydraulic legs. All different types of supports. So, which type is better for the US? We didn't know that then.

My research in that was clearly showing that two leg shield is better for longwall mining in the US. After we published our paper, in the mid-eighties, the two-leg shield became the US standard. In fact, I think the impact was so big, the UK Institute of Mining Engineers [The North of England Institute of Mining and Mechanical Engineers] gave me an oversea award in 1992 just for that research. And, right now, the two-leg shield has become the world standard in longwall mining.

The other thing that I think impacted longwall mining very big is bidirectional cutting. When we imported the longwall mining from Europe, they came with just single, uni-directional cutting. In other words, you cut one direction of coal. In the return trip, you didn't cut, just empty running it. In the US, the coal industry thinks well, that's a waste of time; so, we should cut bi-directional cutting. But then, the UMWA [United Mine Workers of America], the union, opposed very strongly. They said, "Well, yes, bi-di cutting has increased production, but the respirable dust increases, also." Dust is hazardous to the coal miner. So, they opposed very vehemently, and so I started doing this respirable dust research.

My research on this respirable dust resulted in the final findings that the bi-directional cutting really didn't increase the respirable dust too much at all. So, the industry picked it up, and the UMWA didn't oppose anymore. So, right now, the bi-directional cutting has become a standard longwall mining technology.

05:37 THE SURFACE SUBSIDENCE PREDICTION MODEL – DAMAGE ASSESSMENT & CONTROL

Peng:

The other one we did is automation, because the powered support – I started monitoring the data, the pressure changes of the data, all that. That's really big data. Once you collect those big data, how do you develop some software? You can predict what the roof condition is and predict the hydraulic system of the shield support, all that. So, it's the beginning of the longwall automation.

So, with all this research result we have accomplished – I worked with the German manufacturer at that time it was in Westfalia. We developed a longwall mining system completely new. In 1992, we started to develop – started a design – for Cumberland Mine, Kirby, PA. The system was completed and went into production in 1995 in Cumberland Mine, and the system is really what is now the so-called world, worldwide standard, the system now.

In the ground control area, I think I probably can summarize it in two areas, one is surface subsidence and the other one is computer modeling. Surface subsidence, of course, is because of the longwall mining. Ground subsidence caused a lot of problems, including structure damage, water drainage problems, all of that. But, I started collecting subsidence data in 1977; and, up to about mid-1980s, I had collected almost about 200 sets of data. So, we developed a surface subsidence prediction model, which was calibrated with all these data, and therefore, it's very, very accurate, especially for the Northern Appalachian region for prediction of surface subsidence. And then once we knew how to predict the surface subsidence , whenever the longwall mining pass by, then we could assess what kind of damage it would do to the structure. The structures could be a house, could be the TV tower, could be an underground pipeline, gas pipeline, or anything. After we assessed the how it would be damaging to all the structures, then we also developed some kind of mitigation control measures to reduce or eliminate damages.

So, this is really a routine procedure, from subsidence prediction, damage assessment, and damage control, it's a routine procedure. We have applied this routine procedure over in this area all, probably, to more than 100 projects. So, it's been very well recognized. The state agency, like Pennsylvania, West Virginia, Ohio, Maryland, they all accept it as a routine procedure. I would say without all this, without this technique, a lot of the longwall mining in this area – which is a major US longwall mining area anyway – in this area, all this longwall mining would have a hard time.

09:46 THE FINITE ELEMENT METHOD – SOLVING GROUND CONTROL PROBLEMS WITH COMPUTER MODELING

Tadolini:

And then, you got into computer modeling?

Peng:

Computer modeling is where I use computer modeling to solve the pillar design problems, roof bolting, and mine plan, and all that. What I like is it for the stress analysis. When I was at Stanford, I got to know a PhD student in civil engineering, and his dissertation was the finite element method. Actually, he was one of the pioneers who developed the finite element method. So, we became very good friends. We stayed in the computer center together. At that time, it was still the mainframe computer and no personal computer yet. So, we stayed with the mainframe computer at the computer center very often, and we became great friends. So, I became very [familiar with] the finite element method.

So, ever since I left Stanford and started my own research, I always use finite element method for mine structure stress analysis from the NASTRAN in the 1960s all the way up in the 21st century, the ABAQUS program. But, the problem with the numerical modeling is that mine structure is big. You've got to be – like a longwall panel is what, 1000-1500 feet wide. You see that is very big, it's a lot of computer memory required, and, also, it needs to run very fast. The computer technology, its development, to us, is very slow. So, the computer modeling technology for ground control is following the advancement of the computer technology. When I say computer technology, it's memory size and processing speed. The computer technology didn't develop until early 2000, I say, when we could comfortably apply the computer technology to solve ground control problems. I think I mentioned before, the ground control problem; I used computer modeling for pillar design, roof bolting, entry stability and mine planning, all that, too.

Tadolini:

And, you've got an incredible breadth of publications that document this work and everybody's using them to this day.

Peng:

In terms of my publications, in my career, in my 30-some year career, I think probably more than 380 journal papers. I have also published 12 books. One thing I'd like to say is, all those papers I published, I published them in different types of journals and amid different types of audiences. So, the technology, or the result we get from our research, we publish it really to make it known to a whole spectrum of the industry people. It's not, say, only the engineers that know it, because the operation people also know it. So, I would say, because of that, my research is very well known to the coal industry, especially.

14:01 FOUNDING THE INTERNATIONAL CONFERENCE ON GROUND CONTROL IN MINING

Tadolini:

That leads naturally into the ground control conference. Of course, one of your greatest accomplishments, in my mind, was the creation and nurturing of the International Conference on Ground Control in Mining [ICGCM]. This is how we met. You probably don't remember me in 1986 when I attended my first conference. This helped me decide to focus on ground control research. Why did you start that conference, and what have you been doing with these incredible outcomes?

Peng:

After I came to WVU in Morgantown, I started the mining research. And, I went up and down the Appalachian coalfield a lot and went to a lot of coal mines. Because in my approach, the research approach is that I use the mine as my laboratory. So, I met a lot of the mine people. A lot of the mine people, they don't know that many ground control technologies were, well, available; and among some who know, they were saying, "Oh, that's not realistic. and “It was developed by a researcher, university professor.” Some of the professors, they wrote all these papers, they didn't understand it, and some of it is not realistic. Then, I also found out that the mines used a lot of equipment and the manufacturer developed all this new equipment; and before they can be used or they can sell it, the MSHA [Mine Safety and Health Administration] needs to approve it. I also realized that the mine engineers, once they developed and implemented a mine layout/method, if they want to change it, introducing a new technology, MSHA also needed to approve it. So, I figure all these people really need to get together to talk about it. Otherwise, they all individually are isolated. That's the reason I started it in 1981, this ground control conference.

It has been 40 years now, and I think we have accomplished a lot; and, we have dealt with all different types of problems: legal problems, technical problems – technical like geology, geophysics, civil engineering structures, computer science, all of that computer modeling. All different type of aspects of the ground control issues, we have dealt with it. The most important one, I think, if there are any new technologies introduced or presented at the conference because we have so many mine operators attending it, they would pick it up right away and get back to the mine and try it out. If the test run is good, they will continue, and it will become the industry presiding technology. If it's not good, well, it would be rejected right away. So, I think that's really the essence of the equipment development and application. I think it's unique in terms of the conference. I don't think any conference can match that in their category.

17:41 ICGCM 40TH YEAR – ACCOMPLISHMENTS & PROUD MOMENTS

Peng:

And also, I like to say that it has been 40 years now, and we have just reviewed those papers from 1981 to 2020. There are about 1795 papers published there and peer reviewed there, with more than 9000 attendees from all minerals producing states of the US and from about 42-43 countries over here. So, really, I have achieved the original goal of getting all these people together, getting all the different stakeholder-related associates with the industry together to discuss the problems in any fashion.

Tadolini:

As you know, I probably attended 30 of those conferences, and I made relationships that not only helped me in my career, but it, just, it's unbelievable how you can pick up a phone between industry manufacturers, professors, consultants, and then you can collaborate. And, that's what I think has been so important about that conference.

Peng:

Yes.

Tadolini:

One of my most – one of the most thoughtful comments that I've ever heard at the conference was in the 25th anniversary. Remember, we had the big celebration up at Lakeview, and David Dye, Acting Director of US Mine Health and Safety Administration, was our guest speaker at that conference. And, he said he would "like to recognize Dr. Peng for his significant contributions in longwall mining and ground control. His contributions have had a major impact on improving safety and reducing fatalities in America's mines. Thank you, Dr. Peng, for the important work you have carried on throughout the years. Many miners are alive today because of your dedicated work to protect them." I still remember that quote. It was spot on, and the reason that you've worked tirelessly to make mines safer and more productive. So, thank you, Dr. Peng.

19:46 EDUCATION & TRAINING OF MINING ENGINEERS – DEVELOPING THE PHD MINING PROGRAM AT WVU

Tadolini:

The education and training of mining engineers is such a significant part of your career. Can you tell us a little bit about your experience at WVU?

Peng:

As I say, I was appointed chairman of the mining engineering department in January 1979. I really had to start at zero all over again, but I figured, at that time, WVU mining engineering program started in 1868 and the undergraduate students, undergraduate program is, I think, very strong. I don't need to tinker with that. And, the evidence is in all the major coal companies, big or small, WVU alumni are occupying all the top management positions. So, the undergraduate is strong. I think, at that time, I think all I needed to do, really, is to increase the visibility of the program. Now, in order to increase the visibility of program, I thought I have to develop the research program. And, to develop the research program, I have to develop the PhD program.

So, I started the PhD program as soon as I became the Chair, and I got that program approved to offer it officially from the state of West Virginia in, I think, in 1986. So, during the 28 years of my chairmanship, there was, I think, 65 PhD graduates, more than a thousand BS and MS graduates, and they spread all over the US coal industry and all the major coal industries in the world, too. So, the PhD program became strong in the sense that it published so many quality papers. So, it made the program very well-known from, obviously, an unknown program before my time to a world-renowned mining engineering program. In the program, I like to mention, that I improved the program almost about – the curriculum, I would say – over eight times. Whenever the industry has a new thing come up or a new feature come out, I would try to incorporate it into the program, into the curriculum. So, I made that eight time change, as I remember. And, I also, during the 28 years, maintained the ABET accreditation.

23:01 ENDOWMENTS & FELLOWSHIPS – ESTABLISHING THE COAL & ENERGY RESEARCH BUREAU

Peng:

Funding-wise, you know, the school funding-wise, I think I did a lot. The school, the mining engineering program, became the most endowed department at WVU because of the following programs. Let me mention, but first, I work with the industry, work with the alumni. We convinced the state legislature to appropriate, in 1998 or '97, to establish the Coal Research Bureau [Coal and Energy Research Bureau, state of West Virginia]. So, every year, they allocated $300,000 to us, and that's the gold mine coming to the mining engineering department. And, I used that $300,000 money by dividing it into all– every faculty has a project, at least, has seed money for their research.

In 2005, I figured, I think I need to step down. So, I worked with the industry and the alumni, we got a line-item budget from the state legislature, about $700,000. I used that money to hire a new chairman to replace me. I stepped down as the Lawall Chair Emeritus. I also worked with the industry to get three endowed chairs, endowed professorships, like the Massey Foundation, get the Massey professorship. I also worked with CONSOL to get the Lawall Chair, to which I was assigned when I stepped down as department chair. Then I also dedicated, myself, Felicia and I, the Syd and Felicia Peng Professorship.

25:25 RESEARCH ABROAD – BRINGING THE GROUND CONTROL CONFERENCE MODEL TO EVERY SCHOOL IN CHINA

Tadolini:

Excellent. But, the education of mining engineers is not limited to WVU. You have also made a tremendous impact in China as a special professor for Henan Polytechnic University in 2010 and China University of Mining and Technology in 2013. How did this opportunity come about? Exactly what were you trying to accomplish?

Peng:

In my career, I handled a lot of projects at WVU for mining research. But, there's a lot of, also, fundamental issues or some more difficult applied research issues that I couldn't do. It's unresolved because of the money situation, funding situation, because of the manpower situation. So, I figured out, you know, looking at the Chinese coal industry, they have 2 million people involved in the industry. There are so many technical people involved. So, I figured all these issues, I probably can go to China to try to get it solved there because they have the funding, they have the manpower. So, that's why, I think in 2010, after I stepped down finishing my book writing, then I started going to China every summer. Probably it was sometime one-two weeks a year. In the beginning, the maximum over one year or two years, I stayed for three months.

I supervised research projects and guided the young faculty and graduate students for research. Of course, I also lectured a lot about what I have done in the US, about ground control, longwall mining in different schools. Then, after all these years, I also found the ICGCM-China, the ground control conference, the model we used here, they could use it. Really, they could use it because the safety record is so bad that they could use our model to reduce it. So, in 2014, I started this ground control conference. So, it's been this year it will be the eighth time now rotating in every Chinese coal mining school. They have that now.

28:12 TRAINING CHINA’S COAL INDUSTRY LEADERS & IMPROVING CHINA’S SAFETY RECORDS

Peng:

I also would like to mention two more things. In the early 1990s, the Chinese Ministry of Coal Industry started sending, I think -- once they learned the US longwall mining technology is so good -- they started sending delegations. I think it totaled about 25 delegations with more than 400 top management persons in their coal bureaus, because they have about 30 some coal bureaus all over in China. They sent them over to WVU for the program they call, the high production, high efficiency, and mine safety training program. I lectured them and also took them around to see the longwall mines.

I found out this year, when I went back, a lot of the mine techniques they use now are US technology; and I'm pretty sure it was all during this time, my training of all those 400 some management persons. For example, like an entry, like the underground opening entry, it used to be an arch type of support, but now they use the same thing; rectangular opening, in-the-seam mining, and roof bolting. I was told about 80-90% of coal mines are using these techniques now; and, if you look at the longwall mining equipment set up or panel layout, it's exactly the same as we have here. So, I think the inference there is very obvious in that, you know, but nobody really is going to say that openly. But, I would say, after all these years that I've been there, I found out that was the truth.

Tadolini:

And, they also established an MSHA like agency, I think that was so important.

Peng:

That's right in, I think in 1998, me and my colleague, we wrote a letter to then Chinese Prime Minister, Zou Rongi. I said, "Your coal mine accident fatality is so bad. You could use an MSHA, like our MSHA administration, agency like that." They accepted it right away, at that time. In two weeks, I got a reply saying, "Yes, we will do it." If you look at it now, some 20 years later, you look at their fatality, injury, safety record now – of course, compared to US, it is still bad. But, compared to their whole history, it’s more than 1000 times of improvement there, because of the agency set up.

31:34 SOLVING PROBLEMS FOR INDUSTRY – EXPERT CONSULTANT IN GROUND CONTROL

Tadolini:

Excellent. In addition to everything you were doing at WVU, you're also recognized as an expert consultant in the area of ground control. Something that you even continue to this day. How did that come about?

Peng:

I think the consulting, as I reflect, is because of my research. I emphasize theory and practice, and so, my publication has a lot of case histories in it. So, I think the industry became knowing me well, that I can solve the problems, and indeed I do solve the problems. So, over my career, I would say, as I remember, I must have consulted almost 240 some projects with about 170 clients. I have to say there's always a consulting job. There's always a good client who came to me for help, and so on. There's quite a few I like to mention that're very, very significant to me, and I achieved respect, you know. There are two cases of expert witnesses that I did. One is in Indiana there. The mine closed, was closed because of a subsidence issue, closed for almost a month. So, 300-400 of the mine people lost jobs, no pay. So, they hired me to defend because there's a lawyer – the other side was from Washington, D.C., an environmental lawyer, shut them down. So, I defended it, was successful, and with my defense the mine reopened and recovered. They started back to work again.

The other one I remember very well is an undersea mining in Cape Breton Island, Nova Scotia, Canada. The miners, UMWA members too, refused to work because they found the longwall mine panel in the gob had water flowing around. They said, well, it must be the ocean leaking down. They didn't want to go back to work again.

So, in the city of Sydney, it has 2000 miners in the mine, in that mine. They all went out of work, you know, so the mine, the city become very affected. Then they hired me, I remember it was the Labor Day and they called me, and they said, “I want you to come right away to solve the problem.” So, I went there. I assessed it. I told them the water is not from the ocean above the mine. It's because of the “cognate water” in the rock ... I forget how the terminology is used.

"It is the sandstone water in the roof," I said, and the mine said, "Well, okay. If you say it's not the ocean water, would you defend it in front of the UMWA members?" I said, "Certainly, I would." I was there in the meeting for almost two hours – the UMWA members asked this question and that question, and all that. Afterward, they were convinced, and they went back to work the next week. So, 2000 people got back to work, and they saw the city of Sydney revive again. I asked a UMWA officer member, I said, "Why did you believe me?" He said, "Well, before you came, we checked around and know you. We found out you are reliable. You're a believable one. "

36:12 MY CAREER AWARDS & ESTABLISHING THE PENG GROUND CONTROL IN MINING AWARD

Tadolini:

Straight shooter. That's what you need in this business. You've also received several awards for your research and academic achievements. Can you tell us about some of those?

Peng:

Yeah, in my career, I think, in total, big or small, I received about 21 awards and from different type of organizations and worldwide, really. I think in the 80s, I got the SME Rock Mechanics award, and then, in the early 1990s, as I may have mentioned, in 1992, I got the UK's Institute of Mining Engineers Oversea award. In early 2000, I got AIME's Erskine Ramsay Medal. And then, 2003,2004, 2005 -- three years consecutively – that's also a big one too: I got this, US R&D Top 100 Award from the R&D Magazine. In 2006, I was inducted into the National Academy of Engineering, and this year, (2022), I will be inducted into the National Mining Hall of Fame and Museum.

Tadolini:

To help support the ground control mining discipline, you and Felicia established an endowment at SME. The Syd S. and Felicia F. Peng Ground Control in Mining Award. This endowment recognizes individual accomplishments in ground control but, more importantly, has provided several graduate and undergraduate scholarships every year. Why did you and Felicia establish this endowment?

Peng:

Well, in spite of my whole career's work on ground control, I think there's still a lot of unresolved issues that need to be done. Of course, we have accomplished a lot of it, and I'm pretty sure the technologies of this area will continue to develop. But, in order to give the future of ground control a boost for the effort we, Felicia and I, decided to set up the ground control award with the SME Foundation to recognize those who have contributed to the field of ground control or the science of ground control. So, I believe we set it up in 2005, the first award was given in 2006.

So, up to this year, we have 17 awards we've given to recipients from US, Australia, and China. And also, I think Felicia and I also felt that there's a potential shortage of ground control engineers because we heard the industry has had a difficult time hiring the ground control engineers. So, we set up a set of scholarships with the SME Foundation to encourage the future graduate students or undergraduate students who would be interested in ground control and engage in ground control research so this field will continue in the future.

[So far, for the SME scholarship, more than 40 scholarships have been awarded to students from all 13 US mining engineering programs and one Canadian mining program. Each scholarship ran between US $4000-5000. Eight scholarships will be given this year.]

40:33 A GLOBAL LEADER ADVANCING THE SCIENCE OF GROUND CONTROL

Tadolini:

Yeah, it's a very large scholarship, too. Well, Professor Peng, you've been a global leader in the ground control discipline. What is the next puzzle piece or pieces of this complex topic that are needed to be understood, and how do we get there?

Peng:

I think for the past 40 years we have published a lot, and all these accomplishments have been shared with the stakeholders. But, if you're looking back, reading the conference papers, more emphasized applied research type and solved the mining industry operational problems. And, I think this will, because momentum is there, I think this area will continue to develop. But, I think what we need really to do is the fundamental issues. A lot of this applied research has to be based on the results of fundamental research, and that (applied research) was what I think we had done for the past 40 years. And, that the area of fundamental research we need to emphasize in the future, solving the fundamental issues, so we can advance the science of ground control.

41:59 IMPACT ON THE MINING INDUSTRY – ESTABLISHING GROUND CONTROL AS A MAJOR DISCIPLINE IN MINING

Tadolini:

With so many achievements, what do you think has been your greatest impact on the mining industry?

Peng:

I think, I have, in terms of the impact, I think of nationally or globally, it is in two areas. One is ground control. The other is longwall mining. In terms of ground control, I think for ground control, we have established it as a major discipline in the mining operation. It's also been recognized that ground control can solve the problems. A lot of the unsuccessful issues with mining, without ground control, would never have been resolved.

The other one is the ICGCM, this ground control conference. I think we have convinced people that all the stakeholders had to come together – networking together – and so, all this solution you develop or research, would be multiple disciplinary. And, it would not be an ivory table type of solution, and I think that's important. And, this is in the ground control area.

In the longwall mining, and I think as I mentioned, in the three major systems – power support, shield, and in the automation part of it – we have done so much, we have contributed so much. I think we really are the major contributor to what the US longwall mining is in terms of safety, in terms of high production, and that the US longwall system has become the world standard now.

Now, the third area like this is more parochialism for West Virginia. That's the management of the mining engineering program. West Virginia is an energy state. So mining gets a lot of funding and it’s easier to get funds. So, in a state like West Virginia, mining engineering is small compared to other engineering programs like computer, chemical, mechanical, all that. So, how do you survive a small program in a large department? I think that has a lot to do with, for my 28 years of chairmanship, that's really what I have learned. How to survive a small program in a big unit.

45:22 CONCLUDING REMARKS – INFLUENCING FUTURE GENERATIONS OF MINING ENGINEERS

Tadolini:

Professor Peng, what an honor and pleasure it has been to spend this time with you. You have an incredible story and a career that has truly changed the mining industry. You and Felicia, through generous donations, will ensure a full pipeline of qualified ground control engineers for generations to come. And, if people are interested in learning more about your journey, they can obtain a copy of your autobiography "An American Dream," available at the SME Annual Conference. The read was inspirational to me. Thank you so much again for your willingness to share your story with AIME.

Peng:

Thank you, Steve.