First-Hand:Starting Up Cetus, the First Biotechnology Company - 1973 to 1982

A response was written to the First Hand History referencing some of its claims

Chapter 1 - Cetus Beginning

Submitted by Roy D. Merrill, IEEE Senior Life Member

The genesis for Cetus,[1] the first biotechnology company, began with Pete Farley[2] who after mustering out of the Navy where he was the ship’s medical and diving doctor aboard a nuclear submarine, enrolled in the Stanford MBA program. Following graduation, he took a job with a venture capital company for an annual salary of $1. His sole intent was to learn that business first hand while making as many contacts among the successful Silicon Valley entrepreneurs and venture capitalists as possible.

Pete’s first attempt at building a company was based on developing a simple thermometer using the behavior of supersaturated liquid under small temperature changes. As a part time practicing emergency clinic doctor while in graduate school, he understood the marketing potential of such a device. To implement this idea, he sought out the top expert on the behavior of supersaturated liquids; Dr. Donald Glaser, chief of the Virus Laboratory and graduate professor at UC Berkeley. He had been awarded the Physics Nobel Prize for inventing the bubble chamber, a device used as a high energy atomic particle diagnostic tool based on the behavior of a supersaturated fluid when subjected to small changes in partial pressure. Specifically, under the right conditions, a stream of bubbles will form along the path of a high energy particle passing through the solution.

After studying the thermometer application, Dr. Glaser concluded it was not practical, and recommended it be dropped. Instead he, suggested an idea that originated with Calvin Ward, one of his brighter post-graduate students. Cal identified a microbiology analog to a well known electrical property: the electrical field strength measured from the edge of a straight charged wire varies linearly with perpendicular distance where as the field propagating from a point source charge varies exponentially with distance. A similar characteristic exists in microbiology petri dish assays where the distance to the edge of an inhibitor zone on the petri agar indicator lawn measured from a 6 mm pad strip saturated with antibiotic, varies linearly with drug concentration while on the other hand this distance measured from a 6 mm round pad varies exponentially with drug concentration. Because of this biological phenomena, a technician could indirectly measure drug concentration using a linear strip pad with an accuracy of at least one order of magnitude greater than that possible using a round pad. Cetus was formed and the first round of outside financing obtained in 1971 based on this new approach to implementing biomedical assays.

Drawing from Cal’s observations, they developed a simple device, called the “Cetus Fetus,” to measure indicator lawn inhibitory zone size, and organized a marketing business plan. Pete’s first task was to canvas a representative sampling of the hospital and clinical pathology laboratories in the SF Bay Area. To his astonishment, he discovered that the medical equipment & supplies manufactures were selling their round pad diagnostic supplies and measuring instruments at a loss (i.e., as a “lost leader”) as a marketing ploy to gain access to hospital and clinic staff where other more lucrative products might be marketed.

Despite this discouraging development, his backers urged Pete to go ahead with a third attempt at building a company. It was based on a modified version of Dr. Glaser’s ideas on a NASA Lunar project microbe screening system. To do so, Pete joined with four others to form a partnership and start up a biotechnology enterprise. The partners were Ron Cape with a doctorate in biology and substantial business experience in his family’s Canadian pharmaceutical company; Mosche Alafi, a venture capitalist with strong finance credentials who shared in starting up the North Face outdoor equipment business; Dr, Donald Glaser, the UC Berkeley graduate department professor in Viral Biology that had been awarded the 1960 Physics Nobel Prize for inventing the bubble chamber; and one of Don’s brighter post-graduate students, Calvin Ward with a doctorate in physics.

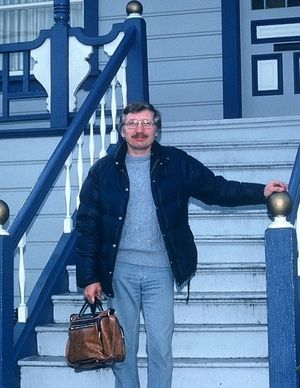

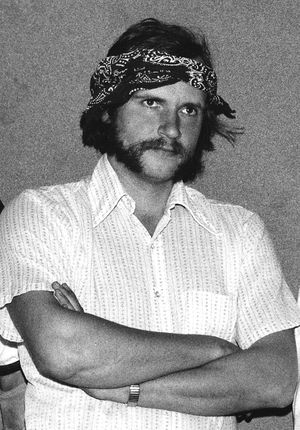

The following photo of Ron Cape and Pete Farley was taken from the Cetus prospectus:

Pete, Ron, Moshe, and Don each were given a full partnership share and Cal was given one half a partnership share in the company formed in 1971. Ron Cape was appointed president and Pete Farley vice president of the enterprise. Later in 1977, Ron moved up to board chairman, and Pete took over company presidency.

Early in the company’s history, Pete with his partners help, staffed the company’s Scientific Advisory Board with some of the brightest people around at the time: Dr. Joshua Lederbeg, President of Rockefeller University with the 1958 Biology Nobel Prize for discovering that bacteria could have sex and exchange genes, thereby establishing the foundation of modern genetics and biotechnology; Dr. Stanley Cohen who in 1973 was immortalized along with Dr. Herbert Boyer as the inventors of the DNA cloning technique, which allowed genes to be transplanted between different biological species; their discovery signaled the birth of genetic engineering; and Dr. Carl Djerassi, Professor of Chemistry at Stanford University, and later, President of Zoecon Corporation, who was inducted into the Hall of Fame in 1978 for his invention of the modern oral contraceptive commonly referred to as the “birth control pill”.

Shortly after they formed the partnership, Calvin Ward, while scuba diving off Sea Ranch with his Oakland sanitary worker buddies, was bitten by what he thought at the time to be a killer whale. Noting that Cal survived the ordeal, the partners took it as a good omen, and named their company Cetus, latin for toothed whale. As an aside, later Cal on a hunch, checked his wet suit for any evidence of his assailant and found a small shark’s tooth. Upon examining it, a marine biologist identified his predator as a great white shark, and not a killer whale after all. By that time however, the partners agreed to keep the Cetus name.

Chapter 2 - The Cetus Mass Screening System (CMSS) Development

With the original investor’s consent, and after the thermometer and assay device ideas proved impractical, the partners redirected there effort from instrumentation to implementing a pharmaceutical system based on a logical extension of a project Dr. Glaser and his Cal Berkeley university graduate students worked on regarding mass screening of microbes that possibly had returned from a NASA lunar probe. That effort was directed at developing automated methods of doing ordinary bench top microbiology on a massive scale. Several applications came to mind immediately, the most promising of which was pharmaceutical drug producing strain improvement. Don’s NASA system had been conceived to quickly determine whether any toxic microbes had been carried back to earth on returning lunar mission astronaut’s space suits; and to do so before releasing the astronauts from their quarantine trailer.

Instead of using large 12 x 15 inch agar plates to grow-up isolates into colonies for morphological studies as was done in the NASA system, Cetus microbiologists decided to use 12 x 15 arrays of small test tube-like wells in a plastic tray each to be inoculated with a single isolate; i.e., a viable mutant of the parent strain under investigation. Then after allowing the isolates to grow up in a nutrient solution, add an assay reagent to check for promising drug production properties. As part of this NASA system adaptation, the Cetus microbiologists used intense UV and/or chemical mutation agents to scramble the parent strain DNA gene’s with the objective of producing a few viable protege, from among the approximately 10 thousand viable isolates screened each week.

The mass screening process used a hundred or so of these trays molded into 12 x 15 arrays with ~5 milliliter wells; a parallel pipetting machine comprised of a 12 x 15 array of pipettes connected to a large manifold for inoculating isolates, transferring nutrients and loading ph-sensitive reagents into the wells; dozens of large New Brunswick shakers that stirred large assemblages of these trays to oxygenate the isolate microbes while they were growing up in the wells; and several large warm rooms operating at high temperature and humidity, for housing these shakers during the microbe incubation period.

A staff of microbiologists and technicians performed the parent strain mutation; colonized the results on petri dish agar; streaked-out the viable isolates; transferred them into a nutrient bath; loaded the result into the pipetting manifold; and injected measured quantities into each of the tray wells as needed to on-average inoculate each well with just one mutant; load/unload the shakers; incubate the trays of isolates; transfer an assaying reagent into the wells; search for any ph change with unusual color changes; and transfer these potentially high producers from their tray wells into shake flasks. These potentially high producers then were scaled up first in shake flasks, then into bench-top fermentors, and finally, large pilot plant fermentation vats.

After solving varies problems with contamination, and equipment glitches, the Cetus Mass Screening System did result in significant production improvements ranging from 25 to 30%, for the parent strains of Gentamicin, Erythromycin, and Penicillin.

The Author’s Experience during the Cetus Mass Screening System Period

Introduction: Pete Farley and his wife, Loretta, lived next door to my family in Los Altos-Mt. View. After learning about my computer science and control theory graduate training at Stanford U. and work experience in electronics engineering and computer science at the Lockheed Palo Alto Research Laboratory, Pete offered me a job with a generous stock-option package. I joined some 20 other employees in starting up Cetus in 1973 as a microbiology strain improvement (pharmaceutical) biotechnology company. My first job was managing the computing facility supporting the Cetus Mass Screening System (CMSS).

Initially, my assignment was managing a computer center and developing software support for CMSS that included developing an isolate assay analysis program; an isolate production vs time database storage and retrieval system ; and an isolate production analysis program. I also assisted Engineering in interfacing a large agar plate laser scanner to the center's PDP-11 digital computer; and developing the scanned data preprocessing and analysis program to discern the inhibitor zone sizes of large arrays of assay tests on each plate. With that job nearing completion in 1975, I was asked to consider some of the instrumentation and control activities supporting CMSS.

Microprocessor-based Shaker Monitor Development Effort

At that time, a serious engineering problem developed that was costing the company considerable effort, time and resources; specifically, during typical CMSS runs, a dozen or so New Brunswick shakers were loaded with system trays and shake flasks to sustain the newly identified high production mutants among the some 10 thousand isolates handled weekly. Unfortunately, the shakers were not very reliable and often failed, sometimes at night, with the result that the microbes growing up in these tray wells and shake flasks died for lack of oxygen. The cost of each failure was estimated at $10,000.

To combat this problem, the Engineering Department, managed by Dave Hansen, an instrumentation physicist, developed a shaker speed monitor. It consisted of a flywheel rotation optical sensor connected to electronic detection circuitry and power supply that was packaged together and mounted on each shaker frame. It was designed to sound audible and electronic alarms whenever a shaker’s speed dropped below a set level. Initially, these speed monitors performed satisfactorily.

Unfortunately, after several months operating in the 100 deg. F temperature, 95% relative humidity warm room environment, the monitors started failing. Their failure rate soon exceeded that of the shakers. The engineering electronics staff, lead by the principle electronic technician worked frantically to find a satisfactory solution. As this drama played out, Al Nies, an old friend and senior electronic technician in Engineering, dropped by my office one day to describe this shaker predicament. He had studied the problem, and came up with a solution to their problem. He discussed his ideas with the engineering staff, but they continuously postponed considering his suggestions.

Al and I had become good friends as we shared a love for scuba and abalone diving. I knew Al to be level-headed, extremely bright, and a very good electronic technologist. Consequently, after studying the problem, I didn’t hesitate in joining Al to convince upper management that we could solve this shaker speed monitoring problem ourselves. Management was receptive to the plan for two reasons: I had a proven track record managing the Computer Facility and developing the CMSS data management software applications; and second, the Engineering Department had been unsuccessful for several months in correcting the monitor’s high failure rate.

Al’s idea was to leave the shaker rotating speed pickup on the flywheel frame, but move the electronic detection circuitry and associated power supply outside the warm room. My contribution was to propose using a brand new technology, embedded microprocessors, to facilitate Al’s design implementation.

Before leaving Lockheed Palo Alto Research Laboratory for the Cetus job, I had studied the microprocessor technology, and knew about its first practical application, the hand-held HP pocket calculator. I had learned that Pro Log, a Monterey-based business, had started marketing a family of printed circuit boards built-up around the Intel 4040 microprocessor. Their product line included a family of matching elements: a card rack with integrated power supply; digital input and output cards; random access read and write memory (RAM) cards, and programmable read only memory (PROM) cards. Their product line also included a PROM Burner; specifically, a device that loaded (burned) the PROM chip with microprocessor instruction code the operator entered via a hexadecimal keyboard with matching laser diode (LED) display; and a System Analyzer by which the operator could stop the processor clock at a specific address in a program code sequence execution, and observe the processor state via a hexadecimal LED display.

Cetus upper management liked our ideas and gave the go-ahead to develop a demonstration prototype. The Engineering manager was surprised and upset that they would not let him continue their search for a solution. Countering manager’s prediction that Al and my design would not work any better, Upper Management pointed out that the Engineering group had been trying to correct this problem for several months without success. Clearly to them, it was time to try another approach.

Within five weeks, we had developed a design, ordered the necessary electronic and microcomputer parts, and taken the Pro Log training classes on using the microprocessor in engineering applications. Five weeks after that, we had the prototype built, and the software control program coded & debugged. We scaled it to handle a dozen shakers, and interfaced it with Cetus’ Security Company. With that link-up, detected shaker speed failures were quickly passed to the on-call technician.

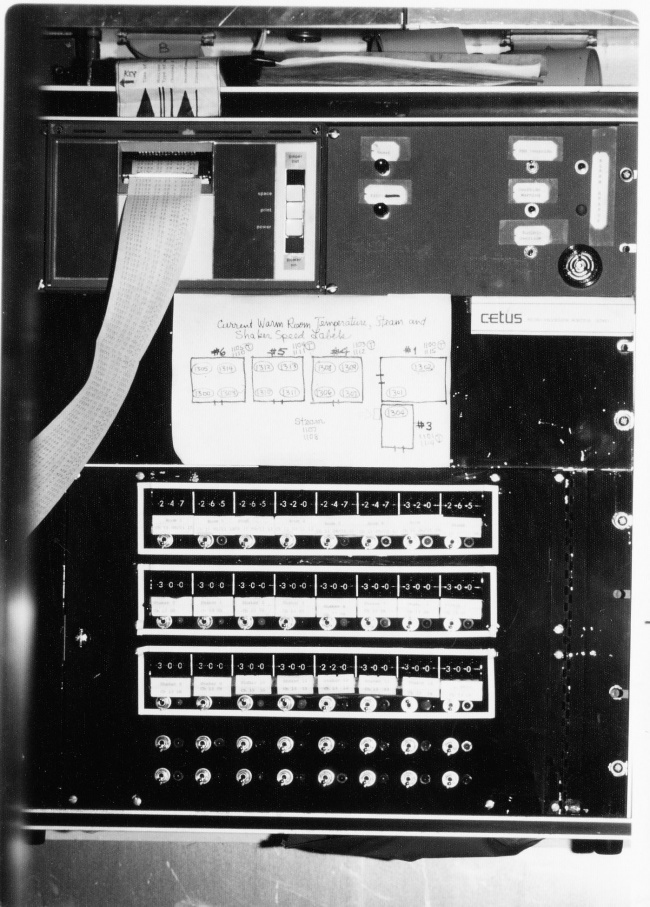

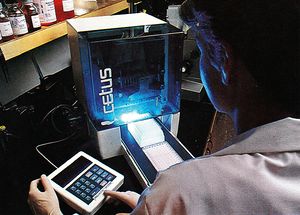

Cetus management, and the Engineering and microbiology staff watched our progress very closely for several weeks. During that time, two shakers did fail, but the microcomputer based monitor signaled the Security Co. which quickly alerted the maintenance technician. He in turn, had time to move the trays and flasks to another shaker before any of the affected microbes were asphyxiated. This new monitor had performed as promised. Upper management was satisfied; and gave the go-ahead to expand the capacity of the monitoring system to the shakers in the remaining warm rooms. The monitor implementation, pictured below, was replicated for each shaker warm room; all of these operated for over seven years after that without failure!

Shown above along with a strip chart recorder, comprising three array’s of eight monitoring enable-switches each with an associated 3-digit LED shaker rpm display, all encircled with white stripped tape is 18” by 15”.

Not too long after Al and I had successfully completed the microprocessor-based shaker monitor implementation, we were asked to solve other problems the Engineering Department had failed to implement properly.

With these added responsibilities, Doug asked me to consider relinquishing the Computer Facility assignment and taking over the Instrumentation and Control Group including the associated development and I&C maintenance responsibilities. I agreed since by that time I had hired and trained a computer software programmer to support the Computer Facility and the associated Microbiological Data Management Software. Further, the manager of the Cetus accountants, had been harassing me during the final phase of developing the isolate production sorting and analysis software. Why he did this I never fully understood.

Parallel Pipetting Filling Machine Embedded Microprocessor Controller Development Effort

A few weeks after the shaker monitor success became generally known among the Cetus microbiology staff, one of them, Bob Bruener, ask for help. It seems that over the course of the past year, the CMSS crew had been suffering a malfunctioning parallel pipette transfer machine. The main complaint was that sometimes when the operator signaled it to lift or lower the pipette array, it would dump the full contents of its manifold of inoculate or nutrient or ph indicator liquid. It appeared to be due to vibration induced into the manifold-parallel pipette assembly as the lifting mechanism began movement. This disturbance in turn caused a loss of surface tension within one or more of the pipettes which caused air bubbles to stream from the pipette tip into the manifold. This chain of events in turn caused the vacuum pressure to drop precipitously and dump the entire contents of the manifold basin out through the pipettes. After studying how and when these dumping failures occurred, it became apparent that the abrupt starting and stopping of the lifting mechanism was the primary cause.

The solution was to find a way to slowly start and stop the lifting mechanism. To do this, I proposed replacing the big awkward on-off relay controlled stepper motor power drivers with compact stepper motor power drivers whose stepping rate could be controlled directly by a microprocessor digital output stream of electronic pulses. Dave Hansen, the engineering manager, stated flatly that microprocessor wouldn’t be able to accomplish the necessary smooth movement transitions with our design. We proceeded without his blessing.

Al connected one of the microprocessor digital output channels to supply this electronic pulse stream to the stepper power driver. I wrote the embedded microprocessor control code so that it generated an output pulse stream beginning from a stop condition and smoothly ramping up the pulse rate to cruise stepping rate, then as the lift mechanism approached the desired stopping point, smoothly ramping down the stepper rate to a stop. On repeated tests of this new implementation, and subsequent extensive field operations, the filler machine never dumped its loaded manifold again. The Engineering Group Manager's judgement had been proven wrong again.

Because the microprocessor logic instructions were executed with the precise timing of its crystal controlled oscillator, I was able to calculate exactly how many microseconds it took to execute each of the instructions in the control program. Hence the time interval between consecutive output pulses could be easily altered by varying the number of “no op” “do loop” instructions between pulses. Moreover, there was enough time between even the shortest interval between consecutive output pulses to intersperse a read input signal branch-on-compare code string without altering the necessary ramp-up, cruise, or ramp-down output pulse rates. Using this coding method, the limit-switch, emergency stop-switch, and bench mark position flag-switch states were routinely checked as the lift mechanism stepper motor pulse generating commands were being executed. If either the limit switch or emergency stop switch state were asserted, the control code was programmed to bring the lift mechanism movement smoothly to a stop, and output an appropriate alarm signal. When the bench mark position flag was encountered by the optical pickup on the lift, the internal distance measuring counter was updated with the known step count for the associated bench mark position. It was possible, if the current count was different than the position flag count, an alarm code was displayed on the control console.

Also at about that time, the manager of Engineering and the other two fellow instrumentation physicists were in the process of leaving Cetus. Sometime later, the Accountant manager also left Cetus and went to work for a sheet metal fabrication business in San Leandro.

While developing the filling machine embedded microprocessor controller, I began experiencing criticism from the Cetus’ chief of microbiological R&D. He demanded that I stop this development, and redirect the effort to his design, a general purpose microcomputer machine that he thought could be easily adapted to handle the tray filling task as well as several other outstanding instrumentation and control problems. I resisted his badgering, and asked Doug Miller, Cetus’ Operations Manager, whether to follow the R&D chief or continue on my own course. Doug was adamant, do not listen to the Microbiological R&D Chief, and sit tight as there were plans afoot to handle this situation. Sometime later we learn that the Microbiology R&D Chief had left and enrolled in studies to become a patent lawyer.

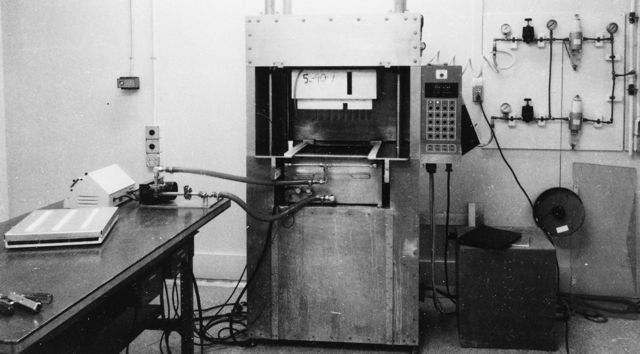

Bob Bruner, and his associate microbiologists, Jeff Flatguard and Jon Raymond, routinely checked our filler machine development progress. As they learned more about the capabilities of the embedded microprocessor control code, they suggested improvements to the operator interface and added functionality in the control modes. With their help, I designed the implementation so the operator, using a control console with a numeric keypad, two push-buttons, and an alphanumeric display, could set the volume of liquid to be sucked into the manifold; and the incremental volumes that were to be injected into the tray wells. The operator was provided with a set of control buttons with which he could initiate the pipet liquid injection pump, manifold-fill pump and pipette array lift mechanism moves. After this new filling machine & controller system shown below was completed and checked out; the pipette manifolds never dumped again!

Filler Machine with Controller

Shown above is the pipette manifold centered at the top of the opening in the filler machine housing, the control console just to its right with pressure regulators in an array on the wall behind the filler machine, and on the left is shown a 12x15 well tray with cover, and the pipetting liquid reservoir water bath temperature analog control.

New Applications for our Embedded Microprocessor Controls

As the parallel pipette filling machine effort was nearing completion, Our Instrumentation & Control (I&C) group was asked to develop microprocessor-based temperature and relative humidity controllers for four large warm rooms, one incubator room, and a large water bath system under construction.

This required that I&C interface analog-to-digital, and digital to analog converters with the microprocessor controller configuration where the ADC input channels were conditioned to interface with resistive temperature device (RTD) inputs; and the DAC outputs were conditioned to drive strip chart recorder channels. We used a “dual-slope” ADC on RTD and relative humidity sensor inputs to achieve the necessary high signal-to-noise conversions needed to obtain +/_0.1 degree F temperature control, and +/_ 5 percent relative humidity control, respectively.} In order to control room and water bath ambient conditions with this accuracy, it was necessary to design the controller to supply heater input for cold load conditions and refrigerant cooling for hot load conditions, respectively.

Chapter 3 - Cetus Retooled for the Genetic Engineering Revolution

In 1973, Stan Cohen & Herbert Boyer[3] created the first transgenic organism, a technique of DNA cloning, which allowed genes to be transplanted between different biological species; their discovery signaled the birth of genetic engineering. In Cetus’ case for example, the drug producing gene in the parent strain once identified could easily be replicated on the same DNA using this genetic engineering method to achieve higher drug production.

Sometime later, Cetus management reluctantly abandoned the CMSS, and redirected the personnel and infrastructure to capitalize on this new method of replicating the drug producing genes in the parent DNA using genetic engineering processes. This method showed astonishing promise over the mass screening method. Developing processes for producing Beta Interferon and Interlukin-2 were two significant results of this work.

It was soon clear to the planners that the full I&C crew would not be needed until Cetus had retooled for this new technology. Doug Miller, Operations Manager, ask that I lay off a number of I&C technicians; and gave Al, my senior electronic technologist, and myself the option of staying on with a skeleton crew, biding our time for 6 months or so until the role of I&C could be re-established. Coincidently, AL and I had been considering forming a consulting business of our own outside of Cetus. This situation was made to order for us, so we accepted immediately.

Chapter 4 - Our Consulting Business outside of Cetus

Hardly had Al Nies & I enrolled in an IEEE correspondence course on managing a consulting business, when a scuba diving friend of ours, Dave Atkins, asked if we might consider a problem that had just developed with his employer, a mail order electronic data processing company, Accounting Automated (AA) in Portland, Oregon.

Just a little earlier, the U.S. Postal Department had been spun off as a separate government entity. A serious consequence of this action was their postal delivery time doubled. Instead of AA’s CPA customers in Texas, Arizona, California, Oregon and Washington being able to have their budgetary data delivered via the mail to AA in Portland within 3 days, it was taking 5, sometimes, 6 days. Moreover, the same delays were being experience with the delivery of the EDP reports back to these customers.

Dave asked Al & I to consider developing a method of transmitting this data between AA and their customers over telephone lines. After studying the problem throughly, we assured Dave it could be done with a microprocessor-based store-and-forward terminal at the customer’s end linked via telephone data modems with the Honeywell computer at the AA Portland office.

Al &I formed our own company entitled M&N Associates. We were awarded a development contract by AA, and within four months, using this new microprocessor-based technology we had completed two prototypes. Al had decided to resign from Cetus so was able to put in full time on our contract. I, on the other hand, continued at Cetus putting in my 8-hr. days as usual, but spending a couple of hours before Cetus work every day, all holidays, and Saturday and half of Sunday each week on M&N’s business.

This effort took place in almost the same time frame as Jobs and Wozniak were developing the first Apple personal computer (PC) and a similar group at IBM together with Bill Gate’s at Microsoft were developing the IBM-compatible PC platform, but we didn’t realize it until almost a year later. The M&N machine had nearly all the same functional subsystems contained in Apple and IBM-compatible PCs including terminal and keyboard operator interface with spreadsheet application including audit and edit features, message editor, report generator, floppy disk software driver, telephone modem software driver, printer software driver, etc.

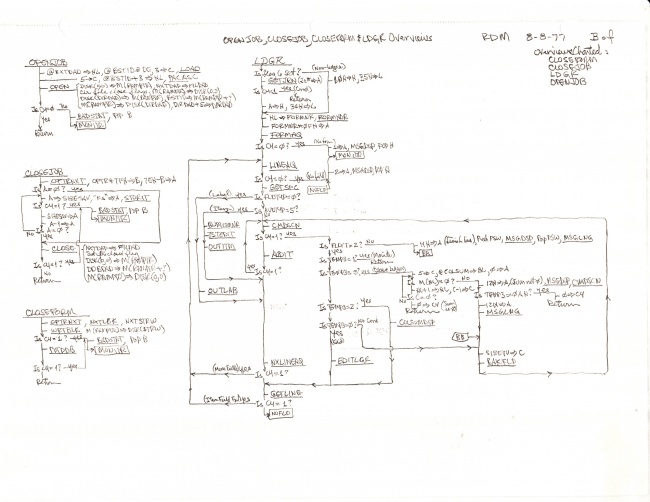

The following is the first page of the logic flow diagram documenting the top-level software for the M&N Store and Forward Computer application.

After we demonstrated this prototype, AA extended the M&N contract to build 10 engineering units. We accomplished that contract over the next 6 months. Field tests on these units by selected AA customers established the user community acceptance. From those results, AA was ready to contract for 200 units within that next 6 months. Unfortunately, because M&N did not have the necessary operating capital nor manufacturing infrastructure, we were not able to compete successfully for the production contract that followed. Al & I were obviously very unfamiliar with the fact that Silicon Valley was just teeming with venture capitalists, nor had we developed a business plan nor found an MBA willing to ferret out these potential sources. We just missed a golden opportunity; it was not in the cards for us to obtain the capital necessary to satisfy AA’s contract requirements.

Chapter 5 - Rebuilding the Cetus Instrumentation & Control (I&C) Group

I&C Group began in 1977 to work on several machines for the new Cetus genetic engineering enterprise. In rebuilding I&C, I first hired Al Johnson, as the I&C electronic technician Lead; next, Jim Zeitlin, an electronic circuit designer and software engineer; and finally, Joseph Widunas, an electronics draftsman. Each of these employees turned out to be exceptional in their respective fields. Jim, for example, had worked on the Altair 8800 S100 microcomputer operating system software, until Altair went under. I immediately gave Jim the assignment to develop a real-time operating system for the Prolog Intel 8080 microprocessor. The result was a very simple system that had just the right functionality! Even though Jim hadn’t finished his BS(EE), he turned out to be an accomplished digital circuit designer, and software engineer as well.

Al Johnson came directly from a bio-instrumentation firm with the skills and knowledge to setup the necessary equipment, and hire the electronic technicians to accomplish our up coming biomedical device assignments.

Joseph Widunas, was a skilled draftsman and mechanical designer; just the capabilities we needed for this work. It was not surprising that Joe’s capabilities came naturally as his uncle was a very famous west coast artist and sculptor.

Initially, my I&C Gr. consisted of two R&D electronic technicians and three maintenance techs; all skilled competent workers. Later it was to grow to 15 personnel as shown.

Developing the Serial Dilution Machine

I learned somewhat by chance that Kari Salomaa, one of Cetus’ mechanical engineers, had been charged with developing a machine that could perform serial dilutions over 12 rows in an 8 x 12 well micro-titer tray. He worked on the problem for several months without successfully perfecting the machine. His design used many cams, eccentrics, relays, detents, ratchets, and microswitches. These mechanisms were difficult to adjust, and regularly lost alignment and positional accuracy.

I discussed these design problems with Kari, but he resisted help. In frustration, I talked with Doug Miller, Cetus’ Operations Manager; Steve Golden, Cetus’ Microbiology Production Manager; and Pete Peterson, Engineering Manager. With my successful embedded microprocessor implementation of the shaker table monitor and filler machine systems, both Doug & Steve trusted my engineering methodology and design judgement. Doug talked with Kari about his slow progress, and asked him to consider working with me. He reluctantly agreed.

I immediately laid out a design incorporating stepping motors, optical sensors, solenoid actuators, and microprocessor controls integrated with Kari’s mechanical design. Pete Peterson, the Engineering Manager, stated emphatically that my design would be impractical. He envisioned my implementation as one with an unwieldy array of displays and control switches.

Within 2 month, the I&C group had, with Kari and his mech-tech. completed an operational prototype that had only one 5-digit LED display, and two buttons for incrementing and decrementing the nominal pipette volumes, and numbers of mixing cycles. Peterson, failed to acknowledge our success! Ron Cape, the Cetus CEO, did acknowledge Engineering’s effort with a backhanded compliment: “it appears to be doing an excellent job, but what do I know!” Ron had illustrated once again that he was a ‘prince‘ of a fellow.

The microbiologists, Bob Bruener, Jeff Flatguard, Jon Raymond, and Saul Neidleman, were so impressed with the resulting prototype that they recommended it be upgraded, and four operational versions built. The resulting machines proved reliable and easily controlled, so much so in fact that management decided to have it patented. Later they hired an outside product design specialist to upgrade its appearance, while retaining all its functionality. Cetus marketed the result as the Pro/Pette, and sold over 2 thousand units; one to nearly every blood bank in the country.

Kari, an MIT graduate, is a talented designer. He is the off spring of Finnish parents who immigrated to the US after WWII; Kari closely identified with the Finnish culture, and told many stories of his mother’s heroic exploits as a member of the Finnish underground resistance movement against the Russians.

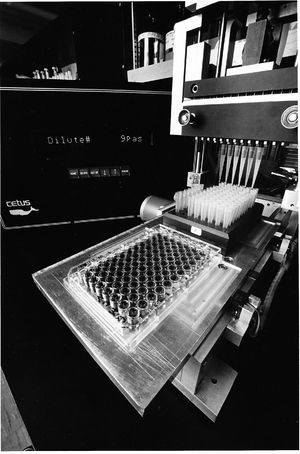

The serial dilution machine shown above has a horizontal movable table with an 8x12 well microtiter tray in the foreground, and an 8 micro-syringe array mounted on a vertically movable yoke having just ejected the contaminated pipette tips, and picked up a row of sterile tips from the 8x12 sterile tip array on the back of the table.

The serial dilution machine was patented under the title, “Liquid Sample Handling System.” The patent abstract follows: An automatic liquid transfer system includes a horizontally translatable table and a vertically translatable set of pipettes. The table accommodates a titer tray having a multiplicity of receptacles to be filled or holding liquid samples to be diluted, and a rack housing eight rows of disposable tips. During each cycle of a serial dilution process a fresh sterile set of tips are picked up by moving the bare pipettes over the sterile tip array and pressing the pipettes firmly down on the next row of sterile tips in the array, then the pipettes transfer liquid in a sterile manner from a sample or diluent source to a row of wells in the micro-titer tray, or from a row to a successive row of wells where it is mixed with diluent. Thereafter, the tips are discharged back into a rack for used tips thus maintaining sterile conditions during the process. A sensor is provided on the machine to detect whether all used tips in each set are discharged and another set successfully picked up.”

Development of a Fully Automated Bench-top Fermentation Control System

Sixteen operational versions of the system shown above were developed and produced by my I&C Group for Dr. Bez Koshrovi, the Cetus Biological Production Process Manager. A seventeenth copy was produced with my machine language control code converted to C-language code by Jim Zietlan. This machine was interfaced with a 300 liter vat and used to grow-up seed inoculant for pilot plant fermentation runs.

The hardware and software of this system were patented in mine and Kari’s name as principle inventors, and later described in an international peer reviewed journal article which I co-authored with Keith Bauer, a Cetus microbiologist. Specifically, Roy D. Merrill & Keith Bauer, “An Integrated Microprocessor-based Fermenter Control System,” Biotechnology and Bioengineering, Vol. XXVIII, Pp. 494-503 (1986) In searching the literature for relevant fermenter control related publications, it became clear that this machine was the first to use one imbedded microprocessor to control all variables, the operator interface, the output displays, and 6-channel strip-chart recorder as a completely automated stand-alone fermentation system.

The Fermentation Control System patent abstract follows: “A unitary control system controls a plurality of individual digital control systems for fermenter units operating independently of each other in response to a multiplicity of measured variables representing the reaction rates and end products of each fermenter unit. The energy input quantities, both chemical and physical, to each unit are controlled independently either locally or from a master control unit to achieve optimum fermentation conditions. Each of the plurality of fermentation systems, running under widely varying reaction conditions, is operated to produce any selected micro-organism under substantially differing, or substantially identical process reaction conditions. The individual fermenter control system includes an executive program using a high speed microprocessor bus for operating without system upset is provided to both the local, microprocessor computer and the central, minicomputer controller. The fermentation control system was particularly useful for research and development, for example, research involving recombinant micro-organisms to improve and optimize commercial production of such micro-organic species on a batch basis.”

Chapter 6 - Cetus Could Have Been Great

What if in the early 1980’s, Cetus had decided to keep the Engineering Instrumentation & Control Group, and later in the 80’s, the management staff had recognized much earlier the importance of Kary Mullis’ PCR discovery, and at the same time stepped down to let professionals run the company? (I believe there was a desperate need for better biological R&D management; and as so often occurs in new companies, the original entrepreneurs, particularly Ron Cape and Pete Farley, stayed too long! Had they relinquished company management to professional biotechnology administrators much earlier, it seems highly likely Cetus would have survived for longer than 20 years. As it turned out, Cetus was acquired by Chiron in the 1992; and Chiron, in turn, was acquired by Novartis International AG in 2006. The original Cetus R&D facility contained in the renovated old Shell Research buildings on Norton & 54 St. in Emeryville remains the Novartis complex in California.)

Prior to Cetus management deciding to reduce the size and scope of Engineering I&C activities in the early ’80’s, I had already contacted two companies about commercializing the serial dilution machine. If that course of action had been taken, the Pro/Pette could have been brought to market faster and at considerably lower cost.

Moreover, I&C would have been primed to address a second challenge of that time: an automated means of sequencing DNA. A new laboratory sequencing protocol method had just been published in the Biotechnology literature that would have made this implementation feasible.

More importantly, I&C would have been primed to commercialize the PCR (polymerase chain reaction) method[4] discovered in 1983 by Dr. Kary Mullis, a Cetus employee. Later, in the 1980’s, Dr. David H. Gelfand, a senior Cetus microbiologist, led a team that discovered the Yellowstone boiling mud pot bacterium, Thermus aquaticus, that thrived at 100C and produced the key enzyme,Taq Polymerase, needed to denature DNA at 90C in repeated cycles of the PCR process.[5] I&C would have been ready to tackle the reagent pipetting and 30C-90C-30C temperature cycling implementation necessary to commercialize viable PCR machines. Cetus received a PCR patent in 1991.

Rather than exploiting the PCR capabilities, Cetus sold their PCR process, arguably the most important discovery in biotechnology of the 20th century, to Hoffman-La Roche for $200 million in the early 1990’s.(Later, it was rumored, Dr. Peter J. Farley stated the sale amount was really closer to $1 billion.) Hoffman-La Roche has made 10’s of billions of dollars exploiting the PCR method. Shortly after Cetus sold the PCR process in 1991, the company was acquired by Chiron. Ironically, only 15 years early, Cetus had rented laboratory space in the newly acquired Old Shell Research Building in Emeryville, CA to a new startup, Chiron. Later in 2006, Novartis International AG acquired Chiron.

Probably, the saddest irony of it all was that at Cetus inception, Pete Farley stated his goal was to develop a biotechnology instrumentation company that would rival the commercial success of IBM. Had Cetus commercialized the PCR process, this dream undoubtedly would have been realized.

Chapter 7 - The Whimsical Side of Cetus

The Case of the Great Garbage Dumpster Fright: John, the early lead electronic technician, was the champion practical joker at Cetus. The first antic I had heard about involved John and a couple of his friends who after work, clearly had far to much time on their hands. While routinely consuming a 6-pack of Bud, they conceived many pranks. The most notorious of those was the great dumpster escapade!

It seems that in their spare time after work, they had been experimenting with coupling surgical tubing to an acetylene tank gas outlet valve and directing the other end of the tubing beneath an overturned 1 lb. coffee can, or 2 gal. bucket. This led to many escapades that produced almost uncontrollable mirth. On disconnecting the tube from the acetylene tank valve, and touching a lit match to the tube’s open end, flame would race down its length to the gas collected under the can or bucket, where it sparked an explosion that would propel the container to the ceiling of the Engineering High Bay with a great bang! This always caused peels of uproar-us laughter from John and his buddies.

With that success, John’s fertile mind next struck on the idea of filling a garbage bag with the gas. Then he had to decide where and in what container to place the bag before torching its’ contents? Well! the Cetus parking lot off Fourth street between Engineering and the Steam Works (a gay bath house) contained a large dumpster bin with dual lids. This seemed like just the perfect location for their next prank. The dumpster was located behind the parking lot lath woven cyclone fence almost completely hidden from the street. They ran the surgical tubing from the acetylene tank in the High Bay up the stairs, through an office window facing the parking lot, then down to the dumpster. The end of the tube was then tied off inside the garbage bag. The bag was filled with gas, the dumpster lids closed over the bag, and as before, John and company disconnected the tubing from the acetylene valve, and lit the gas in its open end. There was a momentary period of complete silence; the perpetrators held their breath looking at one another thinking their experiment wasn’t going to work, before a tremendous explosion rocked the dumpster and reverberated between the buildings and out into the street. The dumpster was deformed outward like a gigantic ball, and both dumpster lids were propelled up above the buildings, then down, one into the parking lot with a loud clang, and the other onto the roof of the Steam Works with a resounding thud. Witnesses standing outside the Engineering building saw the front door of the Steam Works fly open and more than a dozen men in various stage of undress came bursting out into the street thinking that someone had just bombed the place. Within 10 minutes the Berkeley police were alerted. Thinking the reported explosion could well be the result of a bomb set off by the Underground Weatherman Terrorist, they sent a patrol car cruising back and forth along 4th St. in the vicinity of Engineering looking for the cause of the explosion.

Fortunately, by that time the smoke had cleared, the nude steam room customers had returned to their activities inside, and the damaged dumpster and debris in the parking lot remained safely hidden behind the lathed cyclone fence and on the Steam Work building roof. John and his conspirators were lucky also in working for Doug Miller, a very tolerant Operations Manager.

It was not until 6 years later during the going-away party for John, that a gift was presented to him by his co-workers. At the urging of Pete Farley along with others there, John unwrapped the gift revealing a miniature replica of the infamous dumpster with bloated sides and bent lids. To those of us who knew of the dumpster escapade, it clearly represented the result of that fateful episode many years before. Pete was the first to ask John the significance of this replica. John then had to come clean and sheepishly confessed the incident to the speechless consternation of both Pete and other of the management staff.

The Case of the Japanese Sake Plant Advertising Fizzle: This prank came a little after the Carnation Milk Company sold their building across from Engineering on 4th street to a Japanese Sake Brewery. Upon completing several successful sake brewing cycles, the Japanese management opened a tasting room. To commemorate the occasion, they tethered a great helium filled dirigible-like ballon atop the brewery. With spot lights trained on the scene, their advertisements on the ballon sides could be seen for miles along the East shore freeway. Looking out the second floor windows of the Engineering build, one could see across the street, over the roof of the Sake Factory, and into the waters of the Berkeley marina channel just on the other side. One could also clearly view the ballon.

Well, as one might imagine, it was only a few days and just as many Bud 6-packs before John & his buddies came up with the perfect prank. They quickly cobbled together a large crossbow which with bicycle inner-tubes providing the resilience, could propel a 3-foot long arrow with sharpened point some 150 feet across the street to the vicinity of the sake advertising ballon. When the opportunity presented itself an evening or so later, they tested the device on a local high school ball field. With a few minor adjustments, the crossbow was declared operational.

They waited then for a busy Saturday evening with a large sake tasting crowd present. Large flood lights were again trained on the ballon advertisement flying brilliantly over the Brewer. John and crew quickly moved the cross bow into an engineering office with a window facing the Brewery. After posting sentries to make sure the coast was clear both on 4th St. and the marina channel behind the Brewery, they strung the bow, stretched the bicycle inner tube string tout and let the arrow go.

The arrow disappeared into the night in the direction of the ballon, but no one could be certain it had struck the ballon. They waited and waited for any sign that their dirty deed had been successful.

Thinking finally that the arrow had not accomplished its intended purpose, the perpetrators began disassembling the crossbow and moving away from the window, then looking back one last time, a member of the group thought for a moment he perceived that the ballon had sagged just a little. They waited a few minutes more and sure enough within a short time it was clear the large ballon had been punctured. Its drooping appearance grew worse and finally caught the eye of one in the crowd below. With this taster’s loud out cry, the sake tasting queue beneath the ballon began screaming and wildly running away. It took some time before finally the ballon, with a funny blubbering sound, sank to the brewery roof, draping itself over the eve then sliding down almost to the sidewalk. Again, the Berkeley Police were called upon to investigate this incident. They soon arrived and proceeded to patrol up and down 4th street looking without success for any clue as to the cause of this outrages event. To this day, no one either on the Berkeley Police Force nor in the Sake Brewery management staff have been able to prove from where the 3 foot long arrow had been launched, nor how it could have successfully pierced the thick inflatable ballon skin and deflated it so completely.

The Case of Another Character at Cetus, the Construction Manager, and Perpetrator of the Roof Garden Mystery: Memories of Joe Proctor (an alias since his actual name has long been forgotten), the Cetus Construction Manager, I had worked with in the mid-70’s, prompted this story. In conversations over a beer one evening after work, I learned that Joe was a WWII veteran, moreover, he had been a P40 & Corsair pilot in Maj. Greg. Boynton's Black Sheep Squadron. He related many harrowing experiences flying with Boynton and his pilots in their Corsairs against the Japanese air force over the Solomon Islands.

Joe owned a twin engine beach craft he flew between his ranch in Northern California and the Alameda Airport. He had a construction job in progress there, as he also had with his Urban Renewal crew in the East Bay. Doug Miller, our Operations Manager, knew of his contractors businesses outside Cetus, but was so impressed with Joe’s effectiveness in remodeling old ware houses into biological warm room facilities, he chose to overlook this and some other of his questionable activities. One of these was the considerable savings he realized in the wholesale discounts of large bulk orders obtained by combining his with those for the Cetus remodeling jobs. Another, and one that Doug never knew about, has been entitled “the Roof Garden Mystery/”

Joe was a blustery man and demanded a lot from his employees, but on the other hand, he took care of them. Especially, the down-and-out fellows that he had hired off the streets of Berkeley’s Telegraph Avenue. For example, he always had a big pot of stew brewing when his crew arrived on the job in the morning, and he often took them to Brennon’s Club for a beer in the evenings after work. Once these entry level fellows had a taste of Joe’s hospitality, he was their friend for life, and most often became steady hard working employees.

Which brings to mind the following incident. I was in the midst of coding real-time application software for the bench-top fermenter controller. Jim Zietlan, our software engineer and system programmer, had just completed the operational version of a real-time operating system for the Intel 8080 microprocessor (possibly the very first) we were using at the time, and I was developing the application software to run in this operating system environment to control the fermenter temperature, ph level, agitation speed, dissolved oxygen concentration, and foam level variables using second-order negative feedback algorithms as well as service routines to handle the numeric and function key pad entry of variable operating set-points and alarm limits; the variables plotting scale and offset for driving the 6 channel strip-chart recorder; and driving the alphanumeric LED display.

I was having the time of my life doing something that had never been done before. For example, to achieve comparable functionality prior to this implementation, the microbiology process engineers had routinely used a separate analog controller for each of the operating variables, as well as a separate off-set and gain amplifier for each variable displayed and recorded; and on top of that, it was necessary for a biotech to be in attendance all through each often multi-day experiment. My implementation was capable of being linked to a central laboratory computer and alarm system, and could operate unattended. It controlled all of these variables using just one microprocessor (linked to two 4-bit discrete input/output registers, a 6-channel 12-bit analog-to-digital converter, a 2-channel 8-bit digital-to-analog converter, a 10-numeric and 6-function keyboard, and a 12-character LED display) which was a significant achievement. A process lab. microbiologist co-authored a paper describing this development in a peer reviewed international journal: Roy D. Merrill & Keith Bauer, “An Integrated Microprocessor-based Fermenter Control System,” Biotechnology and Bioengineering, Vol. XXVIII, Pp. 494-503,1986

At the time of this incident, I had finished and tested about half of what had to be done for a complete implementation. All tests assured me that the microprocessor could easily handle the complete application.

My work routine was to arrive in the office about 2 hours ahead of the engineering and technician staff, tune in Dr. Don Rose, a very funny disc jockey on KFRC-AM at the time, and listen to his rock & roll music and comedy while coding the control software. The music put me in a relaxed mood, so that I could concentrate exclusively on the task at hand. It was a euphoric experience, and one I looked forward to every morning. My office was on the second floor with a door opening into the hall with another door opposite my office that opened out onto the high bay roof. There one could view the building roof top stretching out about 20 feet to a short 3 foot high separating wall, and then on another 20 feet over the roof housing the engineering drafting room and technician lab space. Normally, in the summer time I left my door open for the fresh air. However, I noticed that regularly one of Joe Proctor’s go-fers would trudge up the stairs every morning carrying large heavy buckets.

He would proceed out the roof access door carefully closing it behind him, then move on to accomplish some mysterious task there before returning and shuffling back down stairs. This morning ritual continued for two weeks, or so until one day I could no longer contain my curiosity. After the young chap completed his daily task, and disappeared down stairs, I quietly opened the outside door and searched the roof for some sign of what the young lad had been up to. It only took a few seconds to spot a row of spindly green stems just peeking over the 3-foot high separating wall. On closer inspection, I discovered three dozen potted plants flourishing there in their solitary place. Obviously, the young man had been watering and feeding those plants during his daily visits.

Not recognizing their species, but thinking something strange was going on, I clipped a leafy branch off one plant, and pressed it between the pages of a reference book. The next weekend, with book in hand and during one of our many trips to the local nursery, while Ina, my wife, was shopping, I asked one of their horticulturist to help me identify the clipping. The nursery man studied the leaves briefly, then lead me into his potting shed for a closer inspection of similar plants displayed in his reference book. He then turned to me and said, “Well, it is just as I suspected. You have in your possession a marijuana plant. I’m not going to ask you where this clipping came from, as even possession at that time was probably an illegal act.”

In the course of the next week, the young water boy continued on his appointed rounds. On about the third day, and after noting the plants had grown another 3 or 4 inches above the separating wall, I asked Joe if we might have a word.

After a brief silence, Joe turned, as if he fully expected me to accuse him of one of his nefarious acts. Instead I simply said, “you know Joe, one of your helpers is tending a crop of marijuana on the roof, and my main concern is that the Operations Manager might accidentally happen upon the crop and most certainly go ballistic!” With a shocked look on his face, he nervously assured me that he would look into the matter right away.

I noticed on the next morning when normally the go-fer would have carried out his bucket delivery task, there was complete silence. Well, of course you guessed it, my next action was to check the space behind the separating wall. It was completely bare as if nothing had been there. The incident was never spoken of again.

Notes

- ↑ After reading Eric Vettel’s Book entitled: “Bio Tech: Counter Culture Origins of an Industry,” I was compelled to tell my own Cetus Story.

- ↑ Dr. Peter J. Farley, a pioneer in the field of biotechnology and a lifelong entrepreneur, passed away at his home in Redwood City, Ca., on Monday, June 7, 2010, at the age of 70. Dr. Farley spent 30 years as an innovator in the biotechnology industry, having co-founded Cetus Corporation, one of the first biotechnology ventures, in 1971. During the 15 years that he led the company, he directed the work of over 200 Ph.D.s in the disciplines of molecular biology, computer science, and drug development. One of these scientists, Dr. Kary Mullis, discovered the process of Polymerase Chain Reaction (PCR) for which he was awarded the Nobel Prize in Chemistry in 1993. Under Dr. Farley’s direction, Cetus completed the largest IPO at the time and discovered and developed several major drugs, including the MS treatment Betaseron and the renal cancer drug Proleukin.

Following his retirement from Cetus, Dr. Farley pursued an entrepreneurial career personally founding and funding start-ups spanning the fields of healthcare, E-commerce, electronics, and even a custom boat company. Throughout all of his endeavors, he remained passionate about curing world diseases and supporting cutting-edge research.

He received his M.D. degree in 1965 from St. Louis University. Following a period of surgical training, he served in the U.S. Navy during the Vietnam era as the medical and diving officer aboard a nuclear submarine. Following his discharge from the Navy, Dr. Farley graduated from the Stanford University Graduate School of Business in 1971, becoming the first physician in Stanford history to obtain an M.B.A. He later served as a biotechnology/pharmaceutical industry advisor to the Reagan Administration and testified before Congress regarding health care cost containment.

Dr. Farley was an avid fisherman, sports car enthusiast, gregarious storyteller and lifelong philanthropist. He was beloved for his bold intellect and generous spirit. He is survived by his mother Mary, sister Susan, former wife Loretto, four children (Kathleen, Brian, Shannon, Maureen), and his three grandchildren (Finn, Kai, Teagan), as well as by countless adoring friends, family members and colleagues. - ↑ Shorty after the genetic engineering discovery, Dr. Boyer joined with Dr. Robert Swanson to form Genentech Corp. in 1976

- ↑ The PCR process is extremely powerful, for example, with just a snippet of DNA, say that removed from under a finger nail, a hair strand, or blood smear in a violent murder scene, can be multiplied exponentially over a billion times in just 30 PCR replication cycles in less than 2 hours. With this process, for example, CSI units routinely use this process to determine the identity of individuals who produced the snippets.

- ↑ Journal of Biomedical Discovery and Collaboration, 2006, 1:7doi 10.1186/1747-5333-1-7 “The effects of business practices, licensing, and intellectual property on development and dissemination of the polymerase chain reaction: case study,” by Joe Fore Jr, Ilse R Wiechers and Robert Cook-Deegan Center for Genome Ethics, Law & Policy, Institute for Genome Sciences & Policy, Duke University, Box 90141, Durham, NC 27708, USA. Massachusetts General/McLean Hospital Adult Psychiatry Residency Program, 55 Fruit Street Wang 812, Boston, MA 02114, USA.