Barrel Boring

This article was initially written by Robert Woods, ASME Fellow. This article contains material published in Mechanical Engineering Magazine May. 2007. Copyright 2007 American Society of Mechanical Engineers

The English got a rude surprise in 1429 at the siege of Orleans. They found that a French marksman named Jehan de Montesiler had some kind of hand cannon capable of picking off individual soldiers. He did this at the extreme range of arrows and was so sure of his advantage that to amuse himself he taunted the besiegers by occasionally lying down and pretending to be dead. The entire episode was a shock to the English. It is now recognized as the earliest documented use of handheld firearms in Europe.

The petard, which was a form of shaped charge, and the cannon, had been around for perhaps a hundred years, but a gunpowder weapon small enough to be managed by one man was something new. After 600 years, the siege of Orleans might be forgotten as just another one of the innumerable skirmishes between Britain and the Continent except for its most famous participant, Joan of Arc will not be forgotten. Two hundred years later, she was still getting bad press in Shakespeare's England. Our own Mark Twain was fascinated by her.

But a present-day technician might find more mundane aspects of the siege interesting-specifically, that famous gun. We might wonder: In the 15th century, how did manufacturers drill a hole an inch or so in diameter and a few feet long, straight enough to launch a projectile, and how did they keep that hole parallel to the axis of an iron rod? The answer is that they didn't. There was more to it than simply drilling.

Their technology, primitive as it was, was the beginning of a discipline that flourished and is still being refined today. In the 15th century, it started with blacksmithing. Barrel making has gone on to evolve the complex machine tools that are now used in such familiar products as heat exchangers and gasoline engines.

Evolving the Deep Bore

Cannon boring was a technology already well understood decades before the siege of Orleans. A cannon barrel began as a casting having a cavity large enough to allow the use of a robust boring bar. The machining of smaller bores such as musket barrels posed a different problem. It did not begin with a casting, and bores had to be kept within closer tolerances on diameter, smoothness, and straightness. Although daunting, those problems must have been solved, to some extent, before the siege.

The art of making gun barrels by hand reached an apex three centuries later, when the long rifles made in America were accurate enough to hit targets at distances of 200 yards. The technology advanced further only when powered tools appeared.

Simple as the finished product may look-after all, it is only a cylindrical hole--it has taken a century to evolve the complex powered drilling equipment that is used today to produce a deep bore. Metallurgy has also evolved. It now includes a spectrum of alloys, which can be chosen for properties such as strength, wear or corrosion resistance, and machinability.

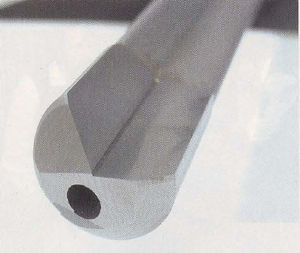

Modern tools only distantly resemble the familiar twist drill and they require highly specialized support equipment. Each feature in a range of geometries serves a different purpose, but common to them all is one or more bores through which high-pressure lubricant is injected. This feature lubricates the drill and eliminates the need to extract and replace it for chip removal. Gun drills such as these depend on lubricant pumps and rotary feedthroughs that allow delivery of fluid through the drill stem.

In addition to high-pressure lubrication, an external bushing is a critical new feature. This is a collar that steers the drill until the bore is deep enough to be self-guiding. Present-day practice sometimes involves rotating a raw gun barrel around the bore axis, while the cutting tool is rotated in the opposite direction. This allows slower rotation of the drill itself and reduces dynamic effect (bowing or "belling") of the rod. All of this highly evolved technology has found uses other than fabricating gun barrels, but the term "gun drilling" still refers to any application that involves long straight holes.

Even with present-day precision, a drilled bore will deviate from the desired axis by as much as several thousandths of an inch per foot. Such a runout is accommodated by drilling the bore as closely as possible to the axis of an oversize cylinder, centering the rough barrel on the axis of the bore-wherever it is-and then turning the outside diameter parallel. Gun makers did not have this convenience before the 18th century, when powered lathes became available. Until then, gunsmiths dealt with the fact that they could only file long surfaces flat. They finished the outside of gun barrels by hand-filing them to an octagonal cross-section, a process that would be done today by indexing heads and milling machines.

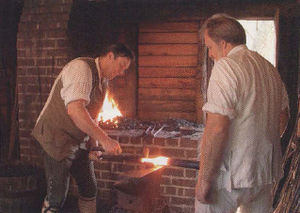

Early gun makers were forced to rely upon a number of handicrafts. The first stage of barrel making involved blacksmithing. A flat rectangle of iron was formed by hammering it to a thickness a little greater than the wall thickness of a finished barrel. It was then shaped into a tube by hammering the blank into an anvil that had a semi-cylindrical channel that was the outside diameter of a barrel.

The bore was formed by continually rotating the blank on the anvil while hammering it around a mandrel smaller than the finished bore. A number of reheats were required, during which care was taken to keep the mandrel at a lower temperature than the plate to prevent it from being welded in place.

After forming it into a tube, the smith welded the long edges of the plate into a seam that ran the full length of the barrel. The rough bore, formed when the mandrel was removed, served as a pilot for drilling. It was this that ensured that the finished bore and barrel would remain concentric. Since the forged bore was not large enough to allow use of a cannon's boring bar, a series of bits of increasing diameter were run through the barrel.

Colonial Williamsburg in Virginia has a gunsmithing program in which craftsmen work with a replica of a Colonial barrel drill. One man turns the drill itself, which does not move axially, while another feeds the barrel into the drill. The barrel is constrained by an elegant system of guides.

The Damascus Barrel

Chip removal required frequent extraction and reinsertion of bits. In Europe, straightness was sometimes checked by running a taut wire down the barrel and sighting on it through the bore. Bends were removed by hammering straight. Remarkably, such a process produced a passable barrel.

A variation on the usual forming technique was the Damascus barrel. A tube was formed by wrapping and hammer-welding strips of steel around a mandrel. The process substituted a series of helical welds for a single longitudinal one. Such barrels were prized at one time because of the decorative effect that could be achieved by acid etching. They fell out of favor very abruptly when smokeless powders were introduced. Damascus barrels had an unfortunate tendency to burst under the higher pressure of the new powders.

After drilling, bores were hand-reamed to a smooth finish. Craftsmen in the Colonial Williamsburg Gunsmithing Program have recently found that by using replica hand tools it is possible to ream a bore to diametral tolerances within 0.0005 inch. This is a respectable degree of precision even by modern standards, and another example of the results that can be achieved by metal workers who are true artists. In the case of rifles, grooves were produced by a metal cutting tool held on a wooden rod and steered by a hand-wrought helix.

Rifling was done in a number of passes and depth of cut was progressively increased by thin shims inserted between the tool and the holder. This process was well known as early as 1525.

It was rifling that brought firearms out of the primitive smooth-bore state and started them toward the status of precision machinery. Today, rifling is produced by a variety of processes. Some involve cutting each groove individually. In others, an array of grooves is formed by a single broaching or swaging operation. Many variations exist. For example, it has been found that an entire bore, along with rifling and an enlarged cartridge chamber, can be formed around a single mandrel by hammer-forging.

The first guns in the American colonies were smooth bore matchlocks brought from Europe. Around 1622, they began to be replaced by the snaphaunce, an early form of flintlock, also made in Europe.

Making the Long Rifle

Later, when gunsmithing began in the colonies, it consisted only of assembling imported parts because gunsmiths, working in individual shops, were incapable of competing with the facilities that existed in England. In 1740, there were 21 different gunsmithing trades there, each specializing in producing a single component. The usual practice was for a shop to maintain a prototype of its specific part, which the craftsmen attempted to duplicate by hand.

It was not until about 1840 that interchangeable parts were finally being manufactured, using fixtures that had been proposed in 1800 by Eli Whitney, but which he had not immediately introduced to practice. Rifles were ultimately produced in quantity, but they did not reach true mass production until the end of the Civil War when the accuracy of the rifle brought about changes in military tactics. When mass production arrived, a gun barrel ceased to be the product of an individual artist.

The long rifle, which typically had a barrel nearly 4 feet in length, was a crowning achievement in the art of gunsmithing. It was an American innovation of the 1700s, the product of a century-long evolution. Those rifles required a great deal of craftsmanship to produce; they were labor intensive, but the effort repaid the investment.

Pioneers had learned to depend on hunting rifles to provide meat for their tables. The American long rifle was one of the finest examples of the precision that could be attained by craftsmen who worked with hand tools and were armed only with their versatility and ingenuity. Probably only clockwork was a more demanding example of metalworking.