First-Hand:My Life in Power Electronics

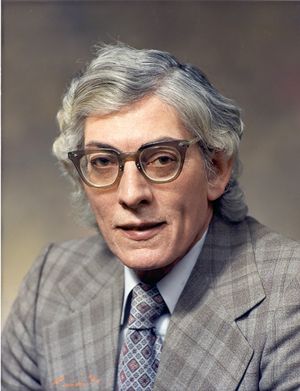

Contributed by Bimal K. Bose, IEEE Life Fellow

Undergraduate Engineering in India during the 1950s

I was an undergraduate student in Bengal Engineering College (BEC, now Indian Institute of Engineering Science and Technology or IIEST Shibpur), India, from 1952 to 1956. The BEC was an old institution, established in 1856, and renowned for undergraduate education. The only other comparable institution in India at that time was Thomason College of Civil Engineering (now Indian Institute of Technology Roorkee, or IITR), established in 1853. There were, of course, many regional degree- and diploma-granting engineering colleges. Engineering education was not very developed after India established its independence in 1947. Students seeking higher engineering degrees normally studied in the universities of the United Kingdom. Gradually, after independence, the government of India established a number of Indian Institutes of Technologies (IITs) that grew to be world-class in educational quality and standard of research.

The BEC had a large electrical machines laboratory where, in our senior year, we were assigned machine experiments on Ward-Leonard speed control, Hopkinson’s test (dc motor-regeneration with a coupled dc machine), synchronization of an alternator on a three-phase bus with the three-lamp method, and Schrage motor speed control. Professor Ralph Benedict from the University of Wisconsin, Madison, visited us for one year and taught a course on mercury-arc rectifiers. We had two lab experiments on glass-bulb mercury-arc rectifiers. One was a single-phase, full-wave, diode rectifier with center-tapped transformer, where we started the arc through an auxiliary anode by tilting the bulb. The other was a six-phase, half-wave, grid-controlled rectifier, where the arc was initiated by a current pulse through an auxiliary anode.

Power Engineering in India in the 1950s

After graduation, I started my career as a power engineer in India in the mid-1950s. I was an engineer in a hydroelectric power company in the early days, and then I started teaching power engineering courses (generation, transmission, distribution, and electric machines) at BEC. The so-called power electronics field was unknown in those days. Power electronics was termed “industrial electronics,” because gas tubes were used mainly in industrial applications, whereas vacuum tubes were used in signal processing and communication. Gas-tube electronics, based on thyratrons and ignitrons, and glass-bulb and steel-tank mercury arc and ignitron rectifiers were widely used in industry. In India, most of the power conversions and control were based on traditional rotating machines, but gradually mercury-arc converters were introduced. The term “power electronics” gained wide acceptance in the early 1970s.

M.S. degree at University of Wisconsin

In those days, a spectacular revolution was going on in the field of electronics. In 1948, Bardeen, Brattain, and Shockley of Bell Laboratories invented the transistor that started the solid-state electronics revolution. In 1958, General Electric (GE) commercially introduced the silicon-controlled rectifier (SCR) or thyristor (solid-state thyratron) based on the PNPN triggering transistor invented by Bell Labs in 1956. This was the beginning of the second electronics revolution or age of solid-state power electronics. Silicon power diodes started appearing in 1950s, replacing the old selenium, copper oxide, and gas-tube diodes, and they created a lot of excitement.

I pursued my master’s degree at the University of Wisconsin, Madison, from 1958 to 1960. I was selected as a scholar for the USA-India Technical Cooperation Mission (TCM, which later became United States Agency for International Development [USAID]), and my expenses for the Wisconsin study were covered by TCM. Besides education, the TCM organized an excellent program for my all-round experience with the American educational system. Under the terms of this program, I was required to teach in an Indian university for a minimum period of three years.

The University of Wisconsin was famous for its power engineering program. Prof. Benedict was my thesis adviser, and he also taught me in an industrial electronics course. There was an industrial electronics laboratory, where we conducted experiments on a thyratron dc motor drive and ignitron welding control, etc. I conducted my M.S. research on the study of three-phase, diode-bridge rectifier harmonics and their effects on general utility systems using a distributed-parameter, LC-model transmission line. With the help of a harmonic wave analyzer, I could demonstrate the distribution of harmonics along the line and the resonance voltage boosting effect with a particular harmonic.

Coming from India to the USA, and Wisconsin in particular, was an exciting experience for me. It was a different world, where people looked so lively and prosperous. With an Indian friend, I rented an apartment where I used to cook Indian food, but during the day, I ate American food in the university cafeteria. Winter weather in Wisconsin was extreme, and sometimes temperature used to fall to -16°F. The streets and the two lakes, Mandota and Manona, in Madison were completely frozen. I found it difficult to walk on the sidewalks and roads with a heavy coat and my briefcase in hand. I could hardly believe that men were ice-fishing on the lakes.

Research on Magnetic Amplifiers (MAs) in India, 1960s

After completing my studies at the University of Wisconsin, I returned to India and joined the faculty at BEC, where I introduced a new course in industrial electronics.

I did my doctoral research at Calcutta University on Ramey magnetic amplifiers from 1960 to 1965. Calcutta University was very famous for research activities in those days and produced a large number of brilliant scientists. Although thyristors were available at that time, Dr. Herbert Storm, a renowned authority in MAs at GE Corporate Research and Development (GE-CRD), Schenectady, NY advised me to work in this area and agreed to be my project adviser remotely. I grew close with Dr. Storm through professional correspondence. There was an era of magnetic amplifiers with saturable core reactors before the modern thyristor era, which were functionally similar to gas-tube or solid-state power electronics. Magnetic amplifiers were bulky but more rugged and reliable than gas-tube electronics, and they were promoted very heavily during World War II and postwar periods, particularly in Germany.

The analytical study of MAs was much more complex than that of thyristor converters. My research was somewhat hybridized with MAs (with silicon diodes), power transistors, and thyristors. My research projects included a magnetic servo amplifier for position control with a two-phase induction servomotor, and multi-channel telemetry encoding systems using MAs with transistors and thyristors. The NASA Langley Research Center in Hampton, Virginia, seriously considered them for satellite-to-earth data transmission. From 1966 to 1971, before immigrating to the United States, I supervised many MA-based research projects at BEC, including a four-quadrant analog multiplier, a dc-to-dc converter, a magnetic servo-amplifier, and a digital voltmeter.

RPI and Research in Modern Power Electronics, 1970s

The year 1971 was momentous for me, as I emigrated from India to the USA and started my academic career at Rensselaer Polytechnic Institute (RPI) as a visiting professor in modern power electronics. The ambitious career opportunities in USA always fascinated me, and unfortunately the political conditions in India were fast deteriorating at that time. Prof. Benedict inspired my emigration to USA. I applied for a faculty position at RPI, but getting an offer while I was in India was not easy. To test my knowledge, the department chairman asked me to submit four doctoral research topics and formulate a full senior/graduate course in power electronics. This was quite a challenge for me as an Indian whose strength was mainly in magnetic amplifiers. However, GE-CRD, which worked closely with RPI’s EE Department, examined my submission and approved it. The official appointment letter from RPI helped me to get my emigration visa or “green card” easily from the American consulate.

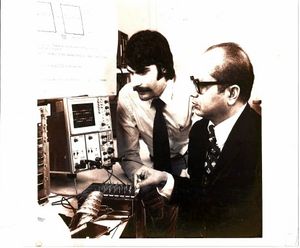

RPI is a private university with a great reputation; the students were brilliant and constantly tested my knowledge in power electronics. To my knowledge, the only other university in the United States that had a power electronics program then was the University of Missouri, Columbia. RPI benefited from its proximity to GE’s research labs in nearby Schenectady, which helped promote my power electronics program. I completed a number of projects such as the development of a transistor ac switch and its application in matrix converter; triac speed control of induction motors; three-phase ac power control with transistors; and a thyristor-saturable core self-oscillating inverter. GE-CRD offered me a part-time (one day per week) consultancy on a GE-CRD engineer’s M.S. project: a thyristor high-frequency resonant-link cycloconverter for power conversion. This again was a challenge, but the project turned out very well. I showed for the first time that a cycloconverter could be used at programmable leading or lagging line displacement power factor (DPF), and as a static VAR compensator (SVC) in extreme cases. As a reward, GE-CRD offered me a full-time job in 1976.

Changing Career Paths from RPI to GE-CRD

I could not refuse GE-CRD’s attractive offer. Having spent sixteen years in university career, I always felt that I had a large gap in my education and expertise. As a graduate student, I did not have much experience getting my hands dirty in fabricating large power converters with complex electronic circuits, or solving the real world EMI (electromagnetic interference) problems of large converters. My doctoral studies were rich with analytical work using complex waveforms, equations, etc., but not with real world applications.

Naturally, I promoted similar analytical studies among my graduate students. As a professor, I had few opportunities to come across practical projects. I advised my students in lab experiments on what oscilloscope waveforms should look like, with lots of sketches on black boards, but I was hesitant to put my hands on breadboards on complex projects. Obviously, I was somewhat nervous with large projects that involved higher levels of power. Power electronics is such an application-oriented practical subject, however, and it was time for me to fill these gaps if I wanted to have real impact as a university professor in the future.

GE-CRD was then considered the ivory tower of power electronics worldwide, and power electronics specialists from all over the world used to visit its labs in Schenectady. All the conferences were then filled with the company’s papers, and there were hardly any papers from universities. I thought it would be very unwise not to accept the GE offer.

Working with Bill McMurray at GE-CRD

The transition to GE-CRD after a 16-year university career was another challenge to meet. My office was in the historic Building 37 in Schenectady, where Ernst Alexanderson, Gabriel Kron, Philip Alger, and other famous scientists had offices. It was a thrilling experience to see so many world-renowned scientists in the hallways and offices. All researchers regardless of background had the title of Electrical Engineer.

I was given a desk and chair in the same room with William “Bill” McMurray (1926 – 2006). Bill is the founding father of power electronics, and the world bows to his memory with deep respect. Bill had honorary doctor of law degree from Concordia University, Canada in 1986. He became an IEEE Fellow in 1980 and a Life Fellow in 1994. He received the Newell Award (1978), the IEEE Lamme Medal (1984), and the IEEE Millennium Medal (2000) for his research contributions. He authored the book The Theory and Design of Cycloconverters (MIT Press, 1972) and was a contributing author in the historic book Principles of Inverter Circuits by Bedford and Hoft (New York; Wiley 1964). The IEEE Power Electronics Society introduced the McMurray Award for Industry Achievements in Power Electronics in 2019 in his honor. All of his papers, particularly those on thyristor-forced commutation techniques, are considered classic contributions in power electronics. His research set the stage for the modern power electronics evolution. He worked at GE-CRD for 35 years with an M.S. degree, but his brain was extremely sharp. He deeply loved mathematics and filled pages after pages with complex equations, which were strewn all over his table and the floor. After a generalized analysis, he loved to draw normalized graphical plots.

I was surprised to see that such a world-famous scientist had barely a chair and desk with a telephone in his office. Bill was a chain smoker, and the room was always filled with smoke. In the later part of his life, he suffered from emphysema, which was the cause of his death. He rarely spoke with others. A young lady secretary with a noisy typewriter sat in the same room. She used to call him an “awful person” because of the heavy smoke in the room and his silence. Although I sat next to Bill, I could rarely speak with him informally. He insisted that I make an appointment for any talk. Once we rode together to Auburn, New York, where GE manufactured thyristors, and he did not talk to me during the entire six-hour journey. He seemed to be thinking the whole time.

Nonetheless, we had an excellent working relationship, and Bill’s highly creative contributions gave me inspiration. I learned from him that “research ideas do not necessarily come within the 8 a.m. to 5 p.m. work day in the office. The thoughts linger most of the time beyond the office hours and often new ideas come when I am taking a bath, walking alone in the evening, or even in the midnight when I suddenly wake up with the flash of new idea. There is no difference between scientific research and transcendental meditation.”

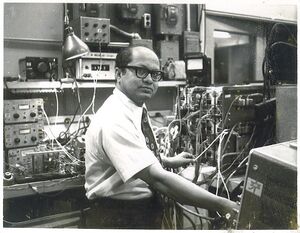

Projects at GE-CRD, 1976-1987

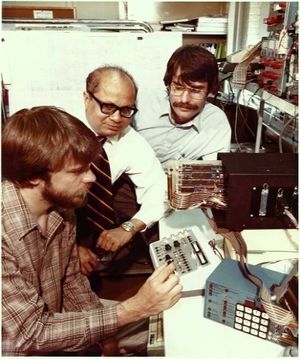

There were three classes of research projects in GE-CRD. The most prestigious were assessed fund projects, which required invention, analysis, simulation (as needed), and laboratory experimentation. These projects were executed by premier scientists with the funds assessed from the company’s product divisions. My first project was an assessed fund project with Bill on ASCI (Auto-Sequential Current-fed Inverter) inverter analysis and simulation. It was an honor to have the opportunity to work with a world-famous scientist.

The other classes were government- and product department-funded projects, respectively. Some projects required bench-type development work, which were done mainly by B.S. and M.S.-level engineers. Of course, engineers like McMurray were exceptions. Externally funded projects, with deadlines for completion, were very demanding. If a project required study of background fundamentals, there was no company time allotted for it. It had to be done in the evening or weekends which we were supposed to spend with our family. Sometimes, meeting the project deadline required a lot of extra hours in office and home. We had to fill up time cards every week for our work. Allocation of company time for the projects was often a difficult task. If I or another researcher spent two hours in library, or three hours for a doctor’s visit, often we had to lie on the time card.

In 1977, my branch manager, Robert H. “Bob” Guess (1923-2010), gave me the freedom to choose an assessed fund project to work on. This was a big surprise. I noticed that most innovative projects terminated only in U.S. patents and IEEE publications. The company encouraged us to write as many patent disclosure letters as possible, some of which were only conceptual ideas. There was a handsome bonus for a disclosure letter if patent application was filed on it. Some of my colleagues working in power electronic circuits had more than 100 U.S. patents.

In the 1970’s GE had received a large contract from the U.S. Department of Energy (DOE) to develop electric vehicles (EVs). This was the first major initiative by the U.S. government after the Arab oil embargo in 1973. Gasoline became very scarce and its price shot up. Suddenly, people realized that the U.S. was too dependent on foreign oil for automobile transportation. Electric vehicles could help solve that problem, at least for limited distance commuting. This was a stimulus to reviving research in power electronics, where thyristor technology and its application markets had become saturated. Thyristor converters had many limitations, of course, and it appeared that this was the end of the power electronics age. Some professionals in this area even started changing their fields.

Our first EV project, ETV1, with a power transistor chopper and dc motor drive (1979) with microprocessor control, was very successful. I became the principal engineer for the EV’s microcomputer control without knowing the ABCs of microcomputers. GE thought that my university background and deep knowledge of power electronics would help me overcome the challenge. Nonetheless, using digital signal processing to develop controls, monitors, and protection was a very difficult subject at that time for a middle-aged power electronics engineer, since the techniques and technologies involved were radically different from traditional power electronics. I had to study and understand thoroughly microcomputers and software, and then design and test the system so that the prototype EV operated satisfactorily before delivery to the DOE by the deadline.

Of course, an experienced technician always helped me. This was the most strenuous time in my career. I spent weekends and many nights at home for the study, and had hardly any time left for my family.

One night, our newly-designed EV drive was undergoing tests on Chrysler’s dynamometer in Detroit. My project manager woke me with a phone call at 1:00 AM one night to say that the drive was having an instability problem while accelerating, and I should come to Detroit in the morning to fix the problem. I lost sleep thinking how to do this. I flew out and solved the problem by canceling the software compensator with an inverse analog compensator, and then connecting an analog compensator in series. Although it was a brute-force method, everybody was happy when the problem disappeared.

Finally, when the project was completed successfully, it gave me tremendous satisfaction, especially when Queen Elizabeth II requested a demonstration in the U.K. for our new EV (ETV I). The last project I did at GE was the interior permanent magnet (IPM) synchronous motor drive using distributed TMS320 DSP-based control, for the ETX-II vehicle that GE designed with Ford Motor Company in 1987.

People thought that it was crazy to use an IPM machine for EV drive, when everybody else used induction machines. Later, the IPM machine-based EV/HV drive became accepted all over the world.

My other important projects in GE included control development of a linear inductor machine for railroad propulsion; a microcomputer-based hybrid (SPWM-SHE) pulse-width modulation (PWM) controller for an inverter; scalar decoupled control of an induction motor; control of a switched reluctance motor (SRM) drive; sliding mode control of induction motor; and maximum power-point tracking (MPPT) control of a residential photovoltaic system. Practical projects like these gave me a lot of experience, and confidence in designing, fabricating, and testing of large systems while gaining more specialized knowledge in power electronics. The experience accumulated from the interaction of projects in different product departments with different organizational partners. Large government-funded projects required contributions from many team members, including the lab technicians, whose help was essential for any project’s success. Such collaboration can be painful for professors who are normally very individualistic.

Occasionally, my program manager walked into my office, and I was happy to show him the excellent simulation result of the drive which I was developing. However, he strongly discouraged simulation studies, withholding his judgment until he saw the actual drive running in the laboratory. “I do not trust simulation results,” was his comment. He only trusted waveforms on an oscilloscope or multi-channel recorder when the inverter was working and the motor was running.

Once a month, our senior laboratory manager Dr. Jim Lafferty invited each of us project heads in rotating order for lunch, where we had to briefly discuss our projects without any audio-visual aids. Suffice it to say that there was no pleasure in such lunches. GE had many product departments, but while the role of the CRD was to give them technology support, the labs’ coupling with them was very poor. Hardly any of our inventions were translated into products. Of course, our large government-funded EV projects were for feasibility studies only.

Career Tracks at GE-CRD

In principle, the company had a policy of “parallel ladder” career paths, where researchers and managers competed on parallel paths for position and salary. However, it hardly existed in practice. Senior managers belonged to an elite class with power, status, and compensation. In comparison, most of the researchers were considered “second-class citizens.” However, the scenario was entirely different when we went outside the company. GE scientists and engineers were highly respected throughout the world. It is mainly their contributions that helped to make power electronics technology so rich today. The IEEE conferences in this area were dominated by the contributions of large corporations, and we were treated like superstars.

GE hired engineers with degrees from all over the world. A doctorate from MIT, for example, could negotiate a much higher salary in the beginning than that of a doctorate from India, like mine. There was a system of “totem pole” evaluations annually, however, where all the engineers were placed in serial rank according to performance, and the salary raise depended on the totem pole position. This means that it was possible for the engineer from India to get a higher salary than the one from MIT after a few years. I heard that the company maintained a secret database for every engineer, in which information related to his marriage, homeowner status, number and age of children, etc. were continually updated. The assumption was that if you were more settled, with less chance of switching jobs, your salary raise would decrease irrespective of your position on the totem pole. Every person had a price tag around his neck, and the question always asked was, “Are you disposable?” This theory of disposability made the scientist’s job more stable than that of the manager’s. During my eleven years in GE-CRD, I reported to about ten managers. This was the reason why some managers tended to be ruthless, in order to show their performance.

Whatever the case, with the totem pole position and the results from the database, the salary raises tended to dry up after a number of years. You received high raises early, small raises later, and then no raise at all for years in spite of great performance. This was the most painful stage in a career. The company always liked to get rid of older, fat-salaried engineers and then hire young, lean-salaried engineers while cleverly avoiding age discrimination lawsuits. If you thought that you were very valuable to the company, however, you could play a trick, and sometimes it worked. You arranged a job interview outside, which was easy for a GE engineer, and got an offer with a higher salary. Then it was time to bargain with your manager, which is, of course, very unpleasant and risky. There was only one exception. In CRD, we had a Nobel Laureate in Physics, Ivar Giaever, who was the show-piece of the company to the outside world. Every year, the company vice-president would go and ask him how much of a raise he wanted.

There was one very good aspect to a job in a large corporation besides the technical projects. The company’s health and pension benefits were very liberal. If you retired from the company after lengthy service, it would bear most of your health costs, including hospitalization, for the remainder of your life. The pension benefits rose almost exponentially with length of service, and you could live a very comfortably after retirement. I found that hardly anybody quit the company.

However, this scenario changed rapidly after “Neutron” Jack Welch became chief executive in 1981. Such liberal benefits were no longer the standard. The managers in the company were under higher pressure to accelerate productivity. Finding the financial resources for a project was normally a manager’s responsibility, but now the researchers were also under tremendous pressure to find funded projects. It was suddenly chaotic everywhere. The company started transferring manufacturing units outside the U.S. to decrease labor costs. The slogan everywhere was “emigrate or evaporate.”

Comparing Research and Development in Japan to GE, 1980s

While the company work was very exciting because of the large projects, and highly prestigious to the outside world, the environment also started changing in the 1980s because of Japanese competition. During a visit to Japan, I found that Japanese engineers and managers were highly disciplined with total dedication to the company work, in a manner somewhat lacking in the USA. The Japanese management style was unique in that it promoted loyalty and friendliness among all in the work environment. While visiting Toshiba Fuchu Works research laboratory in Japan, I found that the top manager worked with the staff in ordinary work clothes. This amazed me. The R&D work in Japanese companies, unlike GE’s, was closely tied with the product development. The additional advantage is that the country is so small, the R&D centers and product departments are coupled and in close proximity.

The result was that Japan began dominating the world in manufacturing power electronic equipment with higher quality and lower prices, and it became a challenge to U.S. corporations like GE. Japanese engineers from Hitachi, Toshiba, and Mitsubishi used to routinely visit the GE research laboratory. Suddenly, the door was slammed in their faces. Once I arranged the visit of Dr. Akira Nabae, professor of Nagaoka University of Technology and formerly from Toshiba Corporation, the most eminent power electronics engineer in Japan. He came to Schenectady, but was denied a visit to the laboratory in spite of prior approval. What a humiliation!

Publishing at GE-CRD

Coming from the university, IEEE publication of innovative work was very tempting for me. However, publications were discouraged, and often delayed until the related patent was approved. There was fear that competing companies might steal our ideas and use them in their products. Instead, writing patent applications were highly encouraged while paper writing was either forbidden or permitted only with a long delay after filing for the patent. Each publication required approval by the hierarchy of company managers, which caused more delays and much frustration. In university, we follow the “publish or perish” principle, where papers are often sent for publication even before completion of the project. In industry, the principle is the opposite: i.e., “publish or survive.” This means that you will survive in your job if you avoid publications. I estimated that I could have almost doubled my publication rate if there had been no company restrictions.

Once my manager called me in his office and indicated that I was wasting company time by writing too many IEEE papers. However, I knew that IEEE papers were extremely important for the long-term growth of my career. While working at GE-CRD, I edited my first book, Adjustable Speed AC Drive Systems (1981), and completed my first textbook, Power Electronics and AC Drives (1986).

This was not easy while working full time in a corporate environment. After I applied for the company approval for my textbook’s publication, my program manager gave me a hard time. His complaint was that I had taken a lot of company time to write it. I struggled to convince him that I wrote it in my home on weekends and holidays with the study door shut against family members, and this was the reason it had taken three years to write. Of course, it is true that I had to use company time occasionally to complete the book.

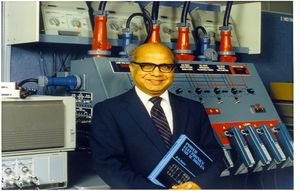

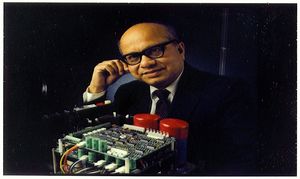

Returning to Academia at the University of Tennessee, 1987-2003

I decided to return to a university career in 1987 after spending eleven years in GE-CRD. Why did I leave? Although I climbed high up the GE totem pole, my salary raises practically stopped in the later years. I needed to reestablish my sense of self-esteem, which was shattered in the corporate environment. At the same time, I found that my expertise in power electronics had improved significantly due to the blending of practical experience with my theoretical knowledge. I also gained tremendous visibility in the world in the power electronics field because of my books and other publications. I thought it was the right time to migrate to the prestigious university job where I really belonged. One fine morning, I got a call from Prof. Jack Lawler of the University of Tennessee, Knoxville, with an invitation to visit the campus. There I was offered the endowed Condra Chair of Excellence in Power Electronics Applications. It was impossible to resist such a handsome salary, along with the initial tenured status that was becoming so rare in the academic community.

In parallel, I also started working as Chief Scientist of the newly established Power Electronics Applications Center (PEAC) of the Electric Power Research Institute (EPRI). Part of my responsibility was to promote power electronics education and research in the United States. In addition to my regular graduate students, I managed to recruit a large number of visiting professors and research scholars from abroad to come and work in my laboratory, funded by their respective governments. All of them were brilliant scholars.

Most of them wanted to do research in the emerging AI (artificial intelligence) techniques, particularly in fuzzy logic and neural network applications. However, it is very encouraging to see that recently AI is picking up in the power electronics literature. We did a lot of pioneering work in the application of AI techniques in power electronics. Unfortunately, the area did not pick up the desired momentum for innovation, possibly because of the general unfamiliarity of the power electronics community with the techniques, and consequently very few industrial applications. Some of our projects included

1) Soft-switched converters for motor drives

2) High-frequency non-resonant link power conversion using MCTs (MOS-controlled thyristor)

3) Fuzzy control of dc and induction motor (IM) drives

4) A fuzzy-controlled wind generation system with efficiency optimization.

5) Neural network–based drive feedback signal estimation and neural control of SVM of multilevel converters

6) Converter fault investigation

7) Automated IM drive control design by expert system

8) Sensorless vector control of IM.

9) High-temperature superconductivity (HTS)–synchronous motor (SM) ship propulsion with multi-level converter

Unfortunately, I was not very successful at gaining major funding for projects from U.S. government agencies. In fact, I hardly tried for it. I loved the university career for its freedom and prestige, but hated being a super-salesman in search of research grants. Instead, I traveled abroad extensively to give tutorials, invited seminars, and keynote addresses. During this period I also completed several other books.

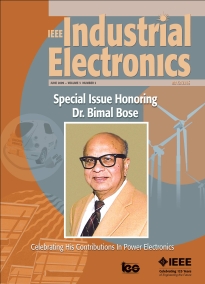

Summary of Key Contributions

I invented the transistor ac power switch and demonstrated it for direct ac-ac power conversion in 1973. This has been recognized as a landmark contribution in matrix converter research. Matrix converters are now used extensively for ac motor drives and high-frequency-link power conversion systems. The IGBT-based ac switch is now universally used in matrix converters. The advent of GaN HEMT (high-electron-mobility-transistor) shows very high promise in this area.

I invented the adaptive hysteresis-band (AHB) current control method and demonstrated an in-voltage-source inverter IPM synchronous motor drive (1989). The method is widely used in commercial DTC (direct torque and flux control) drives and other applications.

I introduced MPPT (maximum power point tracking) control for the first time in a photovoltaic control system (1984) which is now universally used.

I pioneered in the application of microprocessors in industrial control systems. After Intel introduced the 8080 microprocessor in 1974, I developed the first fully functional microcomputer-based electric vehicle (ETV1) control system (1978).The ETV1 was demonstrated before Queen Elizabeth II of England.

I pioneered the application of artificial intelligence techniques (expert system, fuzzy logic, and neural networks) in the control and estimation of power electronics systems, including motor drives. I promoted this emerging technology to the power electronics community in my books Power Electronics and Motor Drives (First Edition (2006) and Second Edition (2020)) and Modern Power Electronics and AC Drives (2001). It appears that AI applications in power electronics will grow tremendously in future.

I first demonstrated high frequency, resonant link power conversion system for ac motor drive (1977) from concept to practice that could operate at programmable line power factor (leading-lagging).

I introduced high-frequency, non-resonant-link, soft-switched power conversion for ac motor drives (1998). The system used matrix converters with ac switches which I invented.

I proposed and demonstrated a high-frequency active filter in the dc link of a voltage-fed converter system (1991) to eliminate electrolytic capacitors.

I published the first text book (1986) on power electronics and motor drives in the English language. Along with its revised version (2001), this has been translated in many languages and used extensively at universities around the world.

I promoted power electronics globally by extensive seminars, tutorials, books, IEEE distinguished lectures, invited presentations, and keynote speeches. I was awarded the IEEE Meritorious Achievement Award in Continuous Education (1997) “for exemplary and sustained contributions to continuous education” for this activity and was elected as a Member of US National Academy of Engineering (2017) with the citation “for contributions to advancing power electronics technology and power conversion and education". Election to the NAE is considered to be among the highest recognitions in engineering fields, and it is a recognition of a lifetime’s worth of accomplishments. Power electronics has now grown as the most important technology for industrial automation, renewable energy systems, smart grid applications, bulk energy storage systems, and the energy efficiency of equipment.

- Bimal K. Bose’s books

Concluding Comments

Coming from a remote village of Bangladesh (then part of India) and being born into a large poor family, it was my dream to see the whole world with my own eyes and make important contributions to the world. I had to overcome mountainous hurdles, step by step, to fulfill the ambitious goals in life and reach where I am today. Although my goals are yet unfulfilled, I often feel that I am the happiest person on earth. Achieving the goals of life requires persistent ambition, courage, and hard work, but when you reach the top of the Himalayan mountain, the mind remains filled with perennial pleasures. My advice to young engineers: have a dream in life and try to realize that dream with hard work. Have a long-term ambition and short-term career goals, with the fire always burning in your mind.