First-Hand:The First Quartz Wrist Watch

Contributed by: Armin H. Frei, LSMFormer Research Staff Member Centre Electronique Horloger

Introduction

In July 1967, somewhat more than 40 years ago, the world's first quartz wrist watch had been created by a group of researchers at the Centre Electronique Horloger in Neuchâtel, Switzerland, assembled and successfully tested for proper operation. The watch baptized Beta 1 with the identification number CEH-1020 was fully meeting the regulatory requirements concerning men's wrist watches as postulated by the established Observatory of Neuchâtel and its famous yearly "Concours Chronométrique".

In view of the fact that the history of the invention of the quartz wrist watch has been extensively neglected and/or mistreated in the past causing misunderstandings and confusion I have investigated on "Who contributed what, at what time and what was the relevance of this contribution" restricted to the event of the creation of the world's first quartz wrist watch.

Centre Electronique Horloger (CEH), Neuchâtel

Foundation

The foundation of Centre Electronique Horloger (CEH) in 1962 was a consequence of the growing threat due to the appearance of certain kinds of wrist watches in the late 50'ies which were powered by small batteries rather then by the usual springs. Such watches had been announced by Lip (France), Hamilton (USA) and Ebauches SA (Switzerland). The introduction of Max Hetzel's Accutron, the famous tuning fork watch (picture) in 1960, accelerated this process remarkably. Hetzel was a Swiss engineer, who started his investigations with Bulova in Bienne, Switzerland and later on was transferred to U.S. to direct the production of the Accutron watch. The fear to lose leading positions on the international market assembled the Swiss watchmakers under the leadership of Ebauches SA and the Swiss Horological Federation (FH) to join in a common joint stock company called CEH. The goal was simply to invent anything which was superior in at least one count of what was available on the market. This to improve the Swiss position in possible licence negociations, a rather poor vision indeed. Luckily, they found Roger Wellinger, a U.S. bound Swiss engineer, teacher and researcher, for the challenging job to create a new research laboratory in a field which was not common at all in Switzerland. Wellinger had courage, enthusiasm and farsightedness.

Goal and Strategy

The goal set up by the Swiss watch industry was to develop electronic wrist watches with at least one advantage compared to existing products (e.g. Accutron). A fairly modest goal indeed, reflecting business and legal aspects predominantly. - The strategy to reach that goal had been set up by Roger Wellinger and consisted mainly of three elements: i) recruiting and hiring Swiss scientists, who had spent a certain time in the U.S. and were willing to come back with the intention of importing technical and scientific know-how from the U.S. to Switzerland, especially in the area of semiconductors and circuits and ii) investigating all kinds of possible subsystems and later on developing new kinds of solutions similar to the morphology developed by Prof. Fritz Zwicky, Caltec. Especially in the area of acoustic resonators, frequency dividers and displays there had been a great number of various investigations resulting in a fairly complete catalogue of possibilities and iii) building up semiconductor expertise in Switzerland. – However, none of the projects until 1965 incorporated a quartz wrist watch.[1] There was neither a strategy nor a project addressing a high frequency, say 10 kHz quartz wrist watch, simply because such an enterprise was considered impossible by experts and industry leaders due to the high frequencies involved and for other reasons.[2] Even worse, in 1966, when the quartz wrist watch project was already established, the president of the governing board informed the two initiators of the quartz wrist watch project that the Swiss watch industry was not interested in this new kind of a quartz wrist watch!Since the very beginning Roger Wellinger recognized the importance of an own semiconductor laboratory. That was the only way to become independent from foreign suppliers and at the same time allowed to investigate into dedicated research. Kurt Hübner and his group started quickly and very successfully developing integrated circuits (IC) capability and competence in bipolar transistor technology and double diffused, high impedance resistors. With this it was already possible in 1965 to produce the first complex IC's. CEH was certainly in a favoured position as compared to Seiko, which equipped their first quartz wrist watch calibre 1967 with discrete transistors, resistors and capacitors, about 200 of them. – Unfortunately, since Spring 1965 the CEH and its management had been confronted for more then a full year with the CISSA project. CISSA stands for "Communauté Industrielle Suisse SA", a consortium of a number of Swiss firms together with Philips, Netherlands. The purpose of this was an unfriendly buy-out of CEH's successful semiconductor department. It was above all Roger Wellinger who fought against this fatal attempts and provided for continuous fruitful cooperation between the semiconductor department and the rest of the laboratory.

New Strategy: Montre-bracelet à Quartz

Status

The strategy and plan in the field of electronic wrist watches for the year 1965[3] concentrated on two topics: i) the Alpha calibre, a wrist watch incorporating a figure 8-shaped metallic resonator with reduced gravitational disturbances by Heinz Waldburger, otherwise similar to the Accutron and ii) the Beta project incorporating a metallic tuning fork like the Accutron, but newly with a small chain of frequency dividers to drive a separate motor. The Beta project at that time was the only one incorporating two electro mechanical transducers, the second transducer being an electro magnetic or a piezoelectric vibrating motor. The Beta project by Max Forrer was the most elaborate project concerning time and resources and further was the only one which never reached the status of a working calibre. - Max Forrer's Beta project must not be confused with the later Beta 1, Beta 2 calibers under the direction of Roger Welinger and the later Beta 21 caliber, which were all high frequency quartz wrist watches.

Initiative

On May 7, 1965, it was the last day of our managers three weeks trip to America, I contacted my friend Rolf Lochinger to inform him on the negative results of my research with respect to all combinations of piezoelectric ceramics or crystals with metallic resonators, say for oscillators as well as for vibrating motors. This as a consequence of the very different physical parameters and their mismatch. The only possibility to increase the quality of the oscillator seemed to me a single crystal quartz for the oscillator. At the same time we were reviewing Max Forrer's Beta project and its technical and qualitative limitations and came up with the proposition to investigate into wrist watches which were driven by an increased frequency quartz oscillator, rather then low frequency metallic tuning forks.

Based on previous experience with quartz, my proposal was to use a single crystal quartz oscillator at acoustic frequency, say in the range of 10 kHz, miniaturize it by orders of magnitude down to dimensions required for wrist watches. The reqirement of size and power consumption was here predominant. Lochinger proposed to investigate into integrated electronic circuits suited to master increased divisional ratios. Here the requirements of power consumtion was predominant. This was a true alternative to the existing Beta project, see above. True, the new project was risky and definitely not to the mind of our cautious department head but would certainly have a great impact on the watch industry if successful. Frei and Lochinger started their initiative immediately and agreed mutually to investigate into a new project.

New Strategy

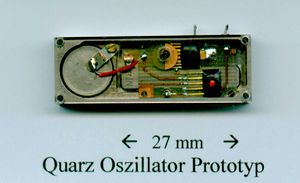

In November, 1965 Roger Wellinger, director CEH and responsible for the yearly strategy and plan, declared the "montre-bracelet à quartz" to become the primary strategic goal for the year 1966.[4] This was a direct consequence of Armin Frei having designed, built and operated successfully a miniaturized quartz oscillator prototype showing feasibility of a quartz wrist watch in the 10 kHz range in 4Q65. In 1Q66 Frei disposed already of a miniaturized quartz oscillator prototype with an 8192 Hz quartz resonator (picture), a novel fully integrated driver circuit running at less than four microamps current consumption (black epoxy covered IC with red dot) and a frequency adjustment set up (upper black epoxy covered IC without a dot), all these components survived till and including the industrial phase with minor improvements only. At that time the term "montre-bracelet à quartz" appeared the first time officially in CEH's documents, and it had to be defended against the many internal and external opponents of this new direction. Never mind the rest of the quartz wrist watch was still not worked out yet or decided upon, Wellinger requested that a general systems invention disclosures on the "Montre-bracelet électronique à quartz" had to be worked out.[5] To be conform with the Swiss watch industry and to warrant his carreer oportunities the head of the circuits department, Max Forrer refused to take on the new quartz wrist watch project. This in turn forced Wellinger to assume full responsibility on Frei's quartz wrist watch project, caused substantial agonies within management and eventually terminated Forrer's low frequencies Beta project with the metallic tuning fork and electromagnetic and piezoelectric actuators. – The situation at Seiko, the Japanese competitor, had been much different. They could rely on the experience with quartz clocks and electronic time keeping which they collected since 1956 (Olympics). They were developing their own quartz technology since 1958 and gradually developed quartz resonators for clocks, pocket watches and then for men's wrist watches successively.

The first Quartz Wrist Watch: Beta 1

World first

The first quartz wrist watch was Beta 1 and it had been built at the Centre Electronique Horloger. The first unit of a series of five was assembled and tested at the CEH in July 1967. Since Seiko does not communicate any details about their first quartz wrist watch, we can firmly conclude that Beta 1 was the world's first quartz wrist watch world wide. The new watch was packed into a standard square case (picture), this was necessary because the quartz case itself was straight with a length of 27 mm. However, the overall dimensions satisfied perfectly the requirements set by the watch industry to qualify for a men's wrist watch. The watch with the identification number CEH-1020 was tested at the Observatory in Neuchâtel as of August 13, 1967,[6] and reached a classification of 0.189, which means an improvement of about one order of magnitude as compared to classical chronometers.[7] The classification was also much better than the one which was reached by tuning fork watches during the same period. Beta 1 was equipped with a stepping motor activating the seconds hand step by step. The alternative and later model Beta 2 was equipped with the same quartz oscillator like Beta 1, but the second hand was actuated by a 56 Hz vibrating motor and a ratchet wheel.

Beta 1 and its Components

Beta 1

Beta 1 became the code name of the first quartz wrist watch. The miniaturized quartz oscillator was developed 1965/66 by Armin Frei. The same setup was used for Beta 2, a current saving alternative quartz wrist watch and later on with minor improvements in the industrial version Beta 21. The first working prototype of Beta 1, CEH 1020 had been assembled by Jean Hermann and François Niklès in July 1967.[8] The main elements of the watch and their primary contributors, including parts and as well as concepts are described below:

Quartz Resonator

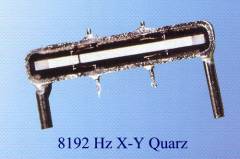

While the size of commercial quartz standards of those days was as big as radio tubes, we had to strive for physical dimensions to be small enough to allow the device to be mounted inside a men's wrist watch case. To keep the electronics simple, the frequency had to be 2 to the power of n (n being an integer) in Hertz in order to produce pulses with a period of one second at the end of the divider chain. Requirements, which are very much contradictory, because if the dimensions are reduced the frequency goes up and vice versa. Further we learned from experiments that quartz resonators with the shape of a tuning fork and fabricated with the technology of those days exhibit a much inferior factor of quality Q as compared to straight quartz bars. The solution to all these requirements was an x-y cut quartz bar with a length of 24 mm and with an eigenfrequency of 213 = 8192 Hz (picture). The small dimensions of the quartz in its metal case as well as the extremely stringent requirements of mechanical precision, stability and life time required special attention with regards to most of the physical parameters: Leakage rates of the case and its feeds through had to be inferior to 5 10-12 Torr ltr/s, organic and anorganic deposition on the surface had to be less than 20 Angstrom thick, metallurgy and soldering of wires onto the quartz surfaces had to be free from any unwanted inclusion, high precision soldering within a fraction of one millimeter was required to reach high quality factors of the resonator and many others. The quartz on the picture was developed and tested by Armin Frei in 1965, Oscilloquartz in Neuchâtel provided for the raw material and Richard Challandes was responsible for the assembly. X-Y cut bar quartz, similar to the one on the picture but with increased frequency, had been produced in Switzerland for watches until 1977. As of 1979 the Swiss watch industry produced their 32 kHz quartz tuning fork resonators in Grenchen, Solothurn licensing Jürgen Staudte's patent on etching quartz tuning forks (USA Patent Jürgen Staudte, 1972).

Driver Circuit

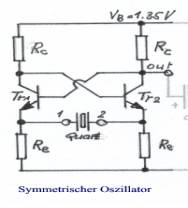

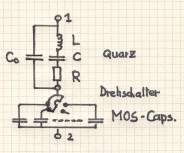

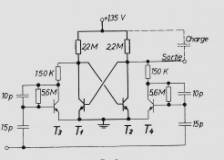

A number a different circuits for driving quartz oscillators were available at the time (Clapp oscillator, etc.), none of them fulfilled the necessary requirements for our quartz wrist watch: Say no coupling capacitances, low total resistors value on the chip, tolerance to the integrated circuits fabrication process and its deviations, rigid operational stability and low power consumption. This for bipolar IC's, as well as for low battery voltages. – The newly developed, symmetric cross coupled driver circuit as shown on the picture incorporates a minimum of four resistors with pair wise equal values Rc and Re as well as two transistors Tr1 and Tr2 and fullfils the above requirements extremely well. The emitter resistors serve as current sources and the collector resistors provide for the negative impedances to drive the quartz. The circuit exhibits a negative impedance of -2Rc approximately measured between the contacts 1 and 2. The circuit was very tolerant to various applications and conditions, and easy to fabricate. It took our specialists of the semiconductor pilot line, Raymond Guye and his colleges, less than two months to ship the first fully integrated properly working chips. The circuit was developed and tested by Armin Frei in 1965 and 1966.

Frequency Adjustment

The first step in the process of adjusting the frequency to the desired value was carefully grinding off surplus material and weight at the ends of the quartz bar until a frequency was reached which, after evacuation of the case, resulted in exactly 213 Hz . A very difficult and tedious job indeed. A fourteen stage divider chain would bring this frequency down to exactly one half of one Hz required to drive the stepping motor. – What about aging and other disturbing effects afterwards and during wear? To take care of this a fine tuning mechanism was needed. A stepwise variable capacitor was hooked up in series with the quartz to change the oscillating frequency of the quartz assembly by 0.2 sec/day upward or downward (picture). At that time Fritz Leuenberger of the semiconductor department started his research on MOS transistors, an excellent chance to integrate on a single chip a series of discrete MOS capacitors, high value and small volume, exactly what we wanted. The design and layout was made in 1966 by Armin Frei, the semiconductor department delivered the MOS capacitor chip and the watch maker technician Claude Challandes designed the miniature switch.

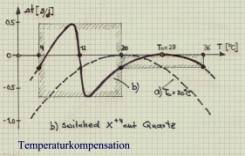

Temperature Compensation

The irregularities in time keeping of quartz wrist watches are due to the temperature sensitivity of the various physical parameters of the quartz crystal itself and are not due to the electronics attached to it. The deviation in time is measured in seconds per day as a function of temperature. The resulting plot, usually displayed between 4° C and 36° C is a complicated function of the cutting angles relative to the axes of the quartz crystal itself. At the time it was well known, that the x-y cut quartz crystals exhibit parabolic curvees according to the curve a) in the picture. We were very much aware that the manufacturers of the current mechanical watches were keen to keep the temperature deviation as small as possible, so we engaged strongly in the disciplines of temperature compensation. First investigations using temperature sensitive resistors and capacitors were not very successful. Jean Hermann proposed in 1967, shortly before the very first quartz wrist watch was operating, a scheme using the parabolic behavior twice and a switch to connect a compensating capacitor at 12°C according to curve b). This scheme was easy to implement, produced favorable results with the observatory tests and was effective during daily usage. Yet it required extensive interventions by the laboratory director on behalf of the department head in order not to drop the brilliant idea. The resulting Thermo Compensation Module (TCM) was developed by Jean Hermann and was implemented using MOS technology by Fritz Leuenberger and his group in 1967.

Frequency Dvider

Since the very beginning of the quartz wrist watch project Armin Frei decided that the oscillating frequency of the quartz had to be to 213 = 8192 Hz. Consequently for Beta 1 using a stepping motor to drive the second hand, see below, a total of 14 binary flip-flop stages were required to drive the motor of the watch with pulses of half a Hertz repetition frequency. The flip-flops which were finally incorporated in the Beta 1 prototypes (picture), were designed by Jean Fellrath and implemented in integrated form by Raymond Guye and his group in bipolar technology. The circuits were optimized for low power consumption of approximately one microamp per stage and for high operational stability. While integrated counter stages at microwatt level existed since before, the flip-flop shown exhibits a new type of triggering circuits, one of them on each side, and it also uses direct coupling between collectors and opposite base similar to the oscillator circuits, see above. - In bipolar technology the divider chain with 14 stages represented a big load for the battery, limiting its lifetime to less than one year, much to the concern of certain members of the governing board. The immediate solution to that would have been a reduction of the number of divider stages, say 5, reduce the frequency to 256 Hz rather than half a Hz and use a vibrating motor rather then a stepping motor. This was alternatively proposed with the Beta 2 and the Beta 21 projects 1967 and 1968 respectively. - However the real solution to the power consumption problem were ultimately the Complementary Metal Oxide Silicon circuits (CMOS), which had been invented in USA (Frank Wanlass, 1963) a couple of years before.

Stepping Motor

All that was left was to convert the pulses appearing at the end of the divider chain into step by step advancements of the second hand. Jean Hermann and François Niklès proposed in 1967 a simple solution of such a stepping motor for Beta 1 as seen in the picture. The setup incorporated an anchor wheel and an anchor which were responsible for the go and stop of the second hand. Much different as in mechanical watches, where the anchor and the anchor wheel act as escapement, here the anchor drives the anchor wheel by wiggling forth and back. The anchor was activated by means of a bobbin coil, which was attached to the anchor and which was magnetized by bipolar electric pulses. The duration and the amplitude of the pulses had to be well controlled to warrant proper operation and to save battery power. The duration of the pulses were derived from the pulse pattern appearing along the divider chain using boolean logic. The concept and the basics had been worked out as early as 1966.

Beta 2

Autonomy

The office of the governing assembly had little sympathy for the new direction with the quartz wrist watch. They were hoping for an electronic watch, exhibiting at least one advantage compared with existing electronic watches, remember the strategy and here was a watch with a battery life time of less than one year! One representative of the office, not very familiar with electronics and its progress made it a must: Life time had to be equal or longer than one year.

Current Saving Version

This in turn was the starting point of a fatal new strategic direction: A current saving alternative project, called Beta 2, was proposed and initiated in November 1966 by Max Forrer. Beta 2 was using the same oscillator like Beta 1, but had only five flip-flops instead of fourteen as Beta 1. With five stages, a frequency of 256 Hz was reached, just right to drive one of Henri Oguey's vibrating motors. Battery life time was above one year. The first Beta 2 calibre was assembled in August 1967, one month later than Beta 1.

Beta 21

Industrial Version

After the splendid celebration of the outstanding results reached with Beta 1 and Beta 2 following the observatory tests, on February 15, 1968 investigations on how to establish a technology transfer from the prototypes towards a product started immediately. First it was decided to favor Beta 2, not Beta 1. This decision was commented by Henri Oguey and Henri Schneider simply by: "Au vu de l'expérience aquise sur les prototypes, seul le système Bêta 2 entre en ligne de compter pour assurer une durée de vie de la pile supérieure à un an." The industrial calibre was named Beta 21, consisted of the 8192 Hz oscillator, a five stage binary divider chain and the vibrating motor at 256 Hz. On April 10, 1970, during the "Foire Suisse de Bâle", four months after Seiko's Astron SQ35, some 20 Swiss firms launched their products all incorporating the Beta 21 movement.

Industrial Flop

Beta 21 turned out to be a flop. Some 6000 units were sold, then the line with the vibrating motor was discontinued. To solve an intermediate power problem (autonomy) by pushing the vibrating motor version turned out to be a severe strategic error with a number of consequences. Indeed, the power problem was not a systems problem but a semiconductor problem. Using Complementary Metal Oxide Semiconductors (CMOS) circuit technology instead of Bipolars (BIP) would have saved exceeding amounts of energy by orders of magnitude. CMOS was invented in 1963 and was applied later on throughout the watch industry. The CEH started early on MOS, however produced stable CMOS with silicon gate technology at a voltage level of 1.35 V only after 1972. Instead of pushing research after the splendid success at the observatory CEH engaged excessively in technology transfer and manufacturing, losing lead time and research competence. – Not enough of all that, with their Astron 35SC the Japanese proved feasibility of an industrial watch with a stepping motor and battery lifetime of over one year.

Chronology of the First Quartz Wrist Watch

May 7, 1965: Armin Frei and Rolf Lochinger started the quartz wrist watch project. Frei proposed to concentrate on quartz oscillators suitable for wrist watches and Lochinger proposed to investigate into divider circuits and drivers. Although the strategy did not plan for any such high frequency project Frei and Lochinger started their investigations immediately. November 26, 1965: Roger Wellinger, director CEH declared the "montre-bracelet à quartz" to be a strategic goal. This was a consequence of the availability of a miniaturized quartz oscillator with low energy consumption and with a size smaller than 27 mm by Frei. This is the first time that the "montre bracelet à quartz" was mentioned in a strategic document at the CEH. The task was formulated as: "Construction, mise au point et évaluation du prototype du calibre".[4] Max Forrer rejected to install the new quartz project in his department, which forced Roger Wellinger to assume project responsibility of the quartz works. July, 1967: The first fully operational and complete quartz wrist watch, probably worldwide, had been assembled by Jean Hermann, François Niklès et al. The watch Beta 1 consisted of a 8192 Hz quartz oscillator, a fourteen stage divider stage and an electro dynamic stepping motor. Testing of the temperature compensation module during five days demonstrated proper operation. With this the CEH disposes of a reliable documentation of the priority of the first quartz wrist watch worldwide.[8] August 13, 1967: About one month later, the first quartz wrist watch Beta 1 with connotation CEH-1020 was delivered to the Observatory of Neuchâtel and was immediately submitted for tests in the category of "Chronomètres-bracelet". The resulting number of classification was 0.189, a value at least one order of magnitude better than the other mechanical competitors in the same category. Later on, a total of ten other quartz wrist watches from CEH (Beta 1 and Beta 2) were delivered for tests. On November 11, 1967 a total of four quartz wrist watches from Seiko, Japan were submitted. The average number of classification of the four best watches of either CEH or Seiko were 0.166 and 0.873 respectively.[7] With this the CEH watches were winners in time and quality - at least in 1967. The differences in the number of classification within the group of the CEH watches result from the thermo compensation and its adjustments and not from the difference of systems.August 1967: The first calibers Beta 2 were completed. They were submitted for tests at the observatory on September 17, 1967. Beta 2 consists of the 8192 Hz oscillator, a five stage divider and a vibrating motor. In 1968 it had been decided to start an industrial version based on the Beta 2 principle for reasons of battery lifetime. December 26, 1969: Introduction of Seiko's Astron SQ35 on the market, the worldwide first commercial quartz wrist watch. Seiko's watch was nice, had a battery lifetime of more than a year, even though it had a stepping motor, and its electronics were based on a new hybrid technology incorporating some 200 parts. April 10, 1970: Introduction of the Beta 21 caliber, the industrial version of Beta 2, marketed by some 20 Swiss watch manufacturers during the "Foire Suisse de Bâle".

Rectification

The world first quartz wrist watch was Beta 1 and not Beta 21, as postulated incorrectly by the Swiss watch industry. Further, the first industrial quartz wrist watch was not Beta 21 either, but Seiko's Astron 35SC. - Beta 1 was assembled in July 1967 at the CEH. In the sequel the watch had been tested successfully by the Observatory in Neuchâtel, Switzerland. It had an 8192 Hz quartz, a long fourteen stages frequency divider chain and a stepping motor. Beta 1 followed a concept which later on proved successful by non Swiss manufacturers. - Unfortunately since 1968 the concept of Beta 1 had not been pursued any further by CEH management, which in turn favored Beta 2, an alternative version introduced later by Max Forrer and Henri Oguey in order to save power. However Beta 2 used the same 8192 Hz quartz as Beta 1 but it had a frequency divider chain with five stages only and a vibrating motor rather then a stepping motor. Beta 21 was based on Beta 2 and unfortunately became the industrial version. Some 20 Swiss watch manufacturer simultaneously launched Beta 21 on the market in 1970, some 4 months after Seiko had announced their famous Astron 35SC. Beta 21 with its vibrating motor turned out to be a misconception and was abandoned after a short period of time.

The previous Beta project by Max Forrer, manager of the circuits section consisted of a metallic tuning fork, not a quartz, a small frequency divider and a vibrating motor, not a stepping motor, and lasted from 1963 till YE65. - The new and aggressive quartz wrist watch project initiated by Armin Frei and Rolf Lochinger in May, 1965 changed the previous Beta strategy completely.

Before 1966 there was no quartz wrist watch strategy or project in the CEH plan. The majority of the recognized Swiss experts denied the feasibility of a quartz wrist watch and most of the industrial officials rejected the idea of a new market with quartz wrist watches explicitly. – All other claims are incorrect.

This investigations had been necessary in order to give proper recognition to the contributors of the first quartz wrist watch and identify their contributions, some of them were key. The policy of Max Forrer et al. through out the years to ignore key contributors and play down important contributions is unfair and had to be corrected. E.g. the text of the Smithonian Institution, NMAH, on "Inventors of the First Quartz Wrist Watch" had to be corrected in 2003.[9] Further, an open door case had to be conducted by the former laboratory director against Forrer in order to correct the authorship of his IEEE conference paper "A Flexure Mode Quartz for an Electronic Wrist-Watch" [10] and to denounce plagiarism. Other similar cases (Paris 1969) are pending.

Bibliography

- ↑ M. Forrer: Mémo Technique 101, CEH, February 25, 1965

- ↑ M. Hetzel: The Application of Electricity and Electronics to Wrist Watches, Horological Journal, 1963, p 233

- ↑ R. Wellinger: Orientations calibres, Protocole séance du bureau d'administration, April 13, 1965

- ↑ Jump up to: 4.0 4.1 R. Wellinger: CEH Programme de travail 1966, Protocole séance du bureau d'administration, November 26, 1965

- ↑ M. Forrer, A. Frei, R. Lochinger, H. Oguey: Montre-bracelet électronique à quartz, Rapport d'invention, CEH 66/73, February 4, 1966

- ↑ L. F. Trueb: Die weltweit erste Quarz-Armbanduhr, gold'or 2/07

- ↑ Jump up to: 7.0 7.1 République et Canton de Neuchâtel: Concours chronométrique 1967, February 15, 1968

- ↑ Jump up to: 8.0 8.1 J. Hermann: Rapport d'activité du mois de Juillet 1967, CEH, July 31, 1967

- ↑ Mrs. C. Stephens: "Swiss Inventors", http://invention.smithsonian.org/centerpieces/quartz/inventors/researchers.html Smithonian Institute, NMAH Washington, corrected 2003

- ↑ R. Wellinger: "Rectification concerning a 1969 publication on Quartz Wrist Watches", March 23, 2005 refering to an impertinent plagiarism by: M. Forrer: "A Flexure Mode Quartz for an Electronic Wrist-Watch" Proceedings 33. Annual Frequency Control Symposium, Atlantic City, May 1969, pp.157-162.

Copyright 2009 by Armin H. Frei, Zurich Switzerland

Photos Courtesy CEH/CSEM, Neuchatel Switzerland

Further Reading

Engineering time: inventing the quartz wristwatch, C. E. Stephens, Frequency Control Symposium and PDA Exhibition, 2001. Proceedings of the 2001 IEEE International, 2001, Pages: 2 - 3, DOI: 10.1109/FREQ.2001.956151

On Time: How America Has Learned to Live Life by the Clock, Carlene E. Stephens, Bulfinch, August 2002; ISBN-10: 0821227793, ISBN-13: 978-0821227794

Pioneering Work on the Quartz Electronic Wristwatch, 1962-1967 IEEE Milestone

Electronic Quartz Wristwatch, 1969 IEEE Milestone

The First Quartz Wrist Watch Assembling Crew, A First Hand History by Armin H. Frei

http://quartzwristwatch.org New website of the Dr. Armin H. Frei heritage estate