Jet Fuel

The original version of this article was created by Francesco Gerali, 2019 Elizabeth & Emerson Pugh Scholar in Residence at the IEEE History Center

It is recommended this article be cited as:

F. Gerali (2019). Jet Fuel, Engineering and Technology History Wiki. [Online] Available: https://ethw.org/Jet_Fuel

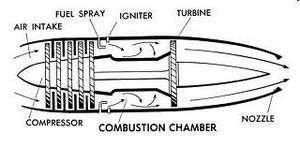

In aviation, the propulsion by mean of an aviation gas turbine engine (jet engine) powered with jet fuel is a forward movement generated by the rear ejection of a high-speed heated flux/jet of combustion gasses. The first jet engines were developed between 1939 and 1941 in Germany[1] and Great Britain.[2] The early experimental flights were accomplished by burning hydrogen, gasoline, diesel, and kerosene for illumination. Eventually, only lamp kerosene and car gasoline were used in the final prototype flights. However, gasoline presented a major problem: at the time, it had a low flashpoint[3] which made fires much more likely in case of accident.

Another relevant issue with gasoline was its low rate of vaporization, the property of a liquid fuel to turn into a gaseous state. In light of those issues, kerosene was eventually chosen as a base fuel for the new path in the engineering of aviation fuels. Soon it was understood that the advancement of aviation turbine technology required the development of a new generation of fuels that are effective in addressing the new issues that emerged with the new challenges posed by increased flight speed and altitudes. Early jet engines were more tolerant than gasoline and diesel engines, but they were still sensitive to the chemical and physical properties of the fuel. The aviation turbines could not burn everything, as someone speculated at the beginning of the jet engine era.

Early advances in engine and aircraft design greatly expanded the new jet science discipline. This led to the introduction of a variety of kerosene types for different purposes and to the development of specifications to ensure that the fuel met requirements under all flight conditions. Early jet fuel technology was exclusively a military business. Much of the efforts and early discoveries were made by the German (advanced knowledge on coal derived synthetic fuels), British and American air forces. In the 1950s, all the jet fuels for commercial aviation were derived from early jet military technology.

In the 1940s, the first standards for the freezing point (a lower one was needed because the increasing of the operational altitudes) and the need for higher flashing points for the new jet fuels - named also aviation turbine fuel (ATF) were established. The first jet fuel was known as JP-1 (Jet Propellant 1) and was a blend of gasoline, kerosene and other chemicals. U.S. military research laboratories soon sought fuels with better qualities, like those that did not produce visible smoke nor contrails (the visible trail of condensed water vapor, or ice crystals, caused by the condensed water exhausted by planes at given altitudes). However, the major requirement that occupied chemists was the need for a kerosene that did not ignite at low temperatures to reduce the chance of fire. The following decades saw continuous improvements to the numerous jet propellants produced through the increasing blending of chemical agents.

Jet fuel is a high-quality and very purified fuel that can be optimized (depending on the final user's specific needs) with solvents to remove or reduce the levels of undesirable components (e.g. sulfur, nitrogen or olefinic materials) that may cause the buildup of contaminants in the engines and seriously affect performance and flight safety (like carbon deposition in the afterburner fuel lines)[4]; anti-freeze to prevent ice buildup inside the fuel tanks; agents that prevent aviation fuel becoming electrically charged; and also additives that inhibit the growth of organic matter in the aviation fuel tanks.

Other special additional processing reduces compositional variation and enriches components that improve performance (like the cycloalkanes[5] and isoalkanes[6]). When a stock of jet fuel fails the purity and other quality tests for the use on a jet plane, it is then diverted to the ground transportation market, which has less demanding requirements. Jet fuel is generally cheaper than regular gasoline, but more than other fuels, and it is subject to very comprehensive, strict, and internationally standardized quality specifications.

Research on jet fuels was not only aimed to optimize the petroleum-based kerosene rich in alkanes. In the past three decades successful studies were conducted, especially in the United States, to develop coal-based jet fuel rich in cycloalkanes and hydroaromatics.[7] Responding to the results achieved in the 1980's by USSR military aviation in the production of fuels rich in cycloalkanes, or naphthenes, (carbon atoms linked in rings cycloalkanes have higher volumetric energy density (MJ/L) than alkanes) a joint government-academia-industry research project in Pennsylvania developed a coal-based fuel made of thermally stable molecules from coal, together with compounds from petroleum, rich in cycloalkanes and with superior performances.

A different set of research has been also developed on renewable feedstock like biokerosene based on algae or biofuels from jatropha[8] and camelina oil.[9] There are several processes to convert vegetable oils into jet fuel, but the best developed and tested is hydroprocessing,[10] which adds hydrogen in order to remove the oxygen in excess and then complete the process to meet the needed specifications. Renewable aviation fuels are different from traditional petroleum-derived jet fuel, but they are molecularly identical and can be normally used in existing jet engines without any further treatment or enrichment meeting the same performance criteria as traditional fuels.

See also

References

Anonymous. “Jet Fuel Developed under German Process”. The Science News-Letter 67, no 26 (1955): 410.

Coordinating Research Council. Handbook of Aviation Fuel Properties. Atlanta, Ga.: The Council; Warrendale, Pa.: Society of Automotive. 1983.

Martel, Charles R. Military Jet Fuels, 1944-1987. Washington: Government Printing Office, 1987.

McFarland, Stephen L. "Higher, Faster, and Farther: Fueling the Aeronautical Revolution, 1919-1945." in Launius, Roger D., ed. Innovation and the Development of Flight. College Station: Texas A&M University Press, 1999.

Kaltschmitt, Martin, and Ulf Neuling. Biokerosene Status and Prospects. Berlin, Heidelberg: Springer, 2018.

Perret, Geoffrey. Winged Victory: The Army Air Forces in World War II. New York: Random House, 1993.

Smith, Hugh. "Jet Aircraft of World War II." The Air Power Historian 9, no. 3 (1962): 166-72.

Sweeney, W.J. “Research on Hydrocarbon Fuels for Aircraft Propulsion”; Sweeney, W.J. “Petroleum: Its Use for Motive Power”; Tsien, Hsue-Shen. “Possibilities of Atomic Fuels for Aircraft Propulsion Power Plants”, in: Aircraft Fuels and Propellants, A Report Prepared for the AAF Scientific Advisory Group, edited by William Joseph Sweeney; USA Army Air Forces Scientific Advisory Group. Wright Field, Ohio: Headquarters, Air Materiel Command. May 1946.

Further Reading

- ↑ http://www.aviation-history.com/heinkel/he178.html

- ↑ https://www.aerosociety.com/media/4852/the-gloster-e28-39-fin-arrangement-and-spinning-characteristics.pdf

- ↑ http://large.stanford.edu/courses/2014/ph240/ukropina2/

- ↑ https://engineering.purdue.edu/~propulsi/propulsion/jets/basics/afterburner.html

- ↑ https://chem.libretexts.org/Courses/Athabasca_University/Chemistry_350%3A_Organic_Chemistry_I/Chapter_4%3A_Organic_Compounds%3A_Cycloalkanes_and_their_Stereochemistry/4.1_Naming_Cycloalkanes

- ↑ https://chem.libretexts.org/Ancillary_Materials/Reference/Organic_Chemistry_Glossary/Isoalkane

- ↑ https://www.merriam-webster.com/dictionary/hydroaromatic

- ↑ https://www.sciencedirect.com/topics/chemistry/jatropha

- ↑ https://plants.usda.gov/plantguide/pdf/pg_casa2.pdf

- ↑ https://www.aiche.org/academy/videos/conference-presentations/tutorial-on-hydroprocessing-ihydroprocessing-catalysts-and-processesi