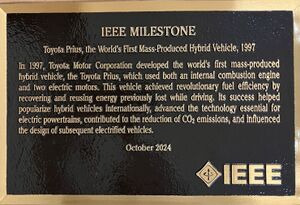

Milestones:Toyota Prius, the World's First Mass-Produced Hybrid Vehicle, 1997

Title

Toyota Prius, the World's First Mass-Produced Hybrid Vehicle, 1997

Citation

In 1997, Toyota Motor Corporation developed the world's first mass-produced hybrid vehicle, the Toyota Prius, which used both an internal combustion engine and two electric motors. This vehicle achieved revolutionary fuel efficiency by recovering and reusing energy previously lost while driving. Its success helped popularize hybrid vehicles internationally, advanced the technology essential for electric powertrains, contributed to the reduction of CO2 emissions, and influenced the design of subsequent electrified vehicles.

Street address(es) and GPS coordinates of the Milestone Plaque Sites

1, Toyota-cho, Toyota, Aichi, 471-8572, Japan (35.055465, 137.160114)

Details of the physical location of the plaque

Affixed to a stand in the entrance lobby on the ground floor of the Toyota Technical Center Headquarters, the building where the Prius was developed.

How the plaque site is protected/secured

Accessible 8am-5pm on corporate business days, except during holiday periods; building security.

Historical significance of the work

(1) Birth of the world's first mass-produced hybrid system

- In the 1990s, when cars powered by internal combustion engines burning fossil fuels were mainstream, there was a need to develop significantly more energy-efficient driving systems, such as systems with double the fuel efficiency, to address energy depletion.

- While continuous efforts were made to improve the performance of internal combustion engines, it was believed that conventional approaches would not achieve double the fuel efficiency. On the other hand, the development of electric vehicles had also been underway at the time. Motors could provide high torque at low speeds, but to achieve high-speed performance, large motors and batteries were required, making them impractical with the technology available at the time.

- To achieve performance that could not be attained through conventional approaches, a mass-produced hybrid vehicle was developed that utilized both an internal combustion engine and an electric motor, combining their respective advantages. In 1997, it was released as the Prius [1].

(2) Types of hybrid systems by structure and series-parallel hybrid system

- At the time, three main types of hybrid vehicles were considered:

- i) Series hybrid system, which generates electricity with the internal combustion engine and runs solely on the motor;

- ii) Parallel hybrid system, which has both an internal combustion engine and a transmission like conventional vehicles, with the motor used as an assist;

- iii) Series-parallel hybrid system, which connects the internal combustion engine and two motor-generators with a planetary gear, combining the advantages of both i) and ii) and offering the greatest improvement in fuel efficiency.

- the Prius adopted iii), the series-parallel hybrid system [2].

(3) Types of hybrid systems by function and EV driving

- In addition to the three classifications based on the series, parallel, and series-parallel structures mentioned earlier, hybrid systems are also classified based on their functionalities:

- a) Mild hybrid system, where the motor assists the internal combustion engine

- b) Full hybrid system, where the vehicle can run on the motor alone by stopping the internal combustion engine.

- Toyota's series-parallel hybrid system belongs to the full hybrid system. This system has the capability to stop the engine while stationary or during EV driving, run solely on the electric motor at low speeds, efficiently use the internal combustion engine at an optimal rotational speed, recover energy during deceleration and unused energy from the internal combustion engine, store it in the battery, and reuse it for driving.

- It achieved twice the fuel efficiency of conventional vehicles powered by internal combustion engines [3]. Additionally, immediately after the engine starts, the system allows for 100% motor-driven propulsion, which optimally warms up the exhaust gas purification catalyst, dramatically reducing exhaust emissions [4].

(4) Subsequent developments of the hybrid system

- The series-parallel hybrid system has continued to improve its performance while maintaining its basic structure and has been adopted in various vehicles. In 1998, approximately 20,000 units were produced in Japan [5], but as of 2022, Toyota hybrid vehicles are sold in over 2.7 million units annually worldwide [6], being well-received by customers as fuel-efficient eco-cars.

- Furthermore, the technologies developed during this period, such as batteries, motors, and power control units, have also been applied to current electrified vehicles, including PHEVs, BEVs, and FCEVs.

Obstacles (technical, political, geographic) that needed to be overcome

(1) Challenges of the Pre-Prius Eco-Cars

- i) History and Challenges of Hybrid Cars

- The history of hybrid cars dates back to the early1900s when the world's first hybrid car was introduced in Europe. Since then, attempts to develop hybrid cars have been made intermittently, with various types of hybrid cars being developed worldwide. However, challenges such as the immaturity of component technologies like batteries and motors, high prices, advancements in internal combustion engines and transmissions, and the mitigation of oil crises have slowed down the development. Until the 1990s, only prototypes and limited production models were available from a few manufacturers.

- ii) Environmental Issues and Challenges of Electrified Vehicles

- In the 1990s alongside environmental concerns, preparing for future energy issues such as the depletion and scarcity of petroleum resources became a critical challenge for the automotive industry. Toyota began serious development of battery electric vehicles(BEV) and fuel cell vehicles(FCEV). Research rapidly transitioned to practical development, and in 1996, Toyota launched BEV. It adopted newly developed nickel-metal hydride batteries and was first released in Japan, followed by the United States in 1997 {7}. However, due to high prices, limited driving range, and long charging times, it did not achieve mass production.

- iii) Car of the 21st Century

- In 1993, Toyota initiated a project to create a leading car for the 21st century. The development of a car with "overwhelming fuel efficiency while maintaining or improving the convenience and comfort of current cars" began.

- The key features of this car, which aimed to overcome the challenges faced by environmentally conscious cars, are as follows:

- Twice the fuel efficiency of conventional cars with sufficient driving range,

- without the need for special infrastructure,

- smooth and responsive acceleration,

- an affordable price accessible to customers.

- To achieve these goals, the series-parallel hybrid system was selected as the potential solution among various hybrid systems.

(2) New Technologies Required to make Hybrid-systems usable in products

- Toyota's series-parallel hybrid system relies on complex control of multiple components, including two motor generators, a battery, and an engine, to adapt to the vehicle's driving conditions. To incorporate electrical components into the vehicle, it was necessary to reduce size and weight, increase output and efficiency, and extend dulability of each component. Furthermore, to make it a mass-produced product that customers can use without inconvenience compared to conventional vehicles, many new technologies and approaches were required. Some of these are listed below.

- i) Reduction of vibration caused by frequent engine stop-start during driving

- During vehicle stops and while driving, there are frequent occurrences of engine start-stop. It is important to reduce the vibration during these times to avoid discomfort for customers. Therefore, new ideas were incorporated to significantly reduce the vibration during engine start-stop, such as using a high-output motor generator to instantaneously increase the engine's rotation speed at startup and significantly delaying the intake timing using the engine's variable valve timing (VVT) mechanism to reduce compression reaction force. These new ideas greatly reduced the vibration during engine start-stop [3].

- ii) Energy regeneration during deceleration and hydraulic braking

- During deceleration, the driving motor generator among the two motor generators is used as a generator for energy regeneration. To ensure strong braking or reliable braking at extremely low speeds, it is necessary to smoothly switch from regenerative braking to hydraulic braking without discomfort. This contributes to customer safety and peace of mind. Therefore, a new coordination system between hydraulic braking and regenerative braking was developed [8]. Since hydraulic braking has lower responsiveness compared to motor generators, it was necessary to enhance this. In the hybrid system, the idea of putting the minimum necessary brake pressure in standby mode was successful in improving responsiveness.

- iii) Cooling of electrical components

- Battery :

- The battery undergoes repeated charging and discharging during driving. Air cooling using outside air is common, but cooling performance is insufficient at temperatures above 40°C. Therefore, stable cabin air temperature is used for cooling, allowing for reduced battery temperature and ensuring the same convenience as conventional vehicles even at high outside temperatures. This battery air cooling system has become the mainstream cooling method for hybrid vehicle batteries.

- Battery :

- Motor generators, inverters:

- In hybrid vehicles, motor generators and inverters need to be cooled not only to dissipate heat generated during operation but also to prevent the influence of heat from the engine as they are installed near the engine. Therefore, the MG adopts an oil cooling method using transmission fluid, and the inverter adopts a dedicated cooling water method.

- Motor generators, inverters:

- iv) Emission reduction technology

- Frequent engine start-stop deteriorates exhaust gas emissions. To solve this, the engine rotation speed is rapidly started and stopped using a high-output motor generator, and the fuel injection amount during engine start-stop is optimized. This emission reduction technology is widely applied to current HEVs and PHEVs [3].

(3) Shortening development time through the use of model-based development

- The hybrid system has many components, and following the traditional development process, which focuses on confirmation through prototyping, would result in a very long development time, which was not practical.

- However, the development team aimed to present the concept of the next-generation car by the 21st century and pushed for an ultra-short development period of 4 and a half years, from planning and system determination to element technology development, product development, and production preparation.

- Therefore, the concept of model-based development (MBD) was introduced to optimize the design and control of these components. Although it is common now, there were few examples of using MBD in automotive development at that time.

- The selection of the series-parallel hybrid from numerous hybrid systems, determination of specifications for each component of the series-parallel hybrid, and determination of hybrid system control specifications were repeatedly simulated to derive optimal solutions before prototyping each component. This significantly shortened the development time and allowed for rapid development.

Features that set this work apart from similar achievements

(1) Other companies' hybrid vehicles of the same generation

- After the release of the Toyota Prius in 1997, the Honda Insight, a mild hybrid using a parallel system, was released in 1999. In 2000, the Nissan Tino, a full hybrid, was released in limited quantities. The release of the Prius further heightened awareness of environmental issues, leading to increased development and market entry of hybrid cars by many automakers. Toyota's hybrid system has maintained the same basic structure from the early days of mass production hybrid cars to the present, while continuously evolving its performance.

(2) Other types of hybrid systems by Toyota

- Toyota has also conducted research and development on various hybrid systems, including series hybrid, mild hybrid, and diesel hybrid. Some of these systems have been released in the Japanese market. However, in 1997, it was confirmed that the 2-motor + planetary gear series-parallel hybrid system installed in the Prius had superior fuel efficiency, performance, and cost balance compared to other systems. As a result, it expanded to many other models besides the Prius.

(3) For further advancement of fuel-efficient and environmentally friendly cars

- The proliferation of the hybrid system laid the foundation that enabled Toyota to establish the vehicle drive battery, motor, and power control unit technologies shared by various electrified vehicles in the present day. Of those technologies, 23,740 patents related to motors, power control units, system control, among others, have been made available under a royalty-free license from April 2019 to the end of 2030. This action is unique to Toyota Motor Corporation and will contribute to making electric vehicles more widespread and reducing CO2 emissions [9].

Significant references

References:

[1] Motor Fan Special Edition - All about PRIUS: published by SAN-EI CORPORATION on March 29,1998.

- A review magazine published after the release of PRIUS. It features the concept, technology, and impressions of journalists about PRIUS, spanning 70 pages.

[2] PRIUS PRESS INFORMATION '97 by Toyota Motor Corporation.

- For Representative hybrid system, refer to figures on page 11-12.

[3] T. Takaoka, "Super High Efficient Gasoline Engine for the Toyota Hybrid System", 1998 FISITA F98T/P097.

- For vibration reduction, refer to section 5.5 "Vibration countermeasures when starting and stopping" on page 13.

- For Fuel Economy of Japanese 10-15 mode, refer to Figure 25 on page 15.

- For Emission reduction technology, refer to section 5.4 "Reduction of exhaust emissions" on page 11.

[4] M. Okamura, "The Evolution of Electric Components in Prius", IEEJ Journal of Industry Applications - Volume 11 Issue1 2022, pages1-6.

- https://www.jstage.jst.go.jp/article/ieejjia/11/1/11_21007126/_pdf/-char/en

- For types of hybrid systems by function and EV driving, please refer to Figure 4 on page 2.

[5] Key Automotive Statistics by Major Countries (2000) Volume 29.

- Company-specific and Model-specific Production Volume in Japan in 1998, page 17.

[6] Sustainability Data Book by Toyota Motor Corporation.

- https://global.toyota/pages/global_toyota/sustainability/report/sdb/sdb23_en.pdf

- Global Electrified Vehicles Sales on page 48, Third-party Verification on page 55

[7] News Release by Toyota Motor Corporation, "Toyota Starts Monitoring Its New RAV4L Electric Vehicle", 1995.

[8] T. Yaegashi, "Toyota Hybrid System: Its Concept and Technologies", FISITA Congress-Vol.1998, F98TP095, 1998, Pages 4241-4251.

- For the new coordination system between hydraulic braking and regenerative braking, refer to section 2. 3. (6) on page 7 and 2. 4. (1) on page 7

[9] News Release by Toyota Motor Corpration, "Providing Licenses Royalty-Free", 2019.

[10] A. Nagasaka,"Development of the Hybrid/Battery ECU for the Toyota Hybrid System", SAE Technical Paper Series, Society of Automotive Engineers, 1998, pages 1721-1730.

[11] A. Kimura, "Drive force control of a parallel-series hybrid system", JSAE Review, Society of Automotive Engineers of Japan-Vol.20 No.3, 1999, pages 337-341.

[12] S. Sasaki,"Toyota's Newly Developed Electric-Gasoline Engine Hybrid Powertrain System' EVS14, 1997.

Supporting materials

- Toyota Prius Milestone Report

- IEEE Spectrum story: The Toyota Prius Transformed the Auto Industry: The first mass-produced hybrid EV is an IEEE milestone