First-Hand:Seeing the Light on Ennylabegan

Submitted by John O’Donnell, IEEE Life Member 02/15/2019

“You do know we’re on an island”. It was February, 1970 and the island was Ennylabegan, 500 yards wide by a mile long spit of sand in the Kwajalein atoll of the Marshall Islands. We were in a U.S. Army 1950s era transient quarters billet and the man shaving a few sinks down from me noticed that I had the water running while shaving and pointed out to the newbie on the island that fresh water was limited and precious.

Ennylabegan (code named Carlos by the U.S. military) hosted a tracking and telemetry station, part of the then U.S, Army anti-ballistic missile test facility at Kwajalein. I was there as a freshly minted practicing engineer only eight months out of University of Pennsylvania’s Moore School of Electrical Engineering MSEE program, working for a Fort Washington, PA based electronics company, Monitor Systems, that provided PCM (pulse code modulation) telemetry receiving, synchronization, and decommutation equipment and systems to the aerospace activities of the government and government contractors.

My assignment on my hiring in June, 1969 was the redesign of a stored program PCM telemetry decommutator (also referred to in this paper as a decom or PCM decom), designated the model 1126A, Figure 1, to increase its data rate capability from 1.2 Mbps to 2 Mbps and update other features including data compression, paper tape program loading, computer interface, and 4K core memory used for decommutation and data compression program storage to meet the specifics of a contract with a Kwajalein range contractor, LTV Kentron. The decommutator would be the heart of a ground station upgrade in the tracking, telemetry, and control station on Ennylabegan.

In those days there was no practice of assigning a new hire to a subject matter expert to learn the ropes, at least in a small company like Monitor Systems. I was given a tutorial article from Aerospace magazine on PCM telemetry formats and ground station reception, synchronization, and processing of PCM streams, and a set of 48 sheets of D-size blue line logic drawings of the then current product to be redesigned and upgraded.

I also had to take a deep dive into the specifics of implementation: logic function cards, called Monilogic cards (Fig 2) plugged into 32-cardslot frames. The chassis, 27 inches tall, had eight of these card frames split between two swing out wings, one on either side, for a total capacity of 256 cards. Backplane wiring for card interconnections was Gardner Denver Termi-point. The company not only designed products using its Monilogic card line but also sold them to other companies as an implementation means for their own products.

Monilogic cards were slightly smaller than an index card, and implemented SSI (small scale integration) and MSI-based (medium scale integration) logic functions, for example cards of gates, inverters, buffers, flip flops, registers, counters, etc. They had convenient test point blocks on the top edge for probing signals with a scope probe. Logic functions were implemented by interconnections between Monilogic cards in a Termi-pointwired backplane. In many cases new cards had to be designed for higher level functions specific to the application such as binary and BCD adders with clocked input and output registers.

The heart of the redesign involved replacing an analog, sum of currents 33-bit frame sync pattern correlator with an all digital, pipelined correlator with programmable bit error tolerance, and designing a new instruction set for decommutating telemetry channels sampled at the frame rate, or a multiple of the frame rate, supercommutated, or submultiple of the frame rate, subcommutated, and in compliance with the standard for aerospace PCM telemetry formats, IRIG-106, published by the Inter Range Instrumentation Group.

Once the decommutator found the frame synchronization pattern, using a Search, Check, and Lock strategy, each mode with its own programmable error tolerance and number of pattern tests before advancing to the next state (Search to Check, Check to Lock or back to Search, and Lock to Lock or return to Search) a so-called distribution instruction was fetched from core memory for each PCM format time slot, the instruction detailing the number of bits in the time slot, the orientation, LSB or MSB first, and an ID tag passed along with the operand to the computer interface. The Distribution instruction could also direct the operand to the Data Compressor which performed operand filtering based on floating point and fixed point limits programmed for the format time slot so that data flow to the computer could be throttled by passing only when in limits or out of limits, or based on rate of change.

So in my first assignment out of Penn I got to design a special purpose stored program machine within the context of an existing design, programmable manually through front panel pushbutton switch indicators, paper tape reader, or computer interface. It had to have multiprogram capability, selectable through the computer interface or manually by front panel thumbwheel switch.

I got to know every schematic sheet by heart and could impress coworkers by telling them the sheet number that any particular function could be found on. Somehow I accomplished all of this from June to December in ’69 while preparing with my fiancée for our wedding in October of that year. Thinking back I don’t know how I did it but the 1126A PCM Decommutator had to be ready for system integration in December, 1969 so system testing could be completed before customer acceptance testing in late January.

Customer-witnessed testing revealed inevitable glitches, many of which were not recognized as such by the customer but were by us, so the sales people would have them out for an extended lunch while problems were fixed for the rest of the day’s acceptance testing. The customer signed off and the system was shipped to Kwajalein.

On Friday, January 30, 1970 Bob Williams, the project engineer, and I flew to Hawaii where we stayed over to Monday to fly a MATS (Military Air Transport Service) plane to Kwajalein with a stopover at Johnston Island (Fig 3) in the Johnston atoll, about 900 miles southwest of Honolulu. Little did we know that we were about to have a brush with tragic cold war history. All the passengers were escorted from the plane to a cinder block block house waiting room until the aircraft was ready to continue to Kwajalein.

In the 50s and 60s Johnston atoll was a U.S. nuclear weapons test site, and in 1962 and earlier, was polluted by plutonium fallout from launchpad failures and a failed high altitude explosion of a nuclear-tipped missile, with disastrous long term health consequences for the personnel on site. In 1970, and still today, Johnston Island was and is a storage location for nuclear test waste cleanup and later, chemical weapons disposal, including Agent Orange.

Approaching Kwajalein (Fig 4) for landing I remember thinking that the landing experience was the closest I would ever come to knowing what it felt like to land on an aircraft carrier. Kwaj, as it is called by its residents, is a J-shaped island with the aircraft landing strip in the curve of the J and extending from water to water. It’s a thrilling experience to watch the landing approach and realize there’s an ocean dunking at the end of the landing strip if the landing goes wrong.

Kwajalein is leased by the U.S. Government from the Marshailese thru 2066 and hosts the U.S. Army Ronald Reagan Ballistic Missile Defense Test Site. In 1970 it was home to the Kwajalein Missile Range and was involved in defensive missile research involving ICBMs launched from Vandenberg AFB before such research was halted by international treaty.

We lay over a couple days on Kwaj and one of my memories of that interlude was visiting the Yokwe Yuk club (Yokwe Yuk: Marshallese for “I Love you”), Fig 5. The other overriding memory of Kwaj is that of a small middle America town set down in the vastness of the central Pacific, home to contractor and military personnel families.

After a 1 or 2 day layover, I forget how long, we boarded an inter-island boat with native islanders to get to Ennylabegan, about a 45-minute boat ride north of Kwaj.

Docking at Ennylabegan presented the sight of a WWII concrete-constructed supply barge scuttled to provide a breakwater for a protected anchorage. Prominent on disembarking was a large weathered wooden sign, Fig 6, with a plan of the atoll and lagoon and the area that must be vacated by islanders during a test shot from Vandenberg.

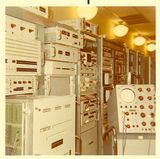

We were shown to our quarters, a couple cots in an open sleeping area in the transient quarters building, Fig 7. After settling in we went to the ground station building, Fig 8, a short walk away, to meet the station personnel and check out the system.

The station personnel, employees of LTV Kentron, the company that then had the contract with the U.S. Army to provide range services, had received our dual equipment rack system a week or two before our arrival and integrated it as a new front end to their existing telemetry processing system. In “system-speak” our data receiving and quick look front end subsystem had been positioned and connected to the station’s data processing back end subsystem.

Fig 9 shows our dual rack PCM Decommutation system front end comprising a bit synchronizer, model 317, a PCM simulator/modulator, model 820/821, the model 1126A PCM decommutator, and data display units including the models 725/726 digital displays, model 132 digital to analog converter units, and strip chart recorder unit. Fio 10 shows the PCM Decom system front end with model 1126A extended on slides and the station legacy equipment. Fig 11 shows project engineer, Bob Williams, working with the single channel digital display units, models 725 and 726. Fig 12 shows station personnel: lead operator, John Barsic, technician, Jack, “the kid”, and Bill, station manager. Not pictured in the photos is the station’s dog mascot, “monoball”, so named explained John Barsic, because it had lost a testicle in a scrap with another island dog.

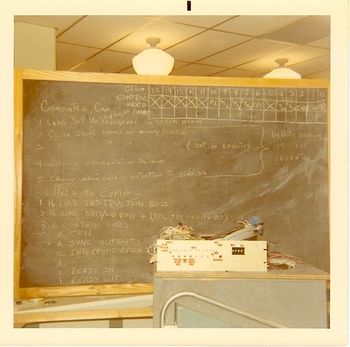

The contract provided for a week of installation and training support in which time we had to assure that the system arrived in satisfactory working order, integrate it with their legacy equipment, demonstrate its operation, and teach as much theory of operation as possible. John Barsic especially wanted to learn as much as he could about the workings of the 1126A, since that was the heart of our system. To that end we used their chalk board to detail operational concepts as exampled in Fig 13 showing computer interface operation for the 1126A Decom.

John was the one who came to Fort Washington for system acceptance and always evinced a strong interest in design concepts and logic and circuit operation. To that end he asked if I would mind extending my work day into the evening, which was fine with me as there’s not much to do after hours on a strip of sand a mile long by 500 yards wide.

John was particularly interested in understanding the circuit and logic design of the 1126A. since he would be responsible for operating and maintaining the equipment and the 17-hour time difference between Kwajalein and Fort Washington, PA allowed only a 2-hour voice communication window at the end of the workday in Fort Washington. TWX (teletypewriter exchange) was the only widely available non-voice communications medium, limited to 10 characters per second, highly constraining for discussing any technical or operational issue.

We met after hours in John’s quarters going over the 48 sheets of schematic for the decom unit in functional areas he was keen to understand. One of the night study sessions was shortened when John suggested I might want to be outside at a certain time. There was going to be a test firing from Vandenberg of an ICBM whose reentry vehicle (RV) with dummy warhead would be impacting in the Kwajalein lagoon about 26 minutes after its launch.

The accompanying photo, Fig 14 shows a single reentry vehicle descending to the lagoon. This is not my photo but one of many available online but does match my memory of a single RV. There were clouds which lit up from the white heat of reentry, illuminating the nearby buildings and seascape. Thus did I “see the light” on Ennylabegan and realize I had a foretaste of what it would look like if we were ever to experience a nighttime, nightmare ICBM strike.

We left Ennylabegan for Kwaj Wednesday of the second week to catch a MATS flight to Honolulu, staying overnight to catch the next day’s eastbound flight to LA and then a red eye back to Philadelphia.

Thursday morning before leaving the hotel in Honolulu, I called home to my newlywed wife, Bernadette, and we talked for about 45 minutes, the bill for the call coming to about $145. When I submitted my expense report no one objected to it.