Oral-History:Frank Woods McQuiston, Jr.

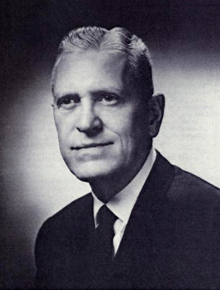

About Frank Woods McQuiston, Jr.

Frank Woods McQuiston was born in Pueblo, Colorado and spent his youth in and around the mining camps of Colorado, Utah and Arizona. He received his B.S. degree from the University of California, Berkeley, in 1931.

In 1938, Mr. McQuiston organized the metallurgical research and development division of Newmont Exploration Limited. From 1941 to 1948 he worked as a metallurgist for Newmont and other western mining operations where he developed several flotation techniques now used in base metal mineral separations in the United States and Africa.

During a leave of absence from Newmont, while serving with the Atomic Energy Commission, Mr. McQuiston spearheaded the use of ion exchange in the South African uranium production program which was later used successfully in the United States and Canada. Earlier he was decorated by the French-Moroccan Government for his role in mill design and metallurgical development of the Zellidja lead-zinc mines.

Mr. McQuiston became a Newmont vice-president in 1964. He holds directorships in O'Okiep Copper Company and Tsumeb Corporation Ltd., and is a director and vice-president of Carlin Gold Mining Company, Granduc Operating Company and Newmont Exploration Ltd.

Further Reading

Access additional oral histories from members and award recipients of the AIME Member Societies here: AIME Oral Histories

About the Interview

Frank Woods McQuiston, Jr.: An Interview conducted by Eleanor Swent in 1986 and 1987, Regional Oral History Office, The Bancroft Library, University of California, Berkeley, 1989.

Copyright Statement

All uses of this manuscript are covered by a legal agreement between the University of California and Frank Woods McQuiston, Jr. dated July 10, 1986. The manuscript is thereby made available for research purposes. All literary rights in the manuscript, including the right to publish, are reserved to The Bancroft Library of the University of California, Berkeley. No part of the manuscript may be quoted for publication without the written permission of the Director of The Bancroft Library of the University of California, Berkeley.

Request for permission to quote for publication should be addressed to the Regional Oral History Office, 486 Library, University of California, Berkeley 94720, and should include identification of the specific passages to be quoted, anticipated use of the passages, and identification of the user.

It is recommended that this oral history be cited as follows:

Frank Woods McQuiston, Jr., "Metallurgist for Newmont Mining Corporation and U.S. Atomic Energy Commission, 1934-1982," an oral history conducted in 1986 and 1987 by Eleanor Swent, Regional Oral History Office, The Bancroft Library, University of California, Berkeley, 1989.

Interview Audio File

Interview

INTERVIEWEE: Frank Woods McQuiston, Jr.

INTERVIEWER: Eleanor Swent

DATE: 1986 and 1987

PLACE: Berkeley, California

I GROWING UP WITH ORE PROCESSING

[Interview 1: 23 June 1986]

Colorado

McQuiston:

I was born in Pueblo, Colorado, in 1904. Pueblo was the heart of the smelting industry for the various gold-silver mines in Colorado, who would ship their ores from the mines to Pueblo. This was the principal industry at that time. It is interesting to note that after the mining operations achieved their own method of reduction, Pueblo became the center of a large steel industry; CF&I Company [Colorado Fuel & Iron] developed it into a large steel production center.

Swent:

Did your father work for CF&I?

McQuiston:

No. My father was the shippers' representative from the various mining companies who needed an umpire to be sure that they got their just returns from the smelting of the ores. Prior to moving to Pueblo, he operated a mine known as the Silver Carbonate Mining Company in Leadville which was at an elevation of 10,300 feet. During his period of operation the mining camp of Leadville became embroiled in a labor dispute between the miners and the mine owners. The mines comprised small areas of very rich ground and in turn had, I believe, fifteen different smelter units because that was the only method of separating the silver from the lead. However, it was a very simple ore to smelt.

Because of the strike in Leadville, which had shut down a majority of the mines, my father, having a short lease and option on this mine, decided he would go to Missouri and round up a crew of hardy miners, which Missouri mines were noted for. He brought back thirty men on the train to Malda, which was the railroad town eight miles from Leadville, and transported his men in wagons with what protection he could get from the local authorities. In the meantime, while he was going to Missouri and back, his remaining crew at the mine built a stockade of two-inch planks eight feet tall around the workings which enclosed mine dormitory, mine mess hall, and, of course, the timber-bolted headframe for working the mine. All the mines in the district were underground.

The opposition of striking miners mounted a Civil War cannon on a hill overlooking his operation and loaded the cannon with kerosene-soaked clothes and some steel pellets for the weight to carry the wads of kerosene clothes. And they fired the cannon and set fire to the mess hall, the dormitory, and eventually caught fire to the headframe, which, as I mentioned, was a wood structure. And then in due time, because they had no water except a small spring for drinking purposes, the stockade burned down. Everything was burned down.

Swent:

Was this your father's own investment?

McQuiston:

Well, they always had some partners.

Swent:

But that would be a major blow, wouldn't it?

McQuiston:

Yes, it would. After the mine buildings and headframe were burned down he left Leadville and settled in Pueblo, Colorado, in connection with the smelters previously mentioned. It is interesting to note at this time that the Guggenheim brothers, who were the founders of the American Smelting and Refining Company, had a small smelter in Leadville and decided that they would buy more smelters because there was no other way of recovering the silver from the mine ores. So this was the birth of one of the largest mining companies in the world, the ASARCO, as it is now called. They were in this business for the next hundred years.

Swent:

Did your father know the Guggenheims?

McQuiston:

Yes. I've forgotten their names, they were the founders, yes.

McQuiston:

At an early age our family moved to Utah in 1910, again because of my father's interest and connections in mining. We lived at Tooele, and then in Sandy, Utah, not far out of Salt Lake City, where I started the first grade.

Swent:

Did you have brothers and sisters?

McQuiston:

I had one brother who was three years older. In Sandy, this little Mormon town, there were only two non-Mormon families: the doctor, his wife, and two sons; my father and mother, and their two sons. So after very few years my mother decided that she did not want her sons to grow up and marry Mormon girls. This was the time of Zane Grey's stories. However, I have had many fine Mormon friends, and strange as it may seem, when we moved from Sandy, with the doctor and his wife and their two sons, to get away from the Mormons, we arrived in Mesa, Arizona, which was a Mormon stronghold.

Arizona, with a Southern California Interlude

McQuiston:

We actually moved to Prescott, Arizona, so that we could enter school, my brother and myself, there. And it was very close to the famous Jerome village, which was the home of the Phelps Dodge Copper Company.

Swent:

And it was booming then, I suppose?

McQuiston:

Yes. The smelter for the Jerome ores was at Clarkdale, where my father again had much business with the smelters.

Swent:

But you lived in Prescott?

McQuiston:

We lived in Prescott.

Swent:

It's a nice town, isn't it?

McQuiston:

Oh, lovely. During this period of early Utah and Arizona days my father became interested in Rhyolite, Nevada, which is in the southern part of the state, and the center of considerable gold, mining. He and other friends such as Clyde Jay, a famous mining executive, built and operated one of the early cyanide plants in the United States at Rhyolite. This was in 1906.

Swent:

Do you want to tell me about the picture [indicates a photograph]?

McQuiston:

This is a picture of Rhyolite, Nevada, dated January 20, 1907, a town of 10,000 people.

Swent:

Oh, it was a pretty big town, then, wasn't it?

McQuiston:

This is the little town that built a home out of beer bottles.

Swent:

Tell me about that!

McQuiston:

Well, there was lots of beer drinking, so the house of beer bottles, or rather what is left of it, sits in the Amargosa Desert a few miles east of Death Valley. In 1908 this town had 10,000 people, two railroads, three newspapers, electric lights, an opera house, a telephone company, and a seventy- five-member stock exchange. Today it has six permanent residents. So my father's idea of building a custom cyanide plant for the treatment of the local gold ores was a sound investment.

Swent:

You didn't actually live in Rhyolite, though?

McQuiston:

No, we just couldn't move around.

Swent:

Your mother and the family stayed put.

McQuiston:

That's right.

Swent:

But you learned from an early age what the mining life involves.

McQuiston:

From Prescott, where I went to the third and fourth elementary grades, we moved to Hayden, Arizona, in 1914. Hayden was a milling town or in a layman's terms, an ore processing center. It was part of Kennecott Copper Company, who had the world's largest copper mine at Ray, Arizona, twenty miles distant by railroad from Hayden. To make a mining story complete, there were the mines, the mill, and the smelter. Kennecott, at that time, did not build smelters. They used American Smelting and Refining Company to smelt their concentrates produced from the mills. This was the case at their large Bingham Pit mines and mills operation; Garfield smelter was operated by ASARCO.

In Hayden it was the same procedure. The mines were some distance, as mentioned, twenty miles away, connected by railroad, operated by the Southern Pacific Company, hauling the ores because of the rugged terrain to the mill, which required a large area for tailings disposal. The mine at Ray was founded in the 1880s but only mined for the high grade near the surface. It was D.C. Jackling, the farsighted head of Kennecott Copper, who recognized that these huge copper deposits, although very low grade, could be mined at great profits by using steam shovels and wagons at that time, and later, trucks.

His chief engineer for the appraisal of the mines, which at that time were Bingham Pit, Ray, and Chino, in New Mexico, was Henry Krurob, a noted mining engineer who examined and sampled these low-grade deposits.

Swent:

Did your father work with any of these people too? Or was he independent?

McQuiston:

Well, no, he worked for Kennecott at that time. My father, again, was interested in the smelting of the mine-mill products, and became an independent contractor to represent Kennecott Copper Company for the shipment of their concentrates to the Hayden smelters.

Swent:

As a boy, then, were you hearing conversations about the mining and smelting?

McQuiston:

Oh, yes, well, at Hayden, when I was old enough to absorb these things, yes.

Swent:

Because now he's in copper, whereas before it was gold and silver.

McQuiston:

And in Tooele it was lead.

Swent:

So you were getting a pretty broad education at home.

McQuiston:

After two years of elementary school in Hayden, my mother, brother, and I moved to Phoenix, Arizona, because he was ready to enter high school, and there was no high school in Hayden. So this was now my fourth grammar school. Sandy, Prescott, Hayden, and Phoenix. In due time we moved back to Hayden and I had a severe accident so I did my eighth grade with a tutor part of the time in the hospital, and part of the time just in bed.

Swent:

Do you want to tell about the accident?

McQuiston:

Oh, not particularly.

Swent:

All right.

McQuiston:

Before the accident I attempted on my own to do a little mining. I got several Mexican boy friends to round up a herd of burros, of which there were many wandering around town, and in the nearby hills, that the Mexicans used for bringing in wood for cooking.

So I took these Mexican boys and a string of ten burros to a mine that I had visited previously with my father, which had some rich lead-silver ore on the dumps. The Mexican boys and myself sorted the ores from low grade to the high grade side, put them in bags, used the burros for pack animals, and packed it down to the railroad at Hayden junction where my father arranged for it to be shipped to the El Paso ASARCO smelter. I didn't make much but I made a few dollars out of this first mining venture.

Swent:

And how old were you at that time?

McQuiston:

I was thirteen.

Swent:

Thirteen years old! Your father must have been pretty happy about that.

McQuiston:

Yes.

Swent:

So that was your first experience in management, also.

McQuiston:

Managing the Mexican kids [laughter]! I graduated from Hayden Elementary School with about twenty-four other graduates.

Swent:

Have you stayed in touch with any of your elementary school friends?

McQuiston:

No.

Swent:

You went different ways.

McQuiston:

And then, to have my hip corrected, which is a misnomer, we went to Los Angeles, and a noted orthopedic specialist put me in a cast after manipulation, without an operation. I was in the cast for six months, attempting to attend high school in Hollywood, where we lived. At a later date we moved to San Diego, where I entered high school.

Swent:

Had your family had a California connection before that?

McQuiston:

None. We went to get a good doctor, because a doctor in Hayden had practically ruined me.

Swent:

So you went down to San Diego?

McQuiston:

We moved to San Diego where I entered high school, on crutches for a while, but out of the cast, and then later I was able to drive my Model T Ford wherever I wanted to go, and became quite active through swimming, sailing, and water sports, which I found, at the doctor's advice, were quite good for me.

Swent:

Your father must have been pretty successful by this time? It sounds as if things were going well.

McQuiston:

My father, in the meantime, due to a severe depression in copper, had gone to Oatman, Arizona, which was a sizable gold mining area. It is strange that copper has always been a metal that was either very good or very bad but seldom in the middle. We used to have a saying in copper mining areas that you were either eating T-bone steaks or burro meat.

Then in 1922, after finishing my second year in San Diego High School, we moved back to Hayden, Arizona, where I became quite a figure in high school, having been the only one who had ever gone to school outside of Hayden.

Swent:

There was a high school in Hayden by now?

McQuiston:

Yes, a good high school.

Swent:

And you were the cosmopolitan figure.

McQuiston:

Although we only had fourteen or fifteen boys in high school, they were all rather outstanding athletes because they had been together for several years in grammar school, and in three years of high school. So our sports activities placed them very high within the state of the class two high schools. In fact, we won the baseball state championship for the class two group. I couldn't participate--only occasionally in baseball--but I was the manager of the basketball, football, and baseball teams, so I became interested in athletics from that time on.

Swent:

It sounds as if you developed your management skills rather early.

McQuiston:

Yes. I was even coach and manager at times when we didn't have a coach. While going to high school in my senior year, I was employed at the smelter in the office as night clerk, whose duties were to check in the afternoon shift at three o'clock, and the outgoing shift at eleven o'clock.

Swent:

What sort of checking in did you do?

McQuiston:

Just checking the employees, the shift, the crew of men who were coming on to work. They worked three shifts.

Swent:

Was there any inspection for stealing high-grade ore?

McQuiston:

Oh, no, not in a smelter.

Swent:

Just marking to be sure they were at work?

McQuiston:

That's right. They had little brass tags that they carried with them, and they would give that tag to you as they passed your window. You would put it in a box with slots in it, so it would be easy to find it again and give it back when they came off shift. And they kept that tag with them. That was their identification.

Swent:

What did you do in between?

McQuiston:

I had my other duties besides checking the crews in and out, a modified form of bookkeeping, but principally, a lot of reading and my best grades ever, in school, were made during that six-or eight-month period that I worked at the smelter. I also worked for a while in the mill. In the early stages of the Hayden mill, that was back in 1912, and '13, and '14, the ores were crushed, ground, and sent over, placed over, vibrating tables which were called Frue vanners, which concentrated on one end, through the shaking and motion of the long belts, which would separate the sulfide copper from the oxide copper, or the gangue waste material in the ore.

At this time flotation was just making its entry into the copper mines. There were many young men employed in the copper mines as engineers, but even more in the mills because they needed chemical and metallurgical assistance in developing flotation. They developed a reagent and named it Rayconite after the Ray mines. Rayconite was one of the early forms of creosote with something similar to xanthate for collecting the mineral. The early flotation cells were like a long hog trough with a canvas filter bottom which air would percolate through and raise the sulfide mineral to the surface where it could be scraped off in the form of a concentrate, [interruption]

Swent:

This is after the war; did the First World War have any influence on you? Were you particularly affected by that?

McQuiston:

No, I was in high school in either San Diego or Hollywood at that time. It affected the mind some, because I remember my mother raised her brother's daughter with us; she was older, very pretty. My mother raised this niece. So the young men used to come to our house to see her, and take her out and all, and I remember several of them going off to war.

Swent:

They were older, of course.

McQuiston:

Yes, they were through college and working there.

Swent:

Usually, during war time metals mining is affected.

McQuiston:

It was, it was booming then, because they needed the copper for shells, for the brass.

Swent:

Then it slumps back.

McQuiston: Then, after the war, in 1922 and '23, there was a severe

copper depression. And the mines curtailed production and reduced employees considerably.

Swent:

That's about the time that you were working as night clerk, then? You finished high school in 1924?

McQuiston:

In 1924, but they still had to keep a certain number of employees.

II THE UNIVERSITY OF CALIFORNIA COLLEGE OF MINING

Swent:

How did you happen to go from Arizona to the University of California?

McQuiston:

On graduation from Hayden High School, I was influenced by the manager of the Hayden milling unit of Ray Consolidated Copper Company and the principal of the high school, both of whom were graduates from the University of California.

Swent:

What were their names?

McQuiston:

Walter Garmes graduated from the UC College of Mines.

Swent:

He was the one who worked in the mill?

McQuiston:

He was general manager of the milling department. There were three units: the mine, whose manager was William J. Boyd, the mill was Walter Garmes, and then the smelter was a different company. And the lady who was the principal of the high school was Lucille Herman.

Swent:

They had both graduated from UC?

McQuiston:

From UC. I have often wondered why they were so interested in having me go to the University of California when just seventy miles away was one of the outstanding mining schools in the United States at the University of Arizona School of Mines. But, anyway, they talked me into going.

A Preparatory Year Workine for Shell Oil Company

McQuiston:

So I came to California for an interview at their suggestion about becoming enrolled. And at that time I decided on a loophole, that if I went to work, which I badly needed to do for the money to go to university, I decided that if I could become a resident of California, I wouldn't have to pay a nonresident fee. So I worked at Martinez, California, at the Shell Oil Company research laboratory for over a year prior to my entry into the University of California.

Swent:

How did you happen to get that job?

McQuiston:

Waiting in line. I had no connection with Shell except I knew that I was going to live at Torme because my father and mother had more or less followed me from Arizona to California and he was working for American Smelting and Refining Company at Selby, which was within commuting distance of the University of California, and I could save some money by living part time at home. I canvassed the nearby industrial plants such as the California and Hawaii Sugar Manufacturing plant at Crockett and also was interviewed for a job at Martinez by Shell Oil Company. They had a large control laboratory for the purpose of determining the different constituents of oil and gasoline from all major oil companies to be sure that the Shell product was equal to if not better than their competitors.

I enjoyed the work very much at Shell, although it was shift work. Meaning that you worked three shifts; at two- week intervals you would change and go on to the next shift. Eventually, I became shift boss which gave me a considerable raise in pay and more responsibility.

Swent:

That was pretty quick to become a shift boss, wasn't it?

McQuiston:

I was a little older than the average student entering Cal. After serving a year with Shell Oil Company as I got ready to go to Cal, I went in to thank the management for their offer of a position which I badly needed to have money to enter Cal with, and the manager was kind enough to offer me a scholarship if I would take chemical engineering at the University of California. Apparently I had had a good record while working at Martinez, but I had no desire at all to become a chemical engineer so I graciously turned him down on the very nice offer.

Swent:

It must have been tempting, though.

McQuiston:

I guess. But you know, when you're young, nothing is going to stand in your way of what you want to do.

Swent:

You had a clear idea of what you wanted to do?

McQuiston:

No, I didn't. I knew I wanted to take engineering, but not any particular subject. I resigned from the Shell Oil Company and registered at Cal the same day I resigned because I had worked a graveyard shift and got off work at seven o'clock in the morning and drove to Cal for my initial registration.

An incident occurred when I was standing in line. Some big old boy who was obviously from a farming area was in tears because he was born and raised in the state of California and yet they had him down as a nonresident. And he didn't have the funds to register at that time, but I feel sure that it was eventually straightened out. I followed in line, and had no problem at all although I hadn't been in California for quite a year and was under age when I started working in California, but I sailed right through the inquiry and seemed to justify my statement that I was a resident, thereby saving considerable money.

Swent:

I'd like to know more about your commuting.

McQuiston:

I'll get into that.

Swent:

I was wondering what kind of car you drove and how long it took you.

McQuiston:

I had a Model T Ford coupe that I had had for many years, and the only reason I could afford it was because I could do all the repair work myself, which any half intelligent person could do on the old Model T Ford because it was so simple. I had it in San Diego when I went to high school there and later drove it back to Arizona and enjoyed the privilege of having a car to help me get around because I wasn't so agile.

Swent:

And then you drove it from Arizona out here to California?

McQuiston:

That's right. And used it to commute.

Swent:

That must have been a long drive in a Model T.

McQuiston:

Oh, it moved right along. Roads weren't good. As I've mentioned, my family moved to Torme, which was the village next to the smelter town of Selby. Again, this was a Guggenheim operation, one of the old smelters. All gold and silver reduction eventually had to go through the smelter in Selby as it was the only one of its kind in the state of California.

Swent:

Were people aware of lead poisoning at that time?

McQuiston:

We became aware of it.

Swent:

When your father worked there, for instance.

McQuiston:

No, we were not aware of it.

Swent:

There wasn't any talk of danger from it?

McQuiston:

I'll come back to that when I'm at work at Selby.

Engineering at Cal

McQuiston:

At the University of California, the first two years in any form of engineering were practically identical because you took subjects giving you a sound base for your junior selection of what your major would be. So I looked at various majors such as civil engineering because I was possibly interested in building bridges, having seen the Carquinez Bridge being erected as I lived right next door with my family at Torme.

And then there was mining and metallurgy, mining geology, and petroleum engineering. Not to mention some side issues such as meteorology and things like that. So the first two years of general courses in engineering prepared one well for the selection of his major interest at the junior level.

I was quite undecided at that time as to what kind of career I wanted to follow. Shell Oil Company offered me a scholarship if I would take chemical engineering and go to Cal with this scholarship. I didn't particularly favor chemical engineering. ASARCO, where I worked every Christmas holiday and every summer vacation while I was at Cal, offered me a scholarship if I would take nonferrous metallurgical engineering. I did not, at that time, think I wanted to work for the smelters as I had seen enough of them in the past.

Swent:

Did you take either of those scholarships?

McQuiston:

No.

Swent:

You turned them both down.

McQuiston:

They wanted me to take these certain courses, and I decided I didn't want those certain courses. And yet I ended up in metallurgy. But I never liked nonferrous metallurgy, that's smelting.

Swent:

So you had a pretty good idea, even then, what you liked and wanted to do.

McQuiston:

Generally speaking.

Swent:

Had you studied chemistry in high school?

McQuiston:

Oh, yes. While in high school, in preparation to going to the University of California, the coach, who knew something about mathematics, taught me algebra and geometry courses so that I would have those on my graduation record. The only thing I didn't have was mechanical drawing, and they had no one to teach mechanical drawing, so I went to Crockett High School three nights a week for a six-months term to study mechanical engineering.

Swent:

This is while you were working at Martinez?

McQuiston:

Yes. My father, at this time, worked for American Smelting and Refining Company at Selby.

Swent:

So your family had moved out here.

McQuiston:

They moved out after I had come out because they didn't think I ought to be, at that age, living alone. So I put aside a considerable, at that time, sum of money to carry me through the first six months or a year at college. And then my grades declined because I had to work and earn money to go to college. Worked my way through all the way, but with the great help of American Smelting and Refining Company because they had always had a job ready for me. The day after I finished school, winter vacation or summer vacation, I always went to work the next day, which is pretty good.

Swent:

At Selby?

McQuiston:

Yes.

Swent:

That gave you some security, then, didn't it?

McQuiston:

Yes, it did. But very little vacation time.

Swent:

Who were some of the professors that you had at Cal that you particularly remember?

McQuiston:

Dean Frank Probert, number one. Hersam, I don't remember his first name, he was professor of metallurgy. And because I was working at Selby, he thought I ought to be giving these lectures instead of him because I knew more about the practical aspects than he did, because I worked in practically all the departments out there; then after a period I had a couple of years of continuous experience. And then there was Carlton Hulin, who was a geologist. And Norman Hines, he used to give Geology 1A. And Andrew Lawson, and "Tucky" [Nicholas] Taliaferro.

Swent:

Were any of these people particularly influential on you in your personal career decisions?

McQuiston:

Oh, then were was Anderson. Anderson was. He taught mineralogy and I liked that very much. I was a little older, you know, and I didn't take so well to some of these things.

Swent:

You did know a lot already.

McQuiston:

Well, yes. And I was older and had a very unhappy youth because of my bad hip. But then, that's another story.

Swent:

You were not too old to get involved in a few high jinx, though.

McQuiston:

No, I had a lot of very close friends in college.

Extracurricular Activities

Working for ASARCO

Swent:

Were you involved in extracurricular activities?

McQuiston:

Yes. I worked that first summer between my freshman and sophomore year as a guard on the armored truck that commuted daily between Selby and the mint on Fifth Street in San Francisco. We transported the bullion bars of silver and gold and brought back impure bars of silver and gold for refining at Selby. We would leave the plant at eight o'clock in the morning, having locked the doors to the cab, which was equipped with bulletproof glass, and we were armed to the teeth with two shotguns, two rifles, and side arms.

We were timed along the route of driving to San Francisco. For example, the first station was a service station who telephoned in to the operator on duty at the switch that we had just passed at, say, 8:48 and then the next one would be something along the highway that was permanently occupied. And eventually we got to the bridge and to the mint.

Swent:

How did you cross the Bay?

McQuiston:

The Bay Bridge. And followed what is now 1-80 into San Francisco and to the bridge entrance and then across and parked at the mint where we unloaded, with their help, the bullion that we brought. The interesting bullion we took back was from the Philippines because they were small bars about the size of a cake of Ivory soap, and they were shipped from the Philippines to the mint, or either direct to Selby but we would pick them up at the mint. Because Selby had an arrangement that the post office would deliver these gold bars, which were small but, of course, very heavy.

Swent:

They had been mailed in the Philippines?

McQuiston:

Yes. Sent by registered mail with a cardboard full of stamps on them. That was from the Benguet and Balatok mines principally. They were the main shippers. I would dream, while we were driving along, because we didn't have too much conversation.

Swent:

How many of you were there?

McQuiston:

Two. The driver and myself as the principal guard. But we didn't talk too much about any consequential matters because we were more or less alert to road blocks or something like that because it was nothing unusual to carry a million dollars worth of gold, which was a lot in those times. That lasted all summer for three months and was very interesting. It was not hard work. We would finish our run and get back to Selby by noon or shortly after noon and then would do some work in the ore sampling department, then go home early.

Swent:

How did you happen to get this job?

McQuiston:

Because I was always guaranteed a summer's job and a winter's job. We had three weeks vacation normally during the year at Cal for Christmas, so I worked during those times at Selby. I, as a pastime, would think, now if I were going to stop this vehicle and attempt to rob it, where would it be? Now, the cab was locked from the inside, and could only be unlocked from the inside. The body of the armored truck was locked with two sets of keys when we left Selby, and could not be unlocked because we had carried no keys with us, until we had reached the mint, where the second set of keys would unlock the body of the truck. So I conceived the idea that the mint was the only place we were really subjected to a holdup, because every twenty or thirty minutes we were timed, and if we didn't pass that place for a check station, then the police and patrols and all would be out looking for us, which happened when we had a flat tire. Then we would be guarded by the highway patrol until we got the tire changed and on our way again. However, they were exceedingly heavy- duty tires and that only happened on one occasion, to my memory.

The place that I selected for the greatest care and personal attention was when we arrived at the mint. We backed down from the street through a very slight decline to an approach with cement walls on either side so that they could unlock the back doors and use their little dollies to take the gold bars. There was a guard for the mint, but he didn't pay too much attention to what was going on because we were checking out our load of bullion, and there was a checker-in for the mint, and then two workmen to unload the bars.

The bars were all in white canvas sacks and they had to stoop over this heavy weight--it wasn't so heavy, they were one-hundred-pound bars, approximately--but the mass weight was very difficult to handle. If it had been distributed over a larger object, it would have been much easier. And that was the one place where we were vulnerable to a successful holdup, because they could have surrounded that, although it was sort of a trench where we backed down. The alarms would have gone off, but it wouldn't have prohibited a very clever, organized theft. So I was always on the alert; I picked a certain place I could stand and I always took my shotgun with me, to the amusement of the mint people. But I was young and dedicated to my work.

Swent:

Nobody ever really robbed you?

McQuiston:

No.

Swent:

Was it just the one summer that you had that job?

McQuiston:

On that job. I worked in all the departments in the smelter.

Other Student Jobs

McQuiston:

While attending the university I had various jobs through the student employment agency they didn't call it an agency; it had some other name--student council or something. I cut lawns, I gave driving lessons, I attempted to survey a subdivision once which was, at that time, still occupied by an orchard. I was only taking surveying, so I didn't last over two days on that job because I didn't know enough about surveying, but I thought maybe I might learn. But the man didn't have the patience to teach me. He wanted somebody more senior that could really help him survey. And to go around all these trees was more than my knowledge and capacity.

Swent:

Where was this?

McQuiston:

In Oakland.

Swent:

Probably it is all built up now.

McQuiston:

Probably, yes. Then I had a job parking cars in the evening at a theater in Oakland which is no doubt long gone. That was a job that lasted from eight until about eleven. When I had all the cars parked and all the drivers of the cars were in attending the theater, then I could do a little studying in the booth.

Swent:

Was it a movie theater?

McQuiston:

Yes. I also had a job for a man, sleeping outside his door on a cot, because he was a sleepwalker. And I would have to set my alarm so I would wake up every hour to be sure he was all right because there was a window in his bedroom that he would never allow to be locked, as he said, "If there's a fire, I don't want it locked." We fastened the local lock on it but nothing very secure. He liked to wander around the house while my cot was outside his door. But that wasn't a very good job, in my estimation, although I worked there for a while.

I taught driving to several ladies who had cars and didn't know how to drive, and that was all right; I was a good driver.

Then at the end of my freshman year, the second semester, I joined a fraternity, Phi Sigma Kappa. If I had it to do over again, I would not join a fraternity. They are too demanding on their own affairs and not enough supportive of better students. But I did enjoy it very thoroughly.

And now we'll move to my sophomore year, where you're encouraged by the fraternity to go out for some activity. Not only encouraged, but told to do so. So I selected the Blue & Gold and was a sophomore manager as they called it. All that meant was your main function was to go around and visit all the class. I had the jump on most of the other sophomore managers because I knew where all the chemical laboratories were. And I would very kindly try to get permission from the professor to visit without disturbing what they were doing and I was quite successful in getting a large number of those students to sign up to buy the Blue & Gold when it was published six months later.

Swent:

This was the annual yearbook?

McQuiston:

Yes. So I served my sophomore year satisfying a fraternity requirement. I didn't get paid for this, but I attempted to work a night shift at Selby.

ASARCO; Hazards of Lead

McQuiston:

I would finish my courses and drive to Selby and go to work at three o'clock in the afternoon and work until eleven. I was a guard, again, because I was a trusted employee. I was a guard in the silver-gold refinery, which was quite a responsibility, although the workmen were old hands at the job and had been there a long time and were considered quite trustworthy. I sat in a room, all glass enclosed, above all working areas, where I could look out, and my room was dark, look out over the workmen and see that nobody was filching a little gold or silver or something like that.

I finally went to my foreman and said, "Couldn't I have a little light up there?" And explained that my grades were suffering terribly because I had no chance to study at night. And he said, "Well, it's against all regulations and security and this and that, but we will fix up a small light that will give you a bull's eye right on a book or something of that nature, and have it in an area where they can't see that you have a light from where they work. Because all of our security is based on being observed from above without being seen." So anyway, my grades picked up after that.

Swent:

How did you drive from Berkeley to Selby? Was the tunnel there then?

McQuiston:

No, no tunnel. It's 1-80. You know, it's just at the entrance to Carquinez Bridge. So it was a very direct route. It took me about thirty minutes the way I drive.

Swent:

You were a fast driver?

McQuiston:

Yes, I was then. Thirty, forty minutes.

Swent:

You were leading a very full life.

McQuiston:

Too full.

Swent:

Did you live at the fraternity house?

McQuiston:

I did at the end of my sophomore year, yes. I also worked there waiting on tables. And I got my board and room for that.

Swent:

Where did you work the summer between sophomore and junior year?

McQuiston:

I worked again at Selby; I had a job waiting for me and my principal occupation was on the wharf.

McQuiston:

There was a long wharf for receiving the overseas ore carriers. My job was to boss a crew of mostly Mexicans and Yaqui Indians which we had four of, the best workers in the whole smelter, I believe. Because they were about six feet two, three, four; slender, but just all rawhide. So I worked on the wharf under the wharf superintendent.

Swent:

Did these people speak English?

McQuiston:

Oh, well, I taught them English and I learned some of their language. But it was a good job. I was outdoors all the time and became interested in the ships that would come in. The first thing they would do, they would throw over lines to the wharf where my men would put them over the--I don't remember the nautical terms anymore put them over the pier piles and then they would immediately put down a shield which would slide down from the vessel because it was on the incline. Slide down with this attachment of string, so that it could be pulled back up, of about twelve, fourteen inches in diameter. And that was to keep the rats that we had on the wharf from getting on board the ship. You know, like this [motioning] and the rope going down and these things would slide down on the end of the string and then they would stop there. And the rats couldn't come up the hawser.

So that was a very interesting job. We received concentrates mainly from Peru, again a Guggenheim operation, Southern Peru Company. We also received concentrates from Cerro de Pasco in Peru. Ecuador and Paraguay had mines that were shipping to us. It was quite a busy place.

The precautions taken for lead poisoning were no doubt adequate around the lead smelters but they were not adequate for lead dust in the sampling department or the unloading department. Our men, the workmen, after they had finished their shift, would take high-pressure hoses, which were around for cleaning--air hoses. And they would blow the dust off their clothes, and in so doing they would blow the--it's quite unusual--blow the galena concentrate, with lead concentrate, into the pores of their skin, where it would eventually enter the bloodstream.

I lost a whole crew who had lead poisoning. This is one of the most horrible diseases I ever saw. I visited three of these men when they couldn't come to work, because of my fondness and their good loyalty to the Selby smelter. I visited them in Vallejo and they had lost their minds, but were not too bad off physically. But that was the end of them. Our doctor was the one that discovered this unusual type of lead poisoning. When we cut the use of the air hoses it stopped. But the harm had been done.

Selby, being a lead smelter, and gold and silver, were always associated together, such as I mentioned some time ago about the smelters in Leadville and in Pueblo. The lead ores containing silver, principally, which is a main mineralogical association, and the lead and the smelting of the lead, gold, and silver were compatible with each other for a method of processing and also refining.

Swent:

What were the concentrates that were coming from South America?

McQuiston:

Lead ores, also from lead mines. With gold and silver content.

Swent:

And bullion from the Philippines?

McQuiston:

That came from cyanide plants in the Philippines.

Swent:

That wouldn't have lead in it?

McQuiston:

That had no lead. See, Selby was a lead smelter but a refinery for gold and silver.

Swent:

Smelting and refining. That's what it says.

McQuiston:

Yes. That's right.

Swent:

And then they also, of course, got concentrates from all over the West; all over California, at least.

McQuiston:

Yes.

Swent:

Anything from Alaska?

McQuiston:

Alaska Juneau [Mine] shipped there for quite a while.

Swent:

So this would have been the summer of 1926, perhaps?

McQuiston:

I entered school in August of '25 and then the working summer would be '26 and then you would go back to school again in '26 and the working summer would be '27.

Swent:

So this is 1927.

McQuiston:

Yes.

Swent:

I was trying to think when the Bay Bridge was built.

McQuiston:

That was the Carquinez Bridge.

Swent:

The Carquinez Bridge was new then.

McQuiston:

Well, I soon gave up any desire of being a civil engineer, because I wanted so badly to see the erection of the final span of the Carquinez Bridge. And I went to my professor who was teaching civil engineering and said that I lived out there and liked very much to see it, and could I be excused from class, which he wasn't attending; he was having one of his teaching fellows give the class. He says, "Yes, you'll get an F in the class." So I went out there anyway, and I did get an F in the class.

Swent:

Did you really! In civil engineering?

McQuiston:

Yes. I didn't attempt to hide from him, and I said, "I live right down there, you could see it. And I followed this construction ever since it was started." Oh, he was mean.

Swent:

What was his name?

McQuiston:

I don't remember. But he taught civil engineering.

Swent:

But not in a very enlightened way. Nowadays they would take the whole class out there for a field trip to watch it. I hope.

McQuiston:

Sure they would. Sure.

Work and Play as an Upperclassman

McQuiston:

In my junior year at Cal my activities were quite numerous, because I had been elected one of the three juniors for the Blue & Gold manager staff. Which was quite an honor and only earned by hard work. I was very active in politics and other activities on the campus, such as being chairman of the junior ball and solo societies, which are things of the past and not to be revered anymore.

Swent:

Do you remember the names of them?

McQuiston:

Well, let's see, there was one in engineering. The society of engineering was Theta Tau, which all engineers of some prominence had to join.

Swent:

That's the equivalent of Phi Beta Kappa, isn't it, for engineering?

McQuiston:

No. It's more social than grades. And Phi Phi, they had a snake for an emblem. And then there was a the Blue & Gold, and fraternity, working, grades, it was quite the fraternity which was very helpful.

You know, stuff that doesn't mean much, publisher society for the Daily Cal. and Raspberry staff. But between the and trying to maintain some semblance of an undertaking. I was made manager of awarded me the board and room, so that

Swent:

It's interesting that everything you've done, you've always ended managing, haven't you? You had that gift right from the beginning, I guess. Plus hard work.

McQuiston:

That's right. It was during the summer of 1928, all geological students had to attend a three weeks field trip under the supervision of "Tucky" Taliaferro. I don't remember his first name, but we called him "Tucky."

Swent:

His name was Nicholas, but everyone just calls him "Tucky."

McQuiston:

Which meant that we established a camp of tents where we slept, and a tent for a mess hall, and we had a cook, Joe Jackson. It was on the San Simeon Hearst ranch, which apparently had a lot of geological areas that the university considered worthwhile studying. This was a very interesting experience, as we were actually in the field doing the mapping, surveying, and everything as if we were full-fledged geologists, which we were not.

At this time I was more or less majoring in geology because I realized the importance of that in any mining operation. You had to find the ore before you could mill it and smelt it and refine it. My over-all grades were not very good, so this was a five-unit course and I worked very hard and got a B which pulled my grades together enough to hold me in line for another year.

Perhaps the most influential of the professors that I came in contact with was Dean Probert, who was a very strict person on the campus but let down his hair on a field trip, which I saw once in Grass Valley. Dean Probert, Carlton Hulin, and "Tucky" Taliaferro. Other professors of distinguished reputation were Andrew Lawson--about whom stories will last forever--and Dr. Louderback. I've had courses from both of those. Lawson had a mean streak In him, more than was necessary. He would lock, at the ten-minute minute, at the ten-minute second after the hour, his assistant would lock the doors and you couldn't get in. And that was fatal, because so many of those and you received an F. Students would be late and they would rattle the door, and try desperately to get in through a window or something.

And one time his assistant wasn't there so he closed the door himself but he forgot to lock it. In came one of our students--you had small classes, probably twenty--came a student, tiptoed; unless you saw him, you wouldn't know he was there, he was so quiet. Tiptoed in and took his seat and opened his notebook and Andrew Lawson said, "That was very nicely done. You didn't disturb the class, you didn't disturb me, and I think you're probably very much a gentleman." But he says, "Nobody comes in my class late! Get the hell out of here!" He just shouted it. I know this for a fact: he threw one of the teaching fellows through the window.

I was taking a required course from Andrew Lawson in my junior year, so I signed up early for my junior year. It was twice a week on Tuesdays and Thursdays and he came for three weeks and we were very careful in recording our notes. Suddenly he didn't come. His little helper was always around locking doors and doing this and that for him--he was just a kind of a servant--but Lawson didn't come any more. So we inquired, we would go to his office, and the secretary would say, "I don't know, we haven't heard from him. We know he isn't ill, but we don't know where he is." Pretty soon the word came back he had gone to China, right in the middle of his class, to look at something he had become interested in.

The next year, after we had had our three weeks, or six lectures, he came, but he didn't come at the first of the year, he came after three weeks. Started in on a sequence of lectures, which was number seven, as if he hadn't been gone for a year. Started right in, and those new students had no notes on the three weeks of lectures that he had given. Some of the seniors had petitioned to get out of that course because he wasn't there. And that was your Andrew Lawson.

The legendary stories about him would take a half an hour to tell. He was in Canada on a geological meeting, and the head of the Canadian geological survey had a daughter, I think she was eighteen or nineteen. And Lawson was past retirement age, he must have been at least seventy, married her, and they had a youngster.

She moved to Silverado, and she became as ornery as he was. Any time you hit a golf ball that went in her yard, and it was not hard to do, she wouldn't let them come in and get it. My son hit a golf ball and it went into her yard and he said, "I'm going over to see if I can get that, I know just where it went, I can see the bush where it went in."

She came out, and she said, "You get out of my yard or I'll have you arrested." She apparently inherited that. She wasn't well, but...

Swent:

Well, that's kind of a problem, but when you live by a golf course you should expect that, shouldn't you? Taliaferro was good-natured though, wasn't he?

McQuiston:

Oh, he was a great person. Very sympathetic and I could learn more from him. I knew Norman Hines very well, because I had a source of what we called lightning whisky.

Swent:

Oh, this was prohibition time, wasn't it?

McQuiston:

Yes. It was called lightning whisky out in Pinole, where they made it. And he was one of my customers. Somebody had told him, "Well, Mac gets a gallon of whisky once in a while and dispenses it around to his friends." He asked me if I could get him a gallon of whisky, and I said, "Sure."

Swent:

Did you have to supply the bottles?

McQuiston:

No, they came in a gallon jug. Nothing less than a gallon.

Swent:

You mentioned Anderson the other day, also. Wasn't there a teacher named Anderson?

McQuiston:

Yes, Andy Anderson. He was a mineralogist. He was a friend of mine; he went on to be quite a big person in the U.S. Geological Survey. He never went into actual mining operations or anything.

That's why we had such a high regard for Carl Hulln, because he was still a consultant to Potosi and Pachuca. And also Randsburg. So he had a lot of practical experience. He became quite a good friend; I saw him after I had left college. I would drop around to his office and talk with him and tell him what I was doing and some of the mines I knew. He was very interested.

Now we're in the junior year where we had to go to summer camp down at San Simeon. It was awfully hard. Then I came back and worked at Selby. At that time they hoped that I would stay with Selby or stay with ASARCO, so I never had the same job twice, although I had experience. The job as guard on the armored truck, I don't see that that was very much experience but it taught me to be careful. Then I had a job working a night shift running a reverberatory furnace. It was a very boring job because you just looked at the temperature and the fire control and then you had to unload the furnace just once a shift. So I could sit on the steps and I could go to sleep. As soon as there would be something wrong with the fire, because it had to be just right, the change would wake me up just in a minute.

Swent:

You must have been awfully tired a lot of the time.

McQuiston:

Well, yes, but when you're young, I was pretty strong at that time.

Swent:

So then you started your senior year.

McQuiston:

I took a broad outlook of what I was doing at the university so I decided that my choices would be either geology, which I wasn't equipped for because of my bad leg, or metallurgy. I wasn't interested in mining engineering because I realized that I would have to serve an apprenticeship underground, doing a lot of underground work. I was more interested in either geology or metallurgy, and they were of course entirely separated subjects. No relationship, none whatsoever. Mining and metallurgy there is, and mining and geology there is, but not those two. Now I had grown up in the mining area, so I knew many people who were dedicated to their work, but I thought, what about all these people that took mining and then went into real estate or brokerage houses, or something like that. So I gave considerable thought to those two specialties which covered the mining field. I could go into any part of the mining field with those two backgrounds.

Swent:

Was mining a very popular field at that time?

McQuiston:

It was. Yes, everything was prosperous.

Swent:

Were you aware of Hoover at that time? Was he any influence?

McQuiston:

No. He was in Washington in '28.

Swent:

That was when he was elected, but had you known of him as a mining person?

McQuiston:

No. Lawson had a counterpart, Willis, at Stanford who was quite literary, wrote a lot of professional papers; he was a great specialist in earth tremors, earthquakes, and things like that. Lawson would say, "Any time a professor doesn't know anything, like a friend of mine at Stanford, he writes a book on it."

Swent:

What about Plato Malozemoff; had you run into him at this time?

McQuiston:

Just casually; he was a straight A student, and I was strapped, and he didn't work.

Swent:

Did you overlap at Cal?

McQuiston:

Yes. We were there.

Swent:

But you weren't friends?

McQuiston:

No. I was in geology more and he took straight mining engineering.

I knew him, not well, because he was a chess player and I was a playboy to an extent. And I was with the athletes. We had quite a few of them in the College of Mining. I think it would be nice to mention that Andy Miller was the center on the football team; Fran Fredericks was in geology and was a crew member of the famous 1928 world championship crew. And there was Dusty Rhodes who was a big seed tennis player in an international competition. These were all very close friends of mine, because I was interested in sports. I couldn't participate, but I could be friendly with those who did. A man named John Coke, who was in mining engineering, was a Cackle on the football team. So we had a pretty good cross section of athletes.

So I guess that brings us up to the fall of 1928. I had not intended to go to my senior year; however, I was the only one who knew it. I had completely run out of funds, although I did have my Blue & Gold appointment. I was appointed manager of Blue & Gold, which paid $120 a month, which would have taken me very nicely through my senior year. That was a paying job, you know, because there was a profit on publishing the Blue & Gold. And I thought, well, that is fine. I can now make up for some of the things because as a manager I've got three junior managers to do the leg work and all I have to do is make the management decisions.

Lo and behold, my present wife, the only one I've ever had, was elected vice president of the student body for 1929, her graduating year. I did not know her. She was a member of Delta Gamma sorority. I knew other DCs, but I didn't know her. And unbeknownst to me, she spearheaded a movement whereby they cut the salaries with the student council, cut the salaries of the Blue & Gold editor and manager, and the editor and manager of the Daily Cal. So that was cut to $60. And that wasn't enough money for me to go to school because I was no longer manager of the fraternity; I was president then. I just didn't have the funds, and I didn't see how I could work because if I was going to stay, Blue & Gold took my attention away from work. I just couldn't do both, and I wouldn't do any job half way.

So I thought it all over very carefully. No one knew that I wasn't registered. Even my fraternity brothers, the closest ones to me, never knew it. I pledged the 1929 class of neophytes into the fraternity, and then I figured I had accomplished enough in getting them on their way and I left and went to Arizona to get work, where I knew I could get a job. I didn't want to go back to Selby; that was right in the neighborhood and I wanted a clean break.

So I went down and worked in the mill at Hayden, Arizona, for a while under the direction of the man who talked me into going to Cal, Walter Garmes. Then I went to work at the smelter. Although it was a different kind of smelting--this was a copper smelter--! had had lots of smelting experience so I went to work at the smelter in sort of a fill-in job position because I could do most anything around the smelter, from running the big cranes overhead to doing anything.

Swent:

Where did you live at this time? Did they have boarding houses?

McQuiston:

I lived at the guest house at the smelter. My uncle happened to be the manager. So he allowed me to live at the senior men's dormitory.

Swent:

Was his name McQuiston also?

McQuiston:

His name was Riser, Charles Kiser. My mother's brother.

Swent:

Did you know at that time that Fran was responsible for cutting your pay?

McQuiston:

No.

Swent:

That came out later; you married her in spite of it.

McQuiston:

To get even.

Swent:

[Laughter] You'll never let her forget it? She thought she was being efficient, I suppose.

McQuiston:

Well, she was. They didn't need that money. Then I stayed out of college that year. That would be '29 and I came back and reentered in 1930.

Swent:

The Depression had hit by now?

McQuiston:

Partially. The bad years of the Depression were '31 and '32.

Swent:

But you were still okay?

McQuiston:

I had had all my years 's work in, most of a year's work. And I could live very cheaply and save a lot.

Swent:

You drove your Model T back to California?

McQuiston:

Oh, no. That was no Model T. That was a Model A then. I bought the first Model A coupe that came into Berkeley. I knew the fellow, he was an old fraternity brother, who owned the Golden Bear Ford Motor Company. So I used to visit with him, you know, looking to turn in my car. Well, it hadn't come in yet, hadn't come in yet. So finally they did come in. I had to go down on a Saturday, and here it was on the floor. So I talked to some of the men and I drove it off the floor and I said to him, "I've got it now." So he let me keep it. Oh, that was a fine car.

Swent:

Yes. Did it have a rumble seat?

McQuiston:

Yes. That car--turn over on its side, get a couple or three men, we would ride it back up again. I always carried extra oil, would put oil in the thing and then drive off. It would do anything.

Swent:

You see them still.

McQuiston:

Yes, there's one here [Villa Marin, San Rafael, California].

Swent:

They were wonderful cars. So that's what you were driving back and forth.

McQuiston:

That's right.

That was a '29 model but I think I got it in '28, I'm not too sure. But it was the first one of its kind in Berkeley. Oh, I had it a long time, too. Drove it thousands of miles. So then I came back to school in 1929, registered for my classes and picked up where I had left off a year before.

Swent:

Back to the fraternity?

McQuiston:

Yes. I've forgotten how I paid my bills there, I guess I had enough. I wasn't the manager and I wasn't president. But anyway, yes, I had enough to pay my way.

Swent:

Now you switched from geology?

McQuiston:

No. I still had geology, and metallurgy, and all the engineering courses. But I met Fran [Frances Haseltine] and became somewhat interested and then more deeply interested; and maybe it was the intrigue of what she had done with me. She was taking a postgraduate course to get her teacher's certificate. This was in '29 and '30. And she had an apartment across the street from the DG house, which was just around the corner from the fraternity. So I started taking her out.

Swent:

I don't know how you had time with all these other things.

McQuiston:

I had a little more leisure at this time because of having worked for a year and saved.

We were still having field trips. We had a field weekend for geology and went to Mariposa. I was manager again; I should have opened a tour office, shouldn't I? I was manager of the group which comprised, oh, twelve or fourteen juniors and seniors in geology.

Swent:

Were there any women in your geology classes?

McQuiston:

All men. And Tucky Taliaferro was again our field professor. We were staying at the local hotel, boarding there, through arrangements that I had made for all of us. We arrived on Friday; most of them had some means of conveyances, it was up to them to get there. I didn't have to arrange a bus or anything like that. We met at the hotel to spend a day in the field at Mariposa, which had very interesting geological structure. We probably walked miles that day studying the outcrops and whatever Tucky wanted us to look at, and I, as manager, felt I ought to have some kind of entertainment for these boys at night. So I asked Andy Miller, Fran Fredericks, and a fellow named Ross if they would like to have a little libation. And they said, "Where would you get any in Mariposa?" And I said, "Well, I'll make it up."

So I took some lemon extract, some Virginia Dare wine, that was a cooking thing, I don't know whether you ever heard of it. It had a little alcohol content, and I mixed those together and something else, and so we had a little snort of this brew because there was no way I could get anything else. I did bring a bottle of wine with me, though, and that made this punch. And so we had enough to revive our spirits after a heavy day in the field.

There was a local circus in town. So we thought wouldn't it be fun to let that mangy old lion out. He probably has lived there so long that that's the only home he knows and he wouldn't go far and it would just really cause a lot of fun. And we stood there and looked at him; he didn't even get up off the floor and growl or anything, even if you poked a stick in at it. So we decided he didn't have any teeth, because we noted bowls like mush for him to eat. So he didn't have any teeth. And it was just a two-bit side show, was really what it was. So we decided, why not let the lion out to run around a little bit, create a little excitement. About that time we were working on the hasp on the door, and one of the attendants of the circus saw us. They had a battle cry which has been with the circuses for a hundred years; they would call, "Hey Rube!" And that meant something was going on and they all assembled with their picket stakes ready to do harm to anyone that was doing harm to their circus.

These circus attendants came up and they saw Miller, who was about six foot three, and Fran Fredericks, who was six feet four, and I was around six feet then, and Ross--he wasn't big but he was husky. So they decided that they wouldn't have a fight with us but they would talk us into leaving. So we did; we decided there wasn't anything at the circus to interest us. We went by the courthouse, the famous Mariposa [County] Courthouse.

Swent:

That's a very historic building.

McQuiston:

There was our Blue & Gold stationery heading, see. [Shows stationery). The '28 crew. That was the theme of the book. The clock tower two-story white frame building built in 1854. It's the oldest courthouse in California. So walking back to the hotel or just around town to see what Mariposa looked like, we walked by this courthouse. We decided my, that would be interesting to see what made the clock tick. So 1 being the lightest of the men that were there, climbed up, it was two stories, you see up here [shows photograph], climbed up to the second story here on the drainpipe. So I went up hand over hand on this drainpipe. You know, the drainpipe comes up like this, then it goes around over the eaves and then back again [motioning]. And just as I got out there to the eaves the drainpipe started pulling loose from the side of the building where it was anchored. So I thought, this is going to be a crash when I land, because I was two stories up--and here were the football player and the crewman down below dancing around, you know. And I never even hit the ground. They caught me. Because you see, it was kind of slow as each one pulled away. So they caught me; there was no problem.

Swent:

You weren't hurt?

McQuiston:

Not a bit. Then, in looking around, we found one of the lower windows open; it wasn't latched. So we all four entered this courthouse room, the chambers. And we decided to get up to the clock. The clock was our interest, not the chambers or anything. We weren't going to be destructive. So we finally found a ladder that led up to this area here and it was rafters like they have on any building or house; it wasn't floored. But they had planks that you could walk on.

So we walked from the back to the front and got up in the clock tower and were working to get some of the hands loose from the clock itself. Andy Miller had taken out a little piece of wedge steel about an inch by a half which held the bell clapper into the frame so that the bell would ring. Unthinkingly, he dropped that in his pocket. It had nothing to do with the hands but in attempting to get two of the hands off, why, we were fairly cumbersome and broke them, broke two hands.

So we decided we had enough. So we all went back to the hotel, but before we entered the hotel, we buried the hands in the yard. We were smart enough to do that because we knew that they would be missed. And who would they suspect but this field trip party?

So that ended that night and we went on the field trip again the next day. When we came in, there was the sheriff waiting. And he said, "Who has this room down here?" Andy Miller said, "Well, I'm there with Frank McQuiston." So he brought a pair of pants out and he says, "Are these yours, Mr. Miller?"

Mr. Miller says, "Yes."

He says, "What's this little thing from the bell clapper doing in your pocket?"

"Oh," he said, "I don't know how that could have gotten there."

He said, "Are you sure you fellows didn't put it there?"

Well, there was no use denying it. And he said, "We have all the evidence that there were several of you involved in this episode. You know, that clock is our pride and joy for not only the little town of Mariposa, but for Mariposa County." And he says, "You have committed a very serious crime."

So Tucky Taliaferro, he was there too--they had all of us--and he didn't say a word. Oh, once in a while he would look over at us and shake his head and grin a little bit, you know; nothing bothered him too much. So the sheriff said, "You're going to come with me, Miller, but it would go easier if you would name the others that were with you."

And we had decided that I would take the blame because I turn my foot out due to the hip when I walk, and I said, if they're going to get anybody, they're going to get me because they can see my footprints on the dust, on this plank that we walked down where my foot is a little sideways. I said, "They'll pick that up right away." Well, they didn't. They didn't see that at all. So it was all agreed that I would take the blame and say, "Well, it was me." Because they had had the evidence. But they caught Andy with that bell clapper piece.

So Andy said, "I was the only one, I just couldn't sleep, and I got up and I got in through the back window."

And they said, "Why would you pull the drainpipe down?"

"Oh," he said, "I was just testing my strength; you know, I'm an athlete and I was just testing my strength."

And the sheriff said, "There had to be two of you because we know that that was pulled off from the top, started from the top down."

Andy said, "Maybe there was somebody, I don't know who it was, though. Didn't recognize him. Nobody was involved but me." They couldn't change his story.

So anyway, they put Andy in jail that night. So the students were leaving the next morning; this was Saturday night. We had had our two days of field trip, so Taliaferro said to me, "Frank, you've got to stay. You're the manager." And he said, "We're through as far as managing a field party goes but we're all going; no use us staying here."

McQuiston:

So I phoned, this was Saturday, and I phoned Andy's brothers, two of them, and I phoned an ex-football player that we both knew down in Merced, trying to raise money. I said, "We might need a fine of as much as $300 or $400, and I haven't got any money." I took up a collection from students that were with us and raised $100 from them on loan. So I had that, and I had maybe $30 or $40 of my own and I said, "We haven't got very much, Andy. How much have you got?" He said, "Five dollars." I was talking to him in the jail. I drove over to Merced the next day and his brothers came up and met me.

They were kind of rough, tough characters like Andy. I said, "Don't you come up to Mariposa because you can't do any good for us. You give me your money." So then I went to see this great football player for Cal and a good friends of Miller's. By then I had about $500 between Andy's brothers and our own and this and that.

Swent:

He was in jail for several days then?

McQuiston:

No, I did this on Saturday. Because I phoned and got everything arranged so that I could meet them. We got the money together, and I went back and talked to the sheriff. He was getting a little suspicious of me and he said, "Why are you so interested in this?" I said, "I'm the manager."

"Oh yes," he said, "I did hear your professor say that you would have to stay on and take care of anything."

And I said, "Yes, I'm the manager. That's why I'm here. Because he was one of the party and it's up to me to do anything I can to help him out."

"Oh," he said, "I understand that now." He was still suspicious of me for some reason or other. Every once in a while I knew too much about it, see.

McQuiston:

Then the trial came up and on Sunday they started coming to town from all the outlying districts in wagons and on horseback, and some of them walking, and then old automobiles; there weren't too many new ones up around there. They came to witness this man in jail who had defaced their loved clock. So I mingled around with them, they didn't know who I was, so I mingled around town and went and talked with some of them. Fortunately there were no saloons. Talked to them, and they said, "You know, I don't think hanging would be out of order here." Well, of course, that was talk; the sheriff would never have permitted that. But anyway, they talked; they said, "then we ought to demand--maybe a ten-year jail sentence would be about right. Penitentiary, no jail. Penitentiary. We don't want him here in our jail. I wish we could get him out and beat him up or something." Oh, it was a rough element there for a while. And his trial was the next day. And it had all gone very quickly.

So I found out who the judge was, this one right here, Judge Scott [shows picture]. And I went to see him, and the sheriff let me take Andy with me. I had won the sheriff over a little by then. I think he was suspicious of me; he said, "I hate to see this Miller get all the blame because I know there were more of you." And I said, "Well, there probably were, they're a rough lot, these students at the University of California."

So anyway, he said, "I'll let you take Miller to the judge's home; the judge isn't going to come up here because he doesn't like this mob any better than I do, so you can take Miller to the judge's home, and I'll see that you get there." So he drove us in an old Ford that he had.

And Miller had such an open face and nothing bothered him, you know. So he just exuded good fellowship and he talked to the judge. The judge said, "You know, I kind of like you, Miller. You tell the truth. You're not telling all the truth and I don't hold that against you because we know that there were more involved. But you're man enough to take the whole blame. Even if it's a jail sentence."

Andy says, "Yes, I'll never say that there was any more than myself involved, because then I would have to give names."

And the judge says, "That's quite a commitment."

I was talking a blue streak, whenever I got the chance, about what a fine character he was. He was anything but a fine character [laughter]. But I said what a fine character he was, and his mother was a widow and she had raised these three boys, and on down the line making it up, because I didn't know much about his history. Except we were very close friends.

So the judge said, "I'll tell you what I'll do, now. I don't want to make this into just a farce, so I am going to levy a reasonable fine, and I will sentence Miller as I see fit, and the fine will be $150." Oh, boy, I almost fell on the floor because I had all this other money with me. I had about $500 by then. And here's the receipt: [reads receipt] "Andy Miller, the defendant appearing on this charge pleads guilt," (because he was!) "therefrom he is fined in the sum of $150. Fine paid. Justice of Peace, Mariposa County, W.A. Scott."

Swent:

What was the date on that?

McQuiston:

That was April 5, 1930. So he said, "I'm not going to put you back in jail now; there is no jail sentence," he says, "I've wavered that." But he says, "You know, I have to face these people. So you get the hell out of town."

So I had to go back to the hotel and check out and get his things and my things. The judge said, "He can wait here if you want." So the sheriff took me to my car and I went to the hotel. The sheriff was in on this then. He said he didn't want to be, but he couldn't help but be, because he didn't want Miller to escape. He didn't know too much about it. So anyway, we went to the hotel, and I got my things and I checked out, because I had slept there the night before, and went back. I put Miller in the rumble seat and he was big; he was six feet three or four, big man. Away we went. Never even turned around and looked back. I put Miller in the rumble seat so that nobody could recognize him.

The newspapers all had here's the Oakland Tribune. They had a picture of Andy Miller in his football uniform bending over a clock with the face of the clock the end of the football. They just made a farce of it, and that's what made the Mariposa people so angry. See, here's a story of "Mariposans Wait in Vain for Trial of the U.C. Gridder."

Because they stood out waiting on Monday morning, waiting for the trial to take place.

Swent:

And he was long gone.

McQuiston:

We were just about in Berkeley then; we were to Berkeley. Then this is the Oakland Tribune. I think this came out of the Sacramento Bee. Because he was a noted football player.

Swent:

Did they ever find the hands?

McQuiston:

We showed them. I didn't; Andy did. He took the sheriff and he says, "The hands are buried right here." They dug them up and they were all right. They eventually repaired it. They were broken off right there [shows picture]. They eventually repaired them. Here's our summer camp [shows picture].

Swent: