First-Hand:The X-2 - Chapter 8 of The Experimental Research Airplanes and the Sound Barrier: Difference between revisions

| Line 26: | Line 26: | ||

[[File:13. Langley Lab First wind tunnel.jpg|thumbnail|left|Langley Laboratory’s first wind tunnel went operational in 1920. NACA photo]] | |||

The first NACA research airplanes were nothing other than two WW I two-place Curtiss JN-4H (Jenny) training airplanes. The engineers had to devise special airplane instrumentation to measure and record such quantities as propeller thrust, precise speed, angle of attack, yaw angle, pilot control forces, and control surface deflections. Thus a group of specialized instrumentation engineers was born. The NACA technical report that described the flight testing and comparison with wind tunnel testing also noted the need for specially educated engineering test pilots to conduct the flight testing. One of the next subjects of flight testing was the measurement and recording of air pressure distributions across airplane wing and control surfaces, not only in level flight but also in accelerated maneuvers. [2 pp.2-5] [52, p.16] | The first NACA research airplanes were nothing other than two WW I two-place Curtiss JN-4H (Jenny) training airplanes. The engineers had to devise special airplane instrumentation to measure and record such quantities as propeller thrust, precise speed, angle of attack, yaw angle, pilot control forces, and control surface deflections. Thus a group of specialized instrumentation engineers was born. The NACA technical report that described the flight testing and comparison with wind tunnel testing also noted the need for specially educated engineering test pilots to conduct the flight testing. One of the next subjects of flight testing was the measurement and recording of air pressure distributions across airplane wing and control surfaces, not only in level flight but also in accelerated maneuvers. [2 pp.2-5] [52, p.16] | ||

Revision as of 17:53, 28 July 2016

By David L. Boslaugh, CAPT USN, Retired

Origin of NACA

As early as 1870 the Aeronautical Society of Great Britain was investigating the mysteries of flight with wind tunnels, and by the time of the outbreak of the Great War in 1914 France had three aeronautical research facilities including Gustav Eiffel’s wind tunnels in the base of his famous tower. Furthermore, in Germany at the time, three universities had aero research labs in addition to the government laboratory at Adlershof. Even though the U.S. had been first in flight in 1903, the country in 1914 had no such facilities comparable to the nations on the other side of the Atlantic. Even in 1911 knowledgeable American scientists, seeing the aeronautical knowledge lag behind the European powers, proposed that the Smithsonian Institution should restart the aeronautical research begun by Smithsonian’s aviation pioneer Samuel Pierpont Langley. This came to nothing, in part due to opposition by the military services. The Smithsonian persisted regardless and resurrected Langley’s lab staff whose first task was a comprehensive review of the state of aeronautical research at home and abroad. [2, p.i-ii]

The resulting study report was convincing enough for Congress to authorize and fund an Advisory Committee for Aeronautics in the 3 March 1915 Naval Appropriations Act. It called for an unpaid, except for expenses, group of twelve knowledgeable representatives from the Army, the Navy, the U.S. Weather Bureau, the Smithsonian, and the National Bureau of Standards plus representatives from academia, and private industry. A sum of $5,000 per year was authorized to cover committee expenses and to fund a small supporting staff. The stated mission was:

To supervise and direct the scientific study of the problems of flight with a view to their practical solution, and to determine the problems which should be experimentally attacked and to discuss their solution and their application to practical questions.

The congressional language also said that if a government aeronautics laboratory should be established, the committee would be authorized to direct the experiments and research in such a laboratory. [2, p.ii]

President Wilson made the initial Committee appointments on 2 April 1915, leading to the first Committee meeting on 23 April. The President asked Mr. Orville Wright to be a charter member. At the first meeting, the Committee elected Brigadier General George P. Scriven, chief of the Army Signal Corps, as chairman, and also decided to add the word “National” to its name. As a first order of business the Committee recommissioned another survey of government, academic, and industrial aeronautical research facilities. The survey report confirmed the paucity of such, and led to the committee’s first “advisory” to Congress; that the government should authorize, fund, and build an aeronautical research laboratory. [52, pp.9-10, 12-13] [2, p.ii]

As early as 1915, General Scriven, who was not only NACA Chairman but also Chief of Army Aviation, had established a team of six officers to survey sites throughout the nation that could be a home for an army aeronautical lab, a NACA research site, and also serve as the first operational Army airfield. The committee advised Scriven that the field should: be on the water to support navy testing, it should be flat and surrounded by clear unobstructed land to facilitate flight operations and future expansion, and it should be near an army base. The survey team visited fifteen sites in the eastern U.S. and as far west as Missouri. The six officers often dressed as hunters or fishermen to dampen ideas of land speculation if locals thought the government was interested in buying nearby property. Gen Scriven finally chose 1,650 acres having access to Chesapeake Bay near Hampton, Virginia, and so informed the Committee. [52. p.12-13]

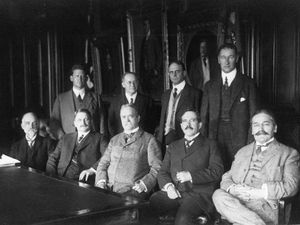

23 April 1915 saw the first meeting of the Advisory Committee for Aeronautics in the office of the Secretary of War. Standing from left to right: Holden C. Richardson, naval instructor; John F. Hayford, Northwestern University, Ill.; Capt. Mark L. Bristol, director of Naval Aeronautics; Lt. Col. Samuel Reber, Signal Corps. In Charge, Aviation Section. Seated: William Durand, Stanford University, Calif.; S. W. Stratton, Director, Bureau of Standards; Brig. Gen. George P. Scriven, chief signal officer, War Dept.; C.F. Marvin, Chief, United States Weather Bureau; Michael I. Pupin, Columbia University, NY. Present, but not in the photo: Joseph S. Ames, Johns Hopkins University, Baltimore, Md.; Hon. B. R. Newton, Asst. Secretary of Treasury. Charter member Orville Wright did not attend, but would be at later meetings. NACA photo

The Langley Laboratory

The Committee endorsed a request to Congress to authorize $87,000 in the fiscal year 1916 budget to build a NACA laboratory on a part of the new army airfield. It was so appropriated on 29 August 1916. The airfield was to be named after the Smithsonian’s aviation pioneer Samuel Pierpont Langley, and the new NACA facility would be called Langley Memorial Aeronautical Laboratory. The J. G. White Engineering Corporation of New York broke ground for the first laboratory building in July 1917. Because of the press of the U.S. entry into World War I, the Army had to hold its plans for an aeronautical research and testing facility in abeyance and used the field instead as one of 32 Air Service Training Camps. Other army uses included aerial observer’s school, balloon station, photography school, and an operational flying field for aerial coastal defense. During WW I, the Army did a small amount of experimental engineering work at Langley Field, but moved most aeronautical research to its engineering division at McCook Field near Dayton, Ohio. In May through July 1921 General Billy Mitchell used the field as his operating base when he proved that his 1st Provisional Air Brigade could sink repairated German battleships some 50 miles off the Virginia coast. [52, pp.13-14] [70]

By 1919, the NACA corner of Langley Field consisted of a small administration building, one wind tunnel building under construction, an engine dynamometer laboratory, and a warehouse. Total staffing was eleven engineers, mechanics, and administrators. The wind tunnel was to be similar to Gustav Eiffel’s tunnel having a five-foot diameter test section with a special insert that could reduce cross section to two and a half feet. The tunnel could provide speeds up to 120 mph, and was adjudged the fastest in the world, even faster than Eiffel's. Test model airplanes were suspended on wires in the tunnel and ordinary commercial weighing scales with balance arms were connected to the models to measure airplane lift and drag. Wind tunnel testing was one thing, but the question was how closely did extrapolated wind tunnel results represent real world airplane lift and drag. The next step would be to test instrumented airplanes in flight to determine their lift and drag characteristics for comparison. [52, p.14] [2, pp.2-3]

The first NACA research airplanes were nothing other than two WW I two-place Curtiss JN-4H (Jenny) training airplanes. The engineers had to devise special airplane instrumentation to measure and record such quantities as propeller thrust, precise speed, angle of attack, yaw angle, pilot control forces, and control surface deflections. Thus a group of specialized instrumentation engineers was born. The NACA technical report that described the flight testing and comparison with wind tunnel testing also noted the need for specially educated engineering test pilots to conduct the flight testing. One of the next subjects of flight testing was the measurement and recording of air pressure distributions across airplane wing and control surfaces, not only in level flight but also in accelerated maneuvers. [2 pp.2-5] [52, p.16]

By 1925 Langley staffing was up to 100 employees, and requests were coming from the military services and industry to undertake special investigations of numerous types of aircraft. Also in that year NACA headquarters in Washington authorized the lab to design and construct a 20-foot diameter “propeller research” tunnel that would be large enough to accommodate a full sized airplane fuselage with engine and propeller. It could achieve speeds of 110 mph and was the largest wind tunnel in the world. In the mid 1920s the U.S. Navy was tending toward use of radial engines in carrier airplanes rather than more streamlined in-line liquid cooled engines. Among other things, the service was finding that the rough carrier landings were springing leaks in liquid cooling systems. In 1926 the Navy’s Bureau of Aeronautics asked NACA if they could design a streamlining cowling for their flat nosed radial engines that would not only reduce cylinder drag but would also ensure the engines were adequately cooled. The new propeller research tunnel was a natural for testing the drag of a full sized propeller, cowling, fuselage combination. The final results were astounding when tested on a P-1A Army Curtiss Hawk fighter. At the same power setting the new cowling increased the speed from 118 to 137 mph, with hardly any increase in weight. The new cowling design received acclaim and immediate use throughout the aircraft industry. [2, p.8] [52, pp.17-18]

Another victory of the propeller research tunnel was proof that the drag of fixed landing gear constituted as much as 40% of total airplane drag, far more than industry thinking at the time. This clearly demonstrated the value of the additional weight and complexity of retractable landing gear. In another investigation, Langley engineers applied the drag reducing cowling to a tri-motor commercial transport having two of its engines suspended in a strut arrangement below each wing. They were puzzled when tests in the propeller tunnel did not show the expected drag reduction. They tried placing the engines in various locations above and below the wings and also mounted in line with, and faired into, the leading edge of the wing. Drag reduction in the latter position was again dramatic, and led to the leading edge engine locations of the Douglas DC-1, Lockheed Electra, and Boeing Model 247 airliners. [2 pp.12-13]

By 1931, NACA’s flight testing of instrumented airplanes was also becoming highly sophisticated. In this year, Langley’s in-flight investigation of airplane pilot handling qualities was made public in NACA Technical Report 369: “Maneuverability Investigation of the F6C-3 Airplane with Special Flight Instruments.” This would be the first ever report in the new field of airplane handling qualities, and many more would follow.

The propeller research tunnel was very useful, but its 20-foot diameter meant that it could not accommodate complete full sized aircraft, only smaller model airplanes. In 1929 Congress authorized a much larger ‘full scale” wind tunnel. Its test area would be 60 feet wide by 30 feet high, and would be first used in May 1931. It would be the largest wind tunnel in the world until 1945. By 1958, Langley would have a dozen wind tunnels with various specialties. One of the specialties was studies of airplane icing and in-flight ice removal which brought about a refrigerated wind tunnel in 1928. The need to determine and publish the detailed lift and drag characteristics of a large number of airfoil shapes resulted in Langley’s two dimensional low turbulence tunnel dedicated to airfoil testing. This led to a 1933 landmark NACA publication on the “Characteristics of 78 Related Airfoil Sections” [2, pp.13-15] [52, p.19]

A Vought O3U-1 “Corsair,” was the first airplane tested in the Langley Lab full scale 30-foot by 60-foot tunnel. NACA photo

The Ames Laboratory

By 1936 various NACA Committee members, as well as other U.S. aeronautics experts had visited the growing number of aeronautical research facilities in England and Europe, and voiced a growing concern that America was soon going to be eclipsed in such research. Furthermore potential new workload was going to overwhelm Langley facilities and personnel. There was growing pressure to either enhance the Langley Laboratory or establish one or more new NACA Laboratories. There was also the realization that not only expansion space at Langley was limited, but also it was probably not wise to concentrate all the nation’s aeronautical research facilities at one location. A proposal for additional laboratories to President Roosevelt and Congress in 1938 was looked on favorably by the President but turned down by Congress.

In 1939, however, under intense lobbying by the military services, concerned scientists, and the media, Congress approved a new lab. Location considerations included: accessibility by the growing number of airplane manufacturers on the west coast, good flying weather, location on an existing military site, adequate electrical power supply for wind tunnels, and space of at least 100 acres. The Advisory Committee reviewed 34 possible locations and reported back to Congress in September 1939 that it had chosen a site at Moffet Naval Air Station near Sunnyvale, California. Construction was to begin in early 1940 and a contingent of engineers was to be dispatched from langley to supervise construction. They, in fact, started work on wind tunnel blueprints and facilities architecture even before leaving, and one of their designs was a new wind tunnel eclipsing the 30 X 60-foot Langley full scale tunnel. It was to have a 40 by 80-foot test section, and would not be completed until 1944. Three of the smaller tunnels would be in operation by the end of 1941. The new laboratory was to be named after Dr. Joseph S. Ames who had been NACA chairman from 1927 to 1939. [52, pp.32-33] [2, pp.22-23]

The Ames Laboratory high speed 16-foot wind tunnel. Its air speed could be brought up to the transonic range, and it became operational only a few days before the Pearl harbor attack. Its capabilities were used to enhance the design of a number of WW II Allied fighter aircraft. NACA photo A-12679

Initial planning for Ames Laboratory facilities included an engine research lab dedicated mainly to research on aircraft engines and propellers. Further review of the required facilities and capabilities pointed to a large laboratory that, for strategic survival purpose, might best be a new, separate NACA lab. The final result was Congressional authorization to establish a new Aircraft Engine Research Laboratory at Cleveland, Ohio. The lab’s research would range from the chemistry and physics of fuel combustion to flight testing new engines in specially instrumented aircraft. The initial cadre of propulsion engineers and technicians was to come from the Langley Lab. By the outbreak of World War II, the National Advisory Committee for Aeronautics easily held the title as premier aeronautical research institution of the world. [52, p.33] [2, p.23]

As a tribute to NACA’s contributions to the WW II effort, in 1943 Secretary of the Navy, Frank Knox wrote:

The Navy’s famous fighters - the Corsair, Wildcat, Hellcat - are possible only because they are based on fundamentals developed by the NACA. All of them use NACA wing sections, NACA cooling methods, NACA high lift devices. The great sea victories that have broken Japan's expanding grip in the Pacific would not have been possible without the contributions of the NACA. [2, p.24]