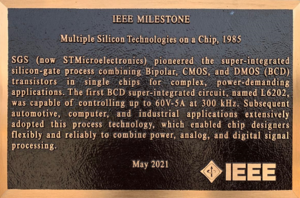

Milestones:Multiple Technologies on a Chip, 1985

Title

Multiple Silicon Technologies on a Chip, 1985

Citation

SGS (now STMicroelectronics) pioneered the super-integrated silicon-gate process combining Bipolar, CMOS, and DMOS (BCD) transistors in single chips for complex, power-demanding applications. The first BCD super-integrated circuit, named L6202, was capable of controlling up to 60V-5A at 300 kHz. Subsequent automotive, computer, and industrial applications extensively adopted this process technology, which enabled chip designers flexibly and reliably to combine power, analog, and digital signal processing.

To view dedication ceremony, please click here.

Street address(es) and GPS coordinates of the Milestone Plaque Sites

- Site 1: STMicroelectronics Srl, Via Camillo Olivetti 2, 20864 Agrate Brianza, Italy (GPS: 45.571066, 9.363077)

- Site 2: STMicroelectronics Srl, Via Tolomeo 1, Cornaredo, Milan, Italy (GPS: 45.470882, 9.034128)

Details of the physical location of the plaque

- Site 1: Outside the main entrance near ST security, but visitors do not need a security escort to see the plaque. The site is where ST started its business over 55 years before this Milestone was dedicated. As shown in Figure 1, it is close to Milan and the Linate Airport.

- Site 2: Mounted on a plinth outside the main entrance near ST security, but visitors do not need a security escort to see the plaque.

How the plaque site is protected/secured

- Site 1: Security guards and a camera, 24/7 access.

- Site 2: Security guards and a camera, 24/7 access.

Historical significance of the work

Summary of objectives and vision

Key objectives, that motivated STMicroelectronics (short name ST) Silicon Gate Multipower BCD technology development on early 80’s and onward, were:

1) To create a technology integrating heterogeneous transistors and diodes capable to deliver electric power in the range of hundreds Watts

2) To control such a power with logic, which implementation would scale with Moore law

3) To minimize power consumption thus removing heat-sinks

4) To support precise analog functions

5) To address a broad range of applications with reliable implementations

Summary of achievements

To meet such challenging objectives and long-term technology vision, ST since 1985 developed

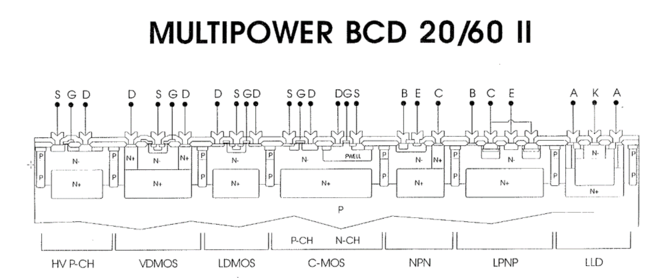

1) A new integrated Silicon Gate Multipower BCD [1,2,4,9], that allowed the integration on a single chip of diodes, bipolar linear, complex CMOS logic, and multiple DMOS power functions with complex interconnections. The architecture of the process was chosen to optimize the power part, which generally occupied the most chip area. With the DMOS device, many other signal components have been obtained whose electrical and structural characteristics were in relation to manufacturing process.

2) The first proof was the integrated chip, L6202 operated at 60V, delivering 1.5A, switching power at 300KHz with a complex topology connecting power MOS in a package without heatsink [2, 3, 4, 8, 10, 11, 16, 18 pag 571 12/1986].

3) ST has sold more than 30B devices using ST Silicon Gate Multipower BCD [Slide 29 in ref 17 and ref 15]

Besides, the following characteristics have been achieved in the developed technology:

4) To use very efficient silicon gate isolated power DMOS transistors, having all contacts in the top surface and in place of bipolar power transistors. That gave the freedom to integrate higher number of DMOS transistors connected without constraints in a compact chip [4]. Moreover, Power DMOS shown no driving power in dc condition, and no secondary breakdown limitation.

5) Compatibility with CMOS silicon gate devices, enabling very fast switching speed [1, 4]

6) Integration of complex CMOS logic up to complexity of modern micro controllers following Moore Law (figure 6), (figure 11, [4])

7) Use of DMOS component as Power device secure hundreds output power without high dissipation overcoming high current heating that were obstacles to the miniaturization of power switching [4].

8) Reduced electromagnetic interference and better device reliability

9) Technology modularity by allowing to add further Non-Volatile Memory, Insulation, Galvanic isolation, extended power range to KVs

10) Thanks to the integration of power management, data conversion, processing and actuation functionalities many diversified applications were addressed, such as automotive [20] (engine management, ABS, airbag, ESP, car radio, vehicle electrification, charging stations), computer peripherals (printers, hard drives, wireless charges), phones, micro machines MEMs, bio-medical (ultrasound imaging, echography), consumer, industrial (lighting, displays, powerline modems) etc

Existing implementations

Power ICs were realized by using pure bipolar technologies for the audio amplifier market. These devices, mainly operating in switching mode, were severely limited by the poor efficiency and the thermal run-away effect of bipolar power transistors. This poor efficiency meant that a significant amount of power was dissipated inside the device. Since there was a limited dissipation capacity of an IC package, this represented a limitation on the available delivered power.

Another limitation was the poor density of bipolar logic: with the growing request of logic functions, the I2L approach was no more competitive due to its design complexity, high power consumption and limited shrink capability with the lithography.

Other processes used discrete-type DMOS structures where the lower surface of the die was the drain contact, so that two or more DMOS devices could only be placed on the same chip with the limitation constraint to have a common drain contact. Existing configurations were not feasible for complex connections and numerous power device integration, since featured drain on the bottom of the die where a single or common drain power transistors can be integrated [5]. This limited the freedom to design complex integrated BCD circuits. In [6] the core of the fabrication sequence was a metal gate CMOS process. Using that process, figure 3(b) of [6] shows the photomicrograph of a test chip which complexity was very simple. Other firms were focused on metal gate standard CMOS to which added Power MOS and bipolar. This was another key difference vs ST Silicon Gate power DMOS which was integration friendly with standard CMOS, bipolar transistors and diodes. As matter of fact Silicon Gate Multipower BCD introduced by ST become broadly adopted by many applications pushing the former to niche application. If the former would be used broadly then it couldn’t scale, couldn’t be cheap like the ST technology thus preventing it to be adopted into a broad range of applications like ST technology achieved. Those solutions, with Metal gate Power MOS architecture presented in the early phase of BCD technology had short life and disappeared up to the point today they are no more used and not being compatible with CMOS silicon gate evolution.

ST innovations

ST innovated combining on 1984 DMOS/CMOS/Bipolar/Diodes technologies [2]. Silicon Gate Multipower DMOS devices were the best way to manage high power in a monolithic system: in fact, they exhibited technological compatibility with silicon gate CMOS, very fast switching speed, no driving power in dc condition and no secondary breakdown limitation. Since DMOS power stage had intrinsic recirculation diode, no external discrete diodes were needed, saving components [1,2,4,9]. Technology compatibility with Silicon Gate CMOS secured very high-density signal circuits. At the same time high precision analog performance were provided integrating bipolar transistors.

This technology allowed the integration on the same chip of more power DMOS devices isolated from each other, together with Silicon gate CMOS and Bipolar transistors (fig.2), having all the contacts on the top surface. With ST Silicon gate Multipower BCD, hardware designers were free for the first time to integrate any number of DMOS power transistors connected in any way including bridge configurations as said in [4]. Differently to metal gate, ST chose self-aligning silicon gate to achieve logic scaling with Moore law. As result ST first implementation L6202 shown in figure 6 [1], figure 2 in [4], figure 4 in [8] was more complex and sophisticated vs the existing in figure 3(b) in [6].

Figure 2 Notice combined vertical DMOS and junction isolated technologies.

Since DMOS transistors are fully isolated and have all contacts on the top surface any kind of power stage can be integrated

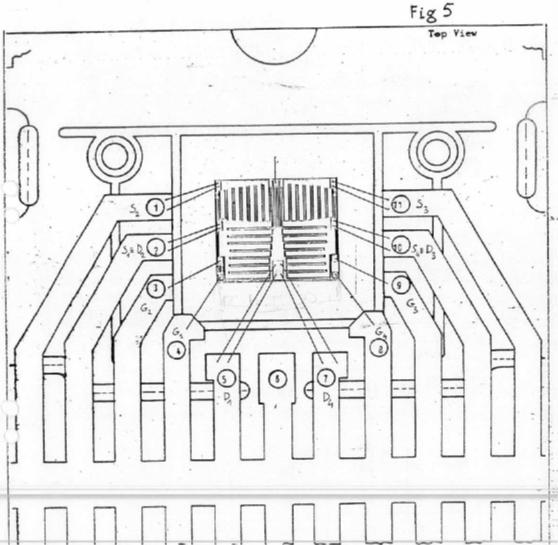

At the same time ST worked on proving the technology with hardware implementations. On 1984 the first power MOS chip has been developed and was reliably working in the range of 60V, with four Power DMOS connected in H bridge configuration (Fig.3 project code name was B4309, see internal report [7] and [2]).

Fig.3 four Isolated 60V H Bridge Power DMOS integrated in a single chip

Next on 1985 [1, 3, 8, 9, 10, 11, 16] ST, developed the first integrated circuit: a switching bridge control system for DC and stepping motors (60V, 5A) working at 300KHz with high efficiency. It used Silicon gate Multipower BCD technology just created. The powerful, monolithic integrated circuit was named L6202, internal code name U002 (figure 4). Since the power dissipation was only 1.5W when the output current was 1.5A, the device was working at this level in a standard D.I.P. package with great advantages in terms of cost (no heatsink) and compactness.

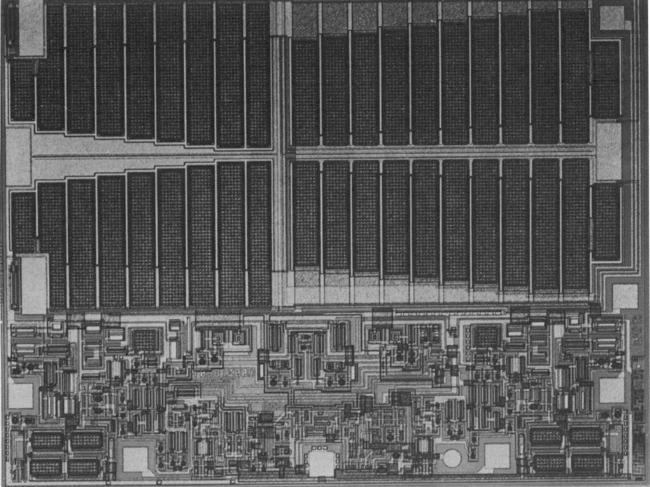

Figure 4 L6202, internal code name U002, die photograph

At the same time ST designed for comparison a bipolar bridge with identical power performances [4]. Both chips operated on 48V supplies and delivered 1.5A continuous output current. But while L6202 was assembled in a DIP package and needed no heatsink, its bipolar counterpart needed a power package and a hefty heatsink. Eliminating this heatsink by L6202 was a great demonstration of the importance of reduced dissipation in power ICs. Patent was also granted [ref. Patents 1, US 4,949,142].

This IC is still in production today, same name, after 35 years as well as many its derivatives [12].

On 1987 ST Silicon gate Multipower BCD technology was chosen by a top Car parts manufacturer [20] to address ICs for Automotive applications in the field of Power Train, Safety and Body. This cooperation is still running after 33+ years [13, 14]

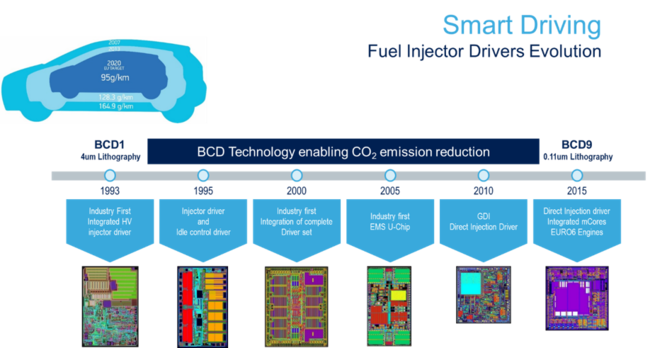

Figure 5 BCD evolution 1993 to 2015 for automotive reduced emissions

The ST Silicon gate multipower BCD integrated process secured compatibility with CMOS evolution according to Moore law giving, till today, the possibility to realize complex Smart Power systems integrating far more complex microprocessors, Non-Volatile Memories (NVM), and precise analog function (figure 5, 6).

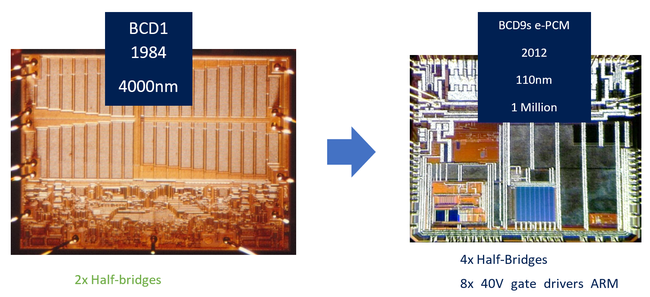

Figure 6 : Motor Control evolution: from the simplest architecture (1 Full bridge in BCD1, left side) to the Full system integration (2 Full bridges, 6 external Power drivers, ARM micro controller CortexM4 with 32 Kbytes NVM based on PCM, phase change memories, right side) in a smaller silicon area

All along the years Silicon gate Multipower BCD technology has confirmed its flexibility to differentiation, voltage capability extended up to 1200V, compatibility with various solutions of NVM, precise passive components (Thin Film Resistor, etc.) and recently even integration of Galvanic isolation (6KV) That has widened the application fields: industrial, cellular, car electrification, many others. with more than 30B units delivered on the market by ST [15]

ST Silicon gate multipower BCD technology guaranteed 30+ manufacturing life of products, and longer life of otherwise obsolete 6” and 8” CMOS fabs. Currently ST is building 12” modern fab to sustain evolution. All those fabs created strong social and labor impact on many employees and relative family’s lives with a sustainable environmental impact.

Features that set this work apart from similar achievements

The ST innovation, which has been outlined in this IEEE Milestone proposal and which has significantly advanced the technologies available at that time, can be concisely summarized as follows:

1) The very 1st silicon gate integration of DMOS/CMOS/Bipolar/Diodes on 1984, [2]

2) First proof with L6202 more sophisticated than existing therefore setting the state of art on 1985. [3]

3) Free connectivity of power MOS for the first time [1, 4]

4) High power management with low dissipation and high efficiency [1]

5) Self-aligning silicon gate Power DMOS to secure compatibility with CMOS logic scaling with Moore law, thus allowing micro controllers integration. [1]

6) Modular and scalable technology platform approach open to integrate nonvolatile memories to address diversified applications [1, 4]

7) Very fast switching speed, no driving power in dc condition and no secondary breakdown limitation. [1, 4, 7, 8, 9, 10]

8) No external components needed to achieve low cost and broad adoption [1, 4]

9) High precision analog performance [1]

Significant references

Publications: Articles, Journals

[1] A New Integrated Silicon Gate Technology Combining Bipolar Linear, CMOS Logic, and DMOS Power Parts A. Andreini, Claudio Contiero and Paola Galbiati, IEEE Transactions on Electron Devices, Vol ED-33, No. 12, December 1986

[2] Single Chip Carries three technologies, Electronics week, ISSN07 48-3252, 1984

[3] Baulemente, Drei Technologien auf einem Chip, Carlo Cini, Claudio Contiero, Petr Hrassky, Elektronik 9/3.5.1985

[4] Mixed Bipolar-Cmos-Dmos Smart Power IC Technology, C. Cini SGS-THOMSON, invited paper 21st International Conference on Microelectronics, MIEL’93; 29th Symposium on Device and Materials, SD’93; Sept 29 – Oct 1, 1993, Bled, Slovenia

[5] Integrated circuits for the control of high power; R.S. Wrathall, D. Tam, L. Terry, S. P. Robb, Motorola

[6] An Analog Technology Integrates BipolarC, MOS, and High-Voltage DMOS Transistors, S. Krishna, J.Kuo, I.S. Gaeta, IEEE TRANSACTIONS ON ELECTKON DEVICES, VOL. ED-31, NO. 1, JANUARY 1984

[7] Technical report No. 01/84, Descrizione Quartina di Power MOS Integrati in configurazione circuitale a Ponte, Agrate March, 21st 1984, C. Contiero, P. Galbiati

[8] A new Bipolar C-MOS, D-MOS, Mixed technology for Intelligent Power Applications, C. Cini, C. Contiero, C. Diazzi, P. Galbiati, D. Rossi, ESSDERC, 1985 Proceedings, Aachen (Germany), September 1985

[9] A New High Frequency, High Efficiency, Mixed Technology Motor Driver I.C., C. Cini ; C. Diazzi ; D. Rossi, ESSCIRC '86: Twelfth European Solid-State Circuits Conference

[10] The Elmer A. Sperry Award to Bruno Murari, 2017

[11] Shortform Semiconductor Products, SGS 1987 with L6202 mention

[12] https://www.st.com/en/motor-drivers/l6202.html ; https://www.st.com/en/motor-drivers/brushed-dc-motor-drivers.html#products

[13] https://investors.st.com/news-releases/news-release-details/stmicroelectronics-licenses-leading-edge-smart-power-process

[14] https://www.eetimes.com/st-bosch-sign-licensing-agreement/#

[15] https://youtu.be/v_z4TO-drag

[16] L6202 SGS Advance Data, 1986

[17] https://investors.st.com/static-files/ba419430-422e-4e99-bb66-38f61ba8e3f3, ref17_Q4 2017 Earnings Release Presentation.pdf

[18] SGS_Motion_Control_Application_Manual, 1987 (L6202 advance data pag 571 12/1986) http://www.bitsavers.org/components/sgs/_dataBooks/1987_SGS_Motion_Control_Application_Manual.pdf

[19] https://investors.st.com/static-files/ba419430-422e-4e99-bb66-38f61ba8e3f3

[20] Bosch Endorsement of STM/BCD technology application for IEEE History Center Milestone Award 2020

Patents:

1. Integrated N-Channel power MOS Bridge Circuit, US4949142A

Supporting materials

1st patent was INTEGRATED N-CHANNEL POWER MOS BRIDGE CIRCUIT Number 4,949,142 Foreign Application Priority Data

Dec. 18, 1984 (IT) Italy. 24.126 A/84