Synthetic Fuels

The original version of this article was created by Francesco Gerali, 2019 Elizabeth & Emerson Pugh Scholar in Residence at the IEEE History Center

It is recommended this article be cited as:

F. Gerali (2019). Synthetic Fuels, Engineering and Technology History Wiki. [Online] Available: https://ethw.org/Synthetic_Fuels

Early development of synthetic fuel production technology in Germany (1910s-1940s)

The beginning of the history of synthetic fuels datesgaso to 1913 when the first process of direct coal liquefaction (DLC) by mean of hydrogenation was patented in Germany by the chemist Friedrich Karl Rudolf Bergius (1884-1949)[1]

The basic principle of DLC was the use of coal instead of petroleum/crude oil to obtain liquid hydrocarbons used for fuel or as a base for producing other chemicals. The products obtained through this process were defined as synthetic because the coal feedstock undergoes different stages of heating, cooling, pressure, catalysis, enrichment, gasification and finally liquefaction.

The Bergius process allowed the conversion of coals, tars, and other solid or liquid carbonaceous substances into high-grade liquid fuels through the combination of large quantities of hydrogen from 200 to 700 atmospheres pressure (equivalent to 2939 psi - 10287 psi, or 2.027e+7 pa - 7.093e+7 pa) and high temperatures between 400° and 600° C (392° F - 1292° F), in the presence of catalyst agents like tin oxalate-ammonium chloride, or tungsten sulphide and nickel sulphide. In 1914 Bergius, supported by the chemical company Th. Goldschmidt AG, who understood the potential of his patent and offered their facilities, sought to give practical application to his patent. A substantial production started in 1919, after five years of discouraging experiments, improvements, trials and errors.

The technology required was still far away from being considered efficient. There were many technical flaws and in the beginning results were modest and costly. However, with the strained German post-World War I economic and geopolitical environment led to a the heavily decreased energy potential, which created a fertile ground for the young and still imperfect synthetic fuel technology. Germany had few petroleum deposits and a small and disorganized petroleum entrepreneurship who received little credit from the banking and financial environment. Refining, on the other hand, was the flagship of the German petroleum sector, but the harsh terms of capitulation limited Germany’s ability to purchase oil abroad. This motivated the government to finance research to maximize the abundant reserves of soft brown coal (lignite), hard brown coal, anthracite, non-cooking coal, and mainly bituminous coal. By the 1920s, new improvements to the methods of hydrogenation and catalysis initially developed by Bergius were patented in Germany, which were suitable to produce precious high-grade motor gasoline and aviation fuel.

In 1918, while Bergius was still working on the finalization of his production project, another groundbreaking process was developed by the chemists Fritz Haber (1868-1934)[5] and Carl Bosch (1874-1940).[6] The Haber-Bosh process entailed the synthesis by catalytic formation of ammonia from nitrogen and hydrogen at high pressure and temperature. Ammonia cannot be classified as a synthetic fuel, but it was the basic chemical for producing fertilizers and explosives. In the following decades, many of the chemical corporations producing synthetic fuels were also ammonia producers. Regardless of the differences in the production processes, investments in fuels and ammonia intersected and moved along in the development of the shared knowledge that dramatically improved the production methods to obtain large quantities of hydrogen from coal at low cost. The groundbreaking know-how and practices to handle techniques for industrial operations at high pressures, and the shaping of cadres of German scientists mastering in catalysts (science of materials) and catalysis dynamics (applied chemistry). The German postwar experiments on the production of gasoline from coal moved forward rapidly, and in 1921, within three years after the end of the war, the goal was successfully achieved.

A few years later, in 1925 at the Kaiser-Wilhelm Institut für Kohlenforschung (Institute of Coal Research) in Mülheim an der Ruhr (North Rhine-Westphalia, the strategic mining Ruhr area close to Duisburg and Essen), the chemists Franz Joseph Emil Fischer (1877-1947) and Hans Tropsch (1889-1935) developed a process to yield liquid hydrocarbons by combining a mixture of carbon monoxide (obtained breaking up by mean of steam coal molecules and passages of chemical enrichment) and hydrogen through metal catalysts (nickel, iron, cobalt, or ruthenium) at temperatures that may vary between 150° to 300° C (302°-572° F) and pressures up to 20 atmospheres (294 psi). The process, in theory, would have worked better on higher pressures, like the Bergius, but that would have resulted in a less effective energy cost-consumption balance, and the faster depletion of the catalyst. The Fischer-Tropsch process gave decisive momentum to the synthetic fuel legacy, and set the foundation toward the appealing and ambitious idea of a new age of ersatz, alternative fuels chemically derived and completely domestically produced. In the following years, the Fischer-Tropsch process proved to yield a high-grade diesel oil, but motor gasoline of low octane, and thus it never reached great importance for the liquid-fuel supply of Germany.

In the 1930s, the autocratic policy dictated by the Nazi regime, the need for large stocks of fuels “at any cost” in the view of the future conflict, generated the conditions for the boost of coal-based technology research and development for the mass production of synthetic fuels. All that was part of the Germany’s Four-Year Fuel Plan (1936-1940) aimed to triple the output of both conventional and synthetic fuels. The coal and chemistry industries received massive government support though it was more legislative rather than financial, and not always welcome. During those times several variations on the Bergius-hydrogenation and Fischer-Tropsch processes were developed, depending upon the different qualities of local coal and the metal catalysts employed. Names like Linde-Karawat, Koppers, Lurgi-Drawe, Winkler, and Schmalfeldt were some of the variations of Bergius and Fischer-Tropsch methods. The German chemical multinational I. G. Farben[7] was the first to develop efficient processes for mass industrial production. As a result of these processes, Germany could now obtain gasoline out of a coal mine, but more important in a political sense, it could now operate a mechanized army of tanks, bombers, and fighter planes with minimal natural petroleum.

The massive production of synthetic fuel required new laboratories and storage facilities, kilometers of pipes and thousands of ovens, conveyor belts, presses, compressors capable of reaching up to 4700 kilograms per square centimeter (some 10,500 pounds per square inch). This was no operation for small independent factories, since the initial capitalization could easily run into the tens of millions of Reichsmarks. Such operations required the facilities of the major German chemical giants like Ruhrchemie, I. G. Farben, and many other medium-large companies like Deutsche Erdol A.G. By the end of World War II, twelve industrial plants provided to the needs of the German military system.

However, despite the great scientific and industrial efforts, synthetic fuels remained a difficult and imperfect technology. The production process devoured large amounts of energy and minerals. The ratio feedstock weight/fuel yield was not in favor coal when compared to petroleum. Germany used its reserves and squeezed the technology down to the last drop regardless of the costs only to pursue its strategic objectives. The price of that goal was the implementation of an uneconomical and disadvantageous energy policy. On the other hand, and clear of any doubt, the scientific and technological wealth of knowledge, practices, procedures, and artifacts, developed in Germany between the 1910s and 1940s represents the foundations for the synthetic fuels production technologies still in current use around the world.

The German Legacy in the United States (1930s-1960s)

On other side of the Atlantic, the United States Bureau of Mines[8] first experimented with coal liquefaction by mean of hydrogenation on the Bergius process patent through a small-scale test unit built in 1937. This initial and inconsistent effort did not lead to any production, however it was precursor of the following, larger and much more ambitious, Synthetic Liquid Fuels Program, run by the same Bureau, aimed to create the technology to produce synthetic fuel from coal and also oil shale rocks on a commercial scale. The program was started in 1944 during World War II after the Synthetic Liquid Fuels Act, which authorized the use of $30 million US dollars over a five-year period for the construction and operation of demonstration plants. The goal was to produce synthetic liquid fuels in order to aid the war effort and to conserve and the oil resources of the nation. The United States authorities were notably impressed by the German technological endeavor which was allowing them to fight and prolong the conflict, virtually without crude oil. The awareness of the technological weakness in the available synthetic fuel technology at the time, and the related economic disadvantages, were counterbalanced by the optimistic expectations of research, development and implementation of the German processes to which American scientists were called upon to counter.

In 1945, the diminishing national oil reserves required the US to become an oil importer. The early liquefaction units were considered the forerunners of a new industry that would free the country from the dependence on foreign liquids. Between 1945 and 1948, new laboratories were erected near Pittsburgh, PA, and then the program was prolonged by eight years. By 1949 the plant could produce daily 200 barrels of synthetic crude. New facilities were built in 1951, but producing only 40,000 barrels of fuel until 1953. The same year the federal authorities abruptly ceased the funding for the research. The efforts did not bear the expected results so quickly as was hoped, and in mid-1950s the enthusiasm for a synthetic alternative was gradually replaced by the new streams of cheap and abundant oil from Middle East.

After eight years of hiatus, the U.S. government attempted another effort to develop the sinking coal mining activity, and that project included, even if only in minor extent, the resumption of the coal liquefaction projects. In July 1961, President Kennedy established the Office of Coal Research (OCR). This effort was established with the thought that the declining coal industry of 1960 could be revitalized and helping some of the United States' economically depressed areas. In fact, social goals as opposed to technical goals were the driving force behind this new technology development push in the country. Unfortunately, the necessary basic research to overcome the fundamental problems and the limiting gaps of the engineering economics in the production of the synthetic fuels was still not receiving enough funding and attention. A principal reason for this continued attempt to develop a technology more empirically rather than scientifically is linked to the purely social goals of the program. The program was designed to provide means for a short-term, quick, recovery of the coal industry and benefit to the demographic affected by its decline. A fully working technological option for the synthetic fuels production would have instead included a medium-long term and costly investment plan, which was not the real goal of the OCR.

Synthetic Fuel and Energy Crises in the United States (1970s-1980s)

Until the early 1970s, the development of synthetic fuel production technology in the United States has been discontinuous and marked by moments of advancement, limited interest, myopic policies and lack of funds. The attention on synthetic fuels experienced a resurgence with the tensions in the oil market during the 1970s. The existing chemical engineering technologies were quite reliable, but the real problem was the physical size of the few and little producing existing facilities, which were incapable of supplying the gap generated by the oil shortages started in 1973. The prices of conventional oil were considered the mobile target difficult to predict and hit, and the government authorities did not want to accept the risk of investing in the upgrading of facilities for synthetic oil that probably would have been not more strategic in the short time. At this point, in mid-1970s, the research and development for synthetic fuels in the United States, mainly planned and implemented by the Bureau of Mines, the Office of Coal Research, and other minor and short-lived agencies, produced neither commercial-scale synthetic fuel plants in operation or planning, or relevant advancements in comparison to the past German engineering effort which peaked in the 1940s.

The U.S. Congress created the Energy Research and Development Administration (ERDA) on October 11, 1974, in response to the Nation's growing need for additional sources of energy. The new agency would coordinate energy programs formerly scattered among many federal agencies, and serve as the focal point for a major effort by the Federal Government to expand energy research and development efforts. The Energy Research and Development Administration brought the major programs of research and development for all forms of energy together for the first time, and the research on synthetic fuels production technologies was considered a top priority. The Federal Government would have provided overall leadership and undertook only those efforts that industry could not initiate. As a technology approached the stage of commercialization, industry would have to assume the initiative. A sense of urgency ran through the plan, as the effort was formidable, the margin for failure was small, but the schedule would have to be adhered to if results were to be achieved and goals fulfilled. The short-term results would require an immediate expansion of existing energy resources and the implementation of conservation technologies, while mid-term results would require the establishment of a synthetic fuels industry.

The plan pushed the idea of a new synthetic fuels industry to create American energy independence and linked it to the American synthetic rubber experience during the Second World War. The effect of this explicit call to this source was the immediate growth of the studies published on synthetic fuels. Federal programs to assist industry in accelerating the commercialization of near-term technologies were a key element in the plan. The growing interest in the development of synthetic fuels as a mean of responding to looming shortfalls in oil and natural supplies took place in higher policy making circles. Synthetic fuels were now considered a strategic technology. In the 1975’s plan, they were inserted in the mid-term technology achievement category, but the truth was there were high expectations for the rapid improvement of existing technologies. Those expected new fuels were seen as the possible best substitute of gasoline, the price of which was close to tripling since 1973.

On August 4, 1977, President Jimmy Carter signed into law The Department of Energy Organization Act of 1977 which created the Department of Energy. The new agency, which began operations on October 1, 1977, consolidated the Federal Energy Administration, the Energy Research and Development Administration, the Federal Power Commission, and programs of various other agencies. Between 1974 and 1978, the governments of the Ford and Carter administrations in concert with several industrial partners embarked on the course of attempting to develop a number of synthetic fuel options as rapidly as possible. Due to the rush and the anxiety to achieve results rapidly there was again little opportunity to conduct fundamental, or base, research.

The result was that only the processes that had been under development in the previous era appeared to be viable as a course of action. In 1980, the Synthetic Fuels Corporation (SFC) was established by the Congress under the Energy Security Act. It represents a milestone in U.S. energy history, and the zenith for research and development financed with public money. The intended goal of the Synthetic Fuel Corporation was to boost the start-up, the implementation and the completion of commercially available processes for the production of synthetic fuels in great quantities. Congress did not leave the SFC financially impoverished in assisting in this task. With an $88 billion endowment to the SFC, the development of synthetic fuels became in that moment the driving national energy policy. Oil in 1980 burned out the symbolic threshold of $20 per barrel. In the light of that shocking number, every investment aimed to foster the national energy security was considered legitimate and necessary. The SFC looked to private industry to build a synthetic fuels industry yielding 500,000 barrels per day by 1987, a then ambitious short-term project, but considered necessary to test and assess the true reliability, effectiveness and long-term potential of the technology. The generous capital was endowed to corporations that would develop and build working technologies was supposed to be funded by a windfall-tax on excessive oil company profits.

The SFC was a challenge. Its goals were defined more on the desirable amount of fuel necessary to guarantee a safe supply rather than considering the available technology and the real chance of development. The SFC was to some extent a government-conceived gamble on the desired boost of the research and development system of the country. They were charged to break down the walls of the technological gap that was rendering synthetic fuels so inconvenient. From 1973 to 1980, the oil price multiplied 10 times, but in spite of that a gallon of traditional gasoline was cheaper that a gallon of synthetic.

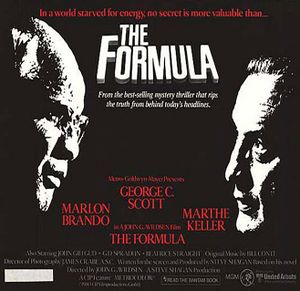

In 1980, even the civil society was perceiving this situation. The boundaries of the puzzling science and technology, the prerogative of selected cadres, were now colliding with popular science and the curious masses. The issues related to synthetic fuels – represented often in a bombastic way to the public as the panacea of all the energy disgraces – started to leak outside the laboratory and the experimentation plants. Even Hollywood rode the wave of the synthetic fuels question.

On Christmas 1980, American theaters projected the film The Formula. The cast featured two Academy Award winners, and played out a romance of Big Oil shady businesses, who hid the genuine and working German formula for forty years, to produce abundant and cheap synthetic fuels. Contemporary science knew very well that there was nothing hidden that could instantly solve the problem, as the original German synthetic fuel processes presented in the 1940s contained significant structural engineering gaps. The establishment of the SFC had a direct effect on the research on synthetic fuels.

The SFC in 1980 planned to reach its goal following a two-phase strategy. The emphasis during the first phase was on developing new fundamental experience with diverse basic technologies, meanwhile building the commercial base necessary to achieve the production goal. In the second phase, the SFC established a comprehensive production strategy to be implemented using the widest diversity of feasible technologies. All this was expected to happen in the very short term of five years.

However, 1981 unexpectedly turned out to be another 1953. The arrival of Ronald Reagan in the White House and the onset of a major oil boom again wiped out the political will and the economic justification for synthetic fuel production in government circles. In spite of the fact that the country paid at the end of the year the highest oil bill ever recorded, the administration quietly let the largest single domestic program passed in the United States up to that point expire by 1984, and it dispersed hardly any of its $88 billion in funds. Although the fundamental issue of reliance upon foreign petroleum for liquid fuels had not been solved in any permanent fashion, the alignment of interests between the Saudi monarchy and the United States, caused by the Iranian Revolution, the Iran-Iraq War, and the Soviet Invasion of Afghanistan, had been enough to bury and forget the oil shock under another lake of oil for the incoming future.

In 1981, politics won over research and science. The price to pay was the interim high cost of crude oil and refined products, which was expected to decrease in 1982 due to the new agreement between the U.S government and some exporter countries in the Middle East. Scientists found themselves powerless under the sabotage of the thriving Synthetic Fuels Corporation’s program that just in two years doubled the research on production technology in the attempt to meet the demands of the original 5-year timeline. The threat of funding cuts and loss of political favor were real. But, the projects that had already received grants and in-kind support were fully operative, maximizing time and resources.

In 1982, the most notable effect of the research thrust fueled by money and driven by the concern for the future, was the highest number of publications on synthetic fuel technology documented in the Department of Energy records. Unfortunately, the forecasts on crude oil prices and synthetic fuels in 1979-1980 came under time-sensitive pressure and led to technological miscalculation. Since the adjustment of oil prices started in 1982, experts began predicting more stable oil supplies and declining costs in the next several years. The SFC's targets for 1984 were to assist about a dozen projects which represented a diversity of resources and technologies in order to establish industry and environmental infrastructure to develop the management and manufacturing capability to assure that synthetic fuels would be available on time if and when they are needed.

From 1980 to 1984 more than 160 projects were evaluated and approved, but in 1985 almost 150 were turned down. With the 1984-1985 oil boom and the forecast of lower prices President Ronald Reagan signed the Consolidated Omnibus Budget Reconciliation Act of December 1985 (Law 99-272) into law, which among other things, abolished the Synthetic Fuels Corporation. The demise of the Synthetic Fuel Corporation in 1985, together with the dramatic reduction of the federal synthetic fuel research funding by more than 90% since 1981 (in 1974 dollars, from $377 to $20 million), and the post-1982 shut down of the major synthetic fuel research labs in industry, the United States ended its last synthetic fuel technology development thrust in this century without having demonstrated the commercial viability of mass production processes. At the end of 1986, neither government nor private industry had constructed a commercial-size coal liquefaction plant in the United States, and it is simply not known whether Direct Coal Liquefaction is a viable technology. Between 1986 and 1988, the oil prices stepped back to the pre-1980 levels and the premises of further prices reductions virtually erased any request for synthetic fuels in the short-medium term.

The final balance

More than six years after the creation of the SFC and almost one year after its demise, the program had produced no new synthetic oil, instead only controversy. On the other hand, for the first time in its energy history, the United States produced a great deal of knowledge on synthetic fuels

Between 1920s and 1960s, the development failure associated with synthetic fuel production technology in the United States is partly explained by: 1) the economics of the oil market, 2) the difficult coordination between private and public sectors, and 3) the politics of the energy crises. However, in the mid-1980s the scientific community recognized the damage that could be done by the discontinuous scientific and engineering activity associated with synthetic fuel technology. Subsequently, scientists understood how deleterious another hiatus would be. The development of efficient and commercial production of synthetic fuel in the United States has experienced several major hiatuses where little or no significant research, development, or demonstration was carried out, or where insufficient time and effort were devoted to the technology. These hiatus periods were the product of inconsistent public policy and underinvestment in basic research by industry and government, and had the result of limiting the sought after fuel replacement process.

In 1986, the situation was different. After twelve years of intensive research (1974-1985), it was understood that a further hiatus period would have irreparably wasted the results achieved with the nearly-completed research, development, and demonstration program. The discontinuous support or breaks in the process development cycle are critical factors that could undermine, for example, the information/knowledge survival rates. Both in private firms and government settings, information and knowledge regarding process technologies may be lost during prolonged periods of non-R&D activity. Another important loss factor is connected to the person-to-person knowledge transfer. When an R&D team is dismantled and assigned to new duties, the loss of information is high and disrupts the process of continuous incremental improvements.

When the U.S. Synthetic Fuels Corporation was abolished by law on April 18, 1986, the responsibility of monitoring the existing synthetic fuels project was transferred to the Office of the Secretary of the Treasury. In addition, on April 19, 1986, the Secretary established the Office of Synthetic Fuels to monitor, technically and environmentally, every federal synthetic fuel project.

The new energy wealth of the late 1980s was indelibly marked by the 1970s fears. The synthetic fuels were no more a feedstock of primary necessity, but rather a “spare tire to keep in the trunk”. The oil industry was divided over when oil prices would rise again and how they would last. The uncertainty made it difficult to know when, if ever, synthetics fuels will be profitable. The researchers still committed to the synthetic fuel challenge in the second half of the 1980s agreed on the necessity of long-term studies to achieve the base-research required to successfully experiment with new pioneering technologies. The short term project finalized to develop ready-to-go technology for immediate use did not pay off. On the other hand, it was now clear that resources allocated by the Synthetic Fuel Corporation a few years earlier were spread too thinly over multiple and uncoordinated projects.

There is no easy road to instant commercialization of new unconventional technologies. Research and development requires years of testing, billions of dollars in new capital and the construction of highly complex facilities. The attempted development of the synthetic fuels production technology was a failure mostly because of overemphasis on a quick-fix development program rather than on the necessary basic research aimed to fix the structural flaws left by Germans engineers 40 years earlier.

References

Anderson, L. & Tillman, D. Synthetic Fuels from Coal: Overview and Assessment. New York: Wiley, 1979.

Atwell, H. V. Report on investigation of synthetic lubricating oil plant, Rheinpreussen, Homberg / reported by H. V. Atwell, W. C. Schroeder. Washington, D.C.: Office of the Publication Board, Dept. of Commerce, 1945.

Bourji, A. K. Coal Gasification: an Alternate Source of Energy. Doctoral Dissertation. Lamar University, 1985.

Cowan, B.W. & Stover, E. L. “Petroleum Processing and Synthetic Fuels”. Water Pollution Control Federation 56, no 6 (1984): 651-654.

Blossfeld, H. & Rohwer, G. Techniques of Event History Modeling: New Approaches to Casual Analysis. New York: Taylor & Francis, 2002.

Buck, A. A History of the Energy Research and Development Administration. Washington: U.S. Department of Energy – Office of History and Heritage Resource, 1982.

Bunneil, R. “The Fragile Future of Synthetic Fuels”. Nation's Business 72 (1984): 42.

Clewell, D. “Petroleum Research and the future”. Economics of the Petroleum Industry 1 (1963): 4-23.

Copulos, M. “Salvaging the Synthetic Fuel Corporation.” The Backgrounder 423 (1985): 1-4.

Crow, M. Synthetic Fuel Technology Development in the United States: A Retrospective Assessment. New York: Praeger, 1988.

Dewey, D. R. Wartime research on synthetic fuels: Kaiser Wilhelm Institute fuKohlnforschung. Washington, D.C.: Dept. of Commerce, 1946.

Edewor, J. O. Production and Utilisation of Synthetic Fuels. An Energy Economics Study. Manchester: The University of Manchester Institute of Science and Technology, 1979.

Goodger, E. M. Alternative Fuels: Chemical Energy Resources. New York: Wiley, 1980.

Green, E. K. Economic Efficiency of Three Synthetic Fuel Processes. Lexington: University of Kentucky, 1977.

Hamilton, J. D. “Historical oil shocks,” In Routledge Handbook of Major Events in Economic History, edited by R. E. Parker and R. M. Whaples, 239-265. New York: Routledge, 2013.

Harlan, J. K. Starting with Synfuels: Benefits, Costs, and Program Design Assessments. Cambridge: Ballinger, 1982.

Hendrickson, T. A. & Cameron Engineers. Synthetic Fuels Data Handbook: Green River Oil Shale, U.S. Coal, Alberta Oil Sands. Denver: Cameron Engineers, 1975.

Hoffman, E. J. Synfuels, the Problems and the Promise. Laramie: Energon, 1982.

Hughart, D. P. (1977). Synthetic Fuel and Electric Cars: A Cost-Effectiveness Comparison of Alternatives for Substituting Coal for Oil. University of Michigan. Master Thesis.

Landsberg, H., Schanz, J. Jr, Schurr, S, Thompson, G. (1974). Energy and the Social Sciences. Washington D.C.: Resources for the Future, Inc.

Lee, B. S., & American Institute of Chemical Engineers. (1982). Synfuels from Coal. New York: American Institute of Chemical Engineers.

Mahmoudi, Hamid & Mahmoudi, Maedeh & Doustdar, Omid & Jahangiri, Hessam & Tsolakis, Athanasios & Gu, Sai & LechWyszynski, Miroslaw. A review of Fischer Tropsch synthesis process, mechanism, surface chemistry and catalyst formulation. Biofuels Engineering 2 (2017). 10.1515/bfuel-2017-0002.

Matar, S. (1982). Synfuels: Hydrocarbons of the Future. Tulsa: Penn Well Books.

Marshall, E. “The Synthetic Fuels End Game”. Science 223, 4633 (1984): 260.

Meyers, R.A. Handbook of Synfuels Technology. New York: McGraw-Hill, 1984.

Orth, C. D. Administering research and development; the behavior of scientists and engineers in organizations. Homewood: Richard D. Irwin, 1970.

Polaert, T. J. (1985) “Status of German Coal Conversion Technology”. Chemical Economy and Engineering Review 17, 3 (1985): 12-22.

Probstein, R. F., and Hicks, R. E. Synthetic Fuels. McGraw-Hill Chemical Engineering Series. New York: McGraw-Hill, 1982.

Rocks, L. Fuels for Tomorrow. Tulsa: Penn Well Books, 1982.

Shadish, W. R.; Cook, T. D.; Campbell, D. T. Experimental and Quasi-Experimental Designs for Generalized Causal Inference (2nd ed.). Boston: Houghton Mifflin Company, 2002.

Standard Oil Company of New Jersey. Gasoline by synthesis. New York: The Company, 1946.

Stranges, A. N. “From Birmingham to Billingham: High-pressure coal hydrogenation in Great Britain”. Technology and Culture 26 (1985): 726-757.

Stranges, A. N. "Synthetic fuel production in prewar and World War II Japan: A case study in technological failure." Annals of Science 50 (1993): 229-265.

Stranges, A. N. “The US Bureau of Mines' Synthetic Fuel Programme, 1920-1950's: German connections and American advances.” Annals of Science 54 (1997): 29-68.

Striner, H. E. An analysis of the bituminous coal industry in terms of total energy supply and a synthetic oil program. New York: Arno Press, 1979.

Szyliowicz, J. & O’Neill, B. The Energy Crisis and the U.S. Foreigner Policy. New York: Praeger, 1975.

Topper, D. Quirky sides of scientists: true tales of ingenuity and error from physics and astronomy. Springer E-Books. New York: Springer, 2007.

United States, Bureau of Mines. Synthetic liquid fuels / annual report of the Secretary of the Interior for 1949. Washington, D.C.: U.S. Dept. of the Interior, Bureau of Mines, 1950.

United States, Congress. Synthetic Gasoline: Hearing before a Subcommittee of the Committee on Government Operations, House of Representatives, Ninety-fourth Congress, First Session, September 23, 1975. Washington, D.C.: U.S. G.P.O., 1975.

United States, Congress. Loan Guarantees for Commercial-size Synthetic Fuels Demonstration Plants: Hearings before the Subcommittee on Energy Research, Development, and Demonstration (Fossil Fuels) of the Committee on Science and Technology, U.S. House of Representatives, Ninety-fourth Congress, First Session. Washington, D.C.: U.S. G.P.O., 1975.

United States, Congress. Synthetic Fuels Corporation Oversight: Hearing before a Subcommittee of the Committee on Government Operations, House of Representatives, Ninety-seventh Congress, First Session, February 19, 1981. Washington, D.C.: U.S. G.P.O., 1981.

United States, Congress. SFC Oversight: Goals of the Reagan Board of Directors: hearing before a Subcommittee of the Committee on Government Operations, House of Representatives, Ninety-seventh Congress, First Session, September 17, 1981. Washington, D.C.: U.S. G.P.O., 1981.

United States, Congress. Synthetic Fuels Environmental Research and Development: Hearing before the Subcommittee on Energy Development and Applications and the Subcommittee on Natural Resources, Agriculture Research, and Environment of the Committee on Science and Technology, U.S. House of Representatives, Ninety-seventh Congress, First Session, October 1, 1981. Washington, D.C.: U.S. G.P.O., 1982.

United States, Congress. Synthetic Fuels Industry in Today's Economic Climate: Hearing before a Subcommittee of the Committee on Government Operations, House of Representatives, Ninety-seventh Congress, Second Session, June 9, 1982. Washington, D.C.: U.S. G.P.O., 1983.

United States, Congress. Examination of Procedures by Which the Synthetic Fuels Corporation Selects Projects for Federal Financial Assistance: Hearing before a Subcommittee of the Committee on Government Operations, House of Representatives, Ninety-eighth Congress, First Session, December 8, 1983. Washington, D.C.: U.S. G.P.O., 1984.

United States, Congress. Synthetic Fuels Corporation Oversight: Hearing before a Subcommittee of the Committee on Government Operations, House of Representatives, Ninety-eighth Congress, Second Session, May 16, 1984. Washington, D.C.: U.S. G.P.O., 1985.

United States, Congress. Synthetic Fuels Policy: Hearing before the Subcommittee on Fossil and Synthetic Fuels of the Committee on Energy and Commerce, House of Representatives, Ninety-ninth Congress, First Session, on H.R. 935, a Bill to Abolish the United States Synthetic Fuels Corporation, to Reduce Federal Deficits, and for Other Purposes; Together with a Dialog on the Synthetic Fuels Corporation Held March 29, 1985; April 24, 1985. Washington, D.C.: U.S. G.P.O., 1985.

United States, Congress. U.S. Synthetic Fuels Corporation's Proposal to Award the Great Plains Project $820 Million in Additional Federal Financial Assistance: Hearing before a Subcommittee of the Committee on Government Operations, House of Representatives, Ninety-ninth Congress, First Session, May 22, 1985. Washington, D.C.: U.S. G.P.O., 1986.

United States, Federal Energy Administration and National Science Foundation. Spurring synthetic fuel production. Washington: Published jointly by Don Sowle Associates, Inc., Arlington, Va. and the Graduate School of Business, University of Texas at Austin, 1975.

Yanarella, Ernest J., and Green, William C. The Unfulfilled Promise of Synthetic Fuels: Technological Failure, Policy Immobilism, or Commercial Illusion. Contributions in Political Science, No. 179. Westport, Conn.: Greenwood Press, 1987.

See Also

Further Reading

- ↑ https://www.nobelprize.org/prizes/chemistry/1931/bergius/biographical/

- ↑ http://www.edumine.com/xtoolkit/xmlwords/xmlwords.htm

- ↑ http://www.edumine.com/xtoolkit/xmlwords/xmlwords.htm

- ↑ http://www.edumine.com/xtoolkit/xmlwords/xmlwords.htm

- ↑ https://www.nobelprize.org/prizes/chemistry/1918/haber/biographical/

- ↑ https://www.nobelprize.org/prizes/chemistry/1931/bosch/biographical/

- ↑ https://www.europeana.eu/portal/en/search?q=I.+G.+Farben+

- ↑ https://www.mininghistoryassociation.org/Journal/MHJ-v13-2006-Kaas.pdf

![Lignite[2]](/w/images/thumb/d/d8/Lignite.jpg/120px-Lignite.jpg)

![Anthracite[3]](/w/images/thumb/2/2e/Anthracite.jpg/120px-Anthracite.jpg)

![Bituminous coal[4]](/w/images/thumb/6/67/Bituminous_coal.jpg/120px-Bituminous_coal.jpg)