Lenses

This article was initially written by Robert Woods, ASME Fellow. This article contains material published in Mechanical Engineering Magazine Oct. 2006. Copyright 2006 American Society of Mechanical Engineers

At some point in any scientific endeavor it becomes necessary to bring philosophy into contact with the real world. The tools for doing this are the scientific instruments that can be used to perform critical experiments. These instruments are tangible hardware, not abstract thought. The theoretician is thus, sooner or later, at the mercy of the instrument maker.

In the case of astronomy, instrumentation has come to mean better and bigger telescopes. Today, the instrument makers include the thousands who contributed to the Hubble space telescope and the thousands more who are working on the Webb telescope. In the early days, the astronomer depended on the craftsmen who fabricated the astrolabes that gave numerical precision to naked-eye observations.

A clean break in the path between the naked eyeball and the present-day satellite-borne engineering marvels occurred in the 17th century. It was more of a change in paradigm than anything that will ever be revealed by satellites, and the hardware that did it was a few grams of glass- wielded with genius by Galileo Galilei.

In 1609, Galileo published the results of observations he had made using a primitive three-power telescope. At a stroke, he removed man from his previous place at the center of the universe; astronomy left the realm of superstition and became a real science. And the revolution was sparked by a few crude lenses fabricated with tools made in a renaissance machine shop. Manufacturing technology redrew our view of the universe.

Telescopes Pave the Way

The story of progress in early astronomy is the history of lens making for telescopes. Advances were initially confined to increasing magnification. Later, better resolution became critical. Each refinement in lens quality led to another discovery- the lunar mountains, the Milky Way, Jovian satellites, Saturn's rings. The list grows today with Hubble's observations.

Having Galileo's work as catalyst, many natural philosophers became involved in advancing the science of astronomy, which meant advancing the technology of optics. Researchers brought with them knowledge of physics and mathematics, which had previously been only of academic interest. When enough of those philosophers became involved, the scientific revolution had begun.

Accounts of astronomy in the 17th century typically describe complete telescopes. Lenses are mentioned, but attention is rarely given to the methods that produced them. Shaping lenses involved increasingly sophisticated use of primitive tools, all of which were some variation on the basic lathe.

The use of rotating equipment was an important innovation in lens making, although it is possible to grind lenses entirely by hand and, in fact, that was done in the earliest stages.

It is no t known how long lenses have existed. It is possible that Egyptian statues dated to 2600 B.C.E. were the earliest examples. Some statues have remarkably lifelike eyes, which incorporate lenses that may have been hand ground or turned on primitive lathes like those that were then being used to turn axles. The earliest clearly documented reference to lenses - burning glasses, in that case - occurred in The Clouds, a satire by Aristophanes dated 424 B.C.E.

The details on ancient coins and jewelry have led some authorities to guess that the magnifying glass was an aid to fine work dating from a very early time.

Primitive lenses were widely used in eyeglasses as early as 1299. Production methods were crude and the only quality control was in the hands of the ultimate user. The buyer picked through an assortment of lenses and chose whichever helped his vision. Even with this background, it was not until 1608 when, in Holland, the telescope was reduced to practice. A citizen named Lipperhey applied for a patent on a "seeing tube." Galileo became involved only a year later and the revolution was under way.

Da Vinci in the Lead

The tools for lens fabrication went through several developmental stages. As seems typical of mechanical innovation, we find that da Vinci got there first. Around 1500, he sketched a machine that would grind a number of spherical convex lenses at the same time. It does not appear that he ever built such a thing, although he identified the fundamental aspect of lens technology: Every lens is composed of spherical sectors.

During the first days of the 17th century, lenses were ground on a primitive hand-operated lathe. The operator tried to form a lens contour by comparing it to a metal gauge that had an edge cut to match a compass-scribed arc. The approach was soon abandoned in favor of a more sophisticated technique similar to that used today to produce ball bearings. When two surfaces are ground together under the proper conditions, they automatically assume a spherical shape.

With bearings, initially rough spheroids are worked into very precise spheres by many random passes between a pair of grinding disks. A similar approach is used in the Orient to produce the familiar crystal ball. Initially rough crystal spheroids are hand-ground against equally rough tubes. Both assume spherical surfaces by a process that amounts to successive approximations.

Laps and Batons

When freehand lathe grinding was abandoned, the process that replaced it used a series of turning operations in which tools rather than the lens itself were lathe turned. Lenses were produced by grinding them against a metal tool called a " lap," which had been produced using a lathe. Convex lenses required a lap having a portion of a hemispherical cavity. A male form was used for concave lenses.

The laps could be made from any metal, since hardness was not a major factor.

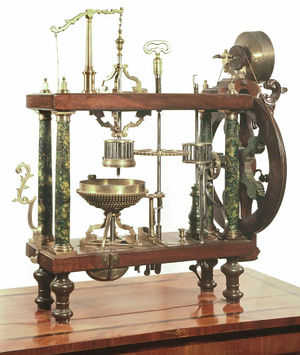

Ippolito Francini of Florence, who furnished lenses to Galileo, produced laps using a lathe with a pivoted boring bar that could cut an accurate portion of a hemisphere. The same machine was also used to polish lenses by substituting a buffer for the cutting tool. The cavity's radius of curvature was controlled by adjusting the length of the rod that held the cutting tool. The machine was sophisticated enough to incorporate a flywheel to smooth the hand-cranked rotation.

An important sidelight on the generation of spherical surfaces is that the curvature of the lens and the lap are "averaged" over both surfaces. Thus, the unavoidable irregularity at the exact center of the lap where the cutting tool ran out did not affect its usefulness.

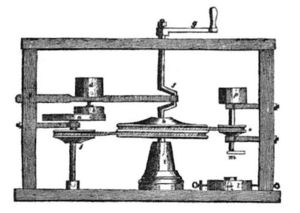

A contribution to lens making was the "baton," attributed to Christiaan Huygens, the 17th-century Dutch mathematician. The baton 's length was set roughly equal to the radius that had been lathe-turned into the lap. It could hold either a lens blank or a lap, and allowed a right circular cylinder of glass to be ground to the desired radius.

The baton was introduced to eliminate what we would regard as a second-order effect. In prior art, the lens had been manipulated on the lap by a handle glued with pitch to the upper surface of the lens. Since the handle was some distance above the worked surface, it was inevitable that the craftsman would apply a tipping moment to the lens blank while grinding. That created an imperfectly formed surface by applying more pressure, and hence more grinding, to the outer radius of the lens.

The baton kept the line of action of the force always normal to the spherical lens surface at the point of intersection with the lap. Jn use, the baton was manually given a back-and-forth motion across the lap while both turned. That produced a quasi-cycloidal motion between the lap and the lens blank. Grinding was accomplished by an assortment of abrasives of successively finer grades placed between the lens and the lap.

After grinding, the lens was polished, sometimes using the same lap that had been used to shape it. That required preparing the lap surface to remove roughness. In some cases, it was done by overlaying the surface of the lap with a specially prepared paper. In other cases, a method still used by amateurs to polish telescope mirrors was used. Pitch was poured on the lens surface and, when it hardened, was removed, creating a cool exactly matching the curvature of the lens. Pitch is firm enough when hardened to use as a polishing tool.

Procuring glass suitable for telescope lenses was a problem. Initially, the best glass was cut from pieces of the famous mirrors made on Murano, an island off Venice that is still famous for glass production. Since one surface of a lens would already be optically acceptable, production initially favored piano-convex lenses.

When it became possible to make generalizations about the performance of telescopes, it became obvious that the spherical aberration due to the shape of simple lenses was a factor that limited optical quality.

Famous Grinders

Johannes Kepler first recognized that a hyperbolic lens (if one could be made) would eliminate spherical aberration. That was a profound observation, which led to a major effort by workers whose list of names resembles a Who's Who of 17th-century science. Scientists, philosophers, and mathematicians, whose works are monumental to this day, but who were not above actually grinding glass, include Descartes, Fermat, Galileo, Hooke, Huygens, Kepler, Newton, Spinoza, Torricelli, and, curiously enough, the British architect Christopher Wren.

Another aberration was observed and explained by Isaac Newton in 1672, when he discovered that white light was, in fact, composed of colors that were refracted to varying degrees. That caused an image to be surrounded by a colored rainbow known as chromatic aberration. When Newton performed experiments to measure refractive index, he happened to choose materials with the same properties and jumped to the conclusion that all transparent material had the same index.

On that basis, he declared that an achromat was impossible. It is interesting that he ignored the evidence of his own eyes. The optics of the eye were well understood and it is obvious that the human eye is achromatic. Newton's misinformation stalled progress until 1759, when two men, C. Hall and J. Dolland, had the audacity to contradict him.

After Newton had given up the idea of an achromatic lens, he concentrated on his invention, the reflecting telescope, recognizing quite correctly that in a reflecting telescope, light was focused independent of wavelength. The vast majority of amateur-made telescopes today are reflectors.

The history of the lens is an inspiring example of the human mind's ability to create something out of essentially nothing.

Galileo brought about a revolution that continues to influence our lives after nearly 400 years. Armed only with a few pieces of shaped glass and the power of his intellect, he defeated 2,000 years of entrenched ignorance. He showed that the Earth is not the center of the universe and that the planets are governed by laws we can understand-not by a divine whim. Since Galileo and his telescope, the world has never been the same.