Milestones:Polymer Self-Regulating Heat-Tracing Cable, 1972

- Date Dedicated

- 2019/08/28

- Dedication #

- 199

- Location

- Redwood City, California

- IEEE Regions

- 6

- IEEE sections

- Santa Clara Valley

- Achievement date range

- 1972

Title

Conductive Polymer Self-Regulating Heat Tracing Cable, 1972

Citation

In 1972, Raychem Corporation patented and began producing the first commercially successful electric self-regulating heat tracing cable. The conductive polymer in this cable revolutionized the temperature maintenance of process piping, which has had major applications in refineries and chemical plants, and made freeze protection of water pipes simple and energy efficient. By 2008, the firm had manufactured and sold one billion feet of this cable.

Street address(es) and GPS coordinates of the Milestone Plaque Sites

- Site 1: nVent, 899 Broadway, Redwood City, CA 94063 US (GPS: 37.486425, -122.210763)

- Site 2: nVent, 2501 Bay Rd, Redwood City, CA 94063 US, (GPS: 37.484574, -122.208725)

Details of the physical location of the plaque

- Site 1: On the wall of the lobby entrance.

- Site 2: On the outside of the initial development work site, by the entrance door.

How the plaque site is protected/secured

- Site 1: Open to the public 9am-4pm on weekdays.

- Site 2: Protected by a security gate, but not publicly accessible.

Historical significance of the work

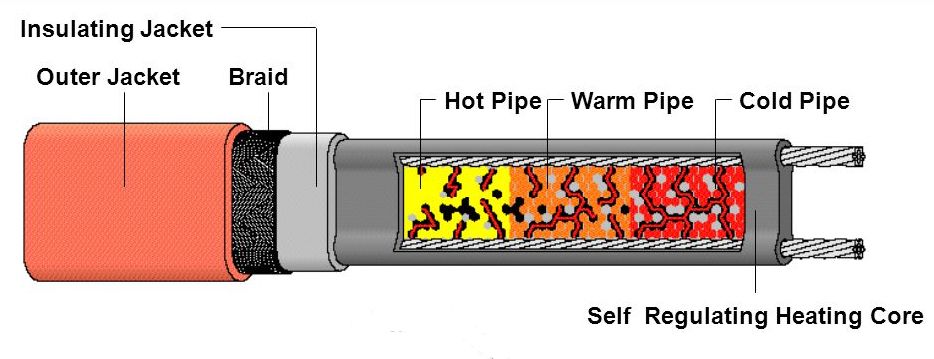

Electrical heating has many aspects including less energy use and tighter temperature control that make it the choice for heating process pipes and freeze protection. Two notable deficiencies are corrected by the parallel circuit self-regulating heaters invented by Raychem in 1972. The heaters are cut to length in the field and won’t easily burn out unlike constant wattage heaters. Historically electrical trace heaters were constant wattage series circuit and the resistance had to be factory determined and fabricated. The key electrical achievement is making a parallel circuit heater by putting a nano carbon black matrix in a polymer between bus wires making a distributed semiconducting positive temperature coefficient resistor. Specific carbon blacks and polymers create a resistance path between the bus wires and the polymer matrix expands through the polymer’s crystalline melt temperature, separating the carbon paths. Thus the resistance goes up. At each section the temperature of the polymer controls the expansion and one has essentially an infinite number of “thermostats” controlling that segment of the circuit. A key for repeatability is radiation crosslinking the polymer so when the matrix cools back below the crystalline melt temperature, the resistance goes back down to original resistance allowing more current to flow and the I^2R (current squared times resistance) heating. The picture below shows an illustration of the process.

The idea of conductive polymers was in its infancy and researchers at Raychem looked at silicones and polyolefins as a possible matrix with carbon black infused into the matrix for conductivity. Radiation chemistry was critical to the repeatability of the heating cooling system as shown in the IEEE paper in this package. The circuit was elegant, parallel wires with a positive temperature coefficient matrix between the wires. What you had was basically a distributed temperature sensor controlling each section of the heater independently. The product was also cut to length in the field. The solution in 1971 for heating pipes was MI Cable which was manufactured to a specific length in a factory. As one would expect, the field as built piping was never quite the drawing estimates and returns for a different length were common. Today the vast majority of electrical trace heating is now done by self-regulating heaters with over 10 manufacturers all over the world making this type of heating cable. By 2007, over a billion feet of the self-regulating heater was manufactured in the building proposed for the installation of the IEEE Milestone Plaque.

Obstacles (technical, political, geographic) that needed to be overcome

Conductive polymer PTC (Positive Temperature Coefficient) tests were made by loading polymers with conductive elements, usually metal powders or carbon black. The resistance change was one way, the resistance went up and never came back. This was solved by radiation crosslinking the polymer which "pulled" the polymer back to the original shape when the temperature decreased. Radiation crosslinking was the secrete.

Features that set this work apart from similar achievements

No conductive polymer had ever been able to cycle to different temperatures and return to its original resistance.

Significant references

See Supporting Materials

Supporting materials

One of first self-regulating patents

IEEE Transactions Paper, Lardear

Market forecast showing Self-regulating is the most used electrical heat tracing

IEEE 1972 Self-Regulating Paper by Oakes and Sandberg describing Technology

Press Release for 1 Billion Feet

Heat Tracing Technology Background