Proppants

The original version of this article was created by Francesco Gerali, 2020 Elizabeth & Emerson Pugh Scholar in Residence at the IEEE History Center

It is recommended this article be cited as:

F. Gerali (2020). Proppants, Engineering and Technology History Wiki. [Online] Available: https://ethw.org/Proppants

Introduction

Hydraulic fracturing is the process of injecting fluids into oil or gas bearing formations at high rates and pressures to generate fractures in the rocks (Fig. 1). The task of proppants, or propping agents, is to provide and maintain long term efficient conduit for production from the reservoir to the wellbore. Proppants are mixed with the fracturing fluids and injected downhole into the formation (Fig. 2).

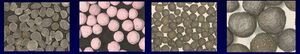

Today, proppant materials can be grouped into three main categories: rounded silica sand, resin coated sands, sintered or fused synthetic ceramic materials (Fig. 3). The most common used base materials are sand, ceramic, and sintered bauxite. Calculations about the proppants performance into the formation injected also improve to the well stimulation operation; to quantify proppant performance, specific quality-control procedures have been elaborated in past 30 years by the American Petroleum Institute[1] (API) and the International Standards Organization (ISO). Proppant selection, which includes the proppant type, size and shape, is a very critical element in stimulation design. Proppants have to withstand high temperatures, pressures, and the corrosive environment present in the formation. If the proppant fails to withstand the closure stresses of the formation, it disintegrates, producing fines or fragments which reduce the permeability of the propped fracture.

Availability and cost are the most desirable attributes of proppants, but also physical qualities of both natural (e.g. sand grains) and man-made, or artificially engineered, (such as resin-coated sand and ceramic) proppants are crucial. The structural properties of proppants, both natural and manmade are gauged following specific criteria:

- Conductivity: the amount of flow that the proppant will allow.

- Acid Solubility: tests of solubility in acid can indicate contaminants and determine how the proppant is likely to perform underground.

- Shape: the degree to which a proppant grain is round or spherical determines how it will react to fracking fluids and produce oil or gas.

- Crush resistance: proppant grain ability to withstand the stress of high bottom-hole pressures.

- Solubility: the inability for the proppant to dissolve within a substance.

- Turbidity: the absence of impurities such as clay, silt, etc. within the proppant material.

History and recent advancements in proppant technologies (1947-2018)

The first experimental use of hydraulic fracturing took place in 1947 with the use of about 20,000 pounds (9.1 metric tons) of river sand. The fracturing treatments followed used construction sand sieved through a window screen. There have been a number of trends in sand size - from very large to small - but since the beginning a –20/+40 US-standard-mesh[2] sand has been the most popular. Currently, approximately of the 85% of the sand used match this size.

Since then, the process of stimulating and fracturing wells has continually evolved as have the materials and technologies employed to do likewise. In addition to naturally occurring sand grains and walnut hulls, in past 70 years, especially after the 1980s Texas boom, several proppant materials were carefully sorted for size, shape, weight (e.g. ultra-lightweight) and mechanical characteristics (e.g. multifunctional). Numerous propping agents have been evaluated throughout the 1960s and the 1970s, including resin-coated sands, plastic pellets, rounded, Indian glass beads, ashes and steel shot (Fig. 4). Since the 1980s were developed and commercialized aluminum pellets, high strength glass beads, sintered bauxite, and fused zirconium.

Experimentation and new fracking techniques led to great steps forward in proppant studies, peaking in innovative breakthroughs achieved in the 2010s. The manmade proppants provided unique capabilities that natural proppants could not: scientists and manufacturers have developed proppants that can be engineered to mitigate or withstand many of the physical and environmental conditions existing in deep in fractured zones. The new age of proppants - still in combination with traditional proppants - allowed resource developers to match up with conditions and characteristics of their target rock formations with more effectiveness. By adjusting proppant properties such as size, geometry, and weight, the optimal channel for unconventional hydrocarbons production flows can be obtained in different kinds of rocks.

Sand Proppants

Sands have remained, for decades, the most used proppant agent for hydraulic fracturing, mainly due to their low cost and easiness to handle. Fracking sands are extracted from silica sand deposits or riverbeds, then crushed, washed, dried and (but not always) sized. These are mechanical processes and no special (expensive) chemical action is needed. Two types of sand proppants are chiefly in use since the beginning of the practice: white quartz sand (light colored because the few impurities), and brandy brown quartz sand (first experimented in 1958) with low percentage of silica and high impurity content, which makes it more prone to crushing at lower stress.

The rate of concentration of sands in the drilling fluids (lbm/fluid gal)[3] remained low until the mid-1960s, when viscous fluids such as crosslinked water-based gel and viscous refined petroleum were introduced. Large-size propping agents were advocated then. The trend then changed from the monolayer or partial monolayer concept to pumping higher sand concentrations. Since that time, the concentration has increased almost continuously, with a sharp increase in recent years. These high sand concentrations are due largely to advances (pression and velocity) in pumping equipment and improved fracturing fluids. For example, today it is not uncommon to use proppant concentrations averaging 5 to 8 lbm/gal throughout the treatment, with a low concentration at the start of the job, increased to 20 lbm/gal toward the end of the job.

Lightweight proppants

The specific gravity[4] (s.g.) of sands has an average value of 2.65; the manufactured ceramic proppants have s.g. around 3.9. Both are heavier than the water (s.g. of 1.0) or brine solutions (s.g. of about 1.2) which are typical base fluids used to carry the proppant to the formation. There are three major trade-offs in using lightweight proppant with high density proppants:

- smaller fracture volume for a fixed weight of proppants

- higher costs

- faster settling rate in the carrier fluids.

To prevent the settling factor are used high viscosity fracturing fluids to keep the proppant material suspended in order to allow it to penetrate more deeply into the fractures. Ultra-lightweight proppant is preferred in some applications since it reduces proppant settling, requires low fluid viscosity to transport and allows for increased propped length. They can also be more useful in situations where high pump rates or carrier fluids with low viscosities are needed. Several techniques have been used to reduce specific gravity of the proppant. The S.G for lightweight proppant ranges from 0.8 to 2.59.

To make lightweight proppant were selected proppant material which has a lower specific gravity. Walnut shells, pits and husks were the earlier types of lightweight proppant used in the field. Even though such materials would penetrate deeper into the formation, their low structural strength limits their applicability to formations with relatively low closure pressures. Additionally, small particle fragments resulting from crushing of such materials reduce the conductive space available for fluid flow by reducing the fracture network.

Resin coated proppants

Since fracking sand is easily friable and creates fines when it is over-stressed, resin coated sand was developed to enhance the conductivity of sand. Resin-coated sands (RCS’s) have been a mainstay of stimulation treatments for more than 40 years. The longevity of RCS’s is primarily due to its ability to form a pack within fractures thus preventing proppants from flowing back into the wellbore during fracking and production. It’s also stronger than sand and often the choice when compressive strength is needed to prevent crushing in areas of extreme pressure at depth. The main disadvantage of the resin coating is that since the coating material is made of polymers, they tend to have low softening temperatures or low degradation temperatures compared to inorganic materials.

Coating technologies have been applied later to glass beads and ceramic proppants as well. All these proppants belong to resin coated proppant (RCP) category and can also be used as a way to prevent sand production in areas of soft formations where sand control is needed.

Proppants are either pre-coated with resin in a production facility and taken to location (precured) or coated (curable) at the well site by liquid resin coating systems (LRC). The performance of the proppant depends on the properties of the cured resin material. The most commonly used resins used to coat proppants are epoxy resins,[5] furan,[6] polyesters, vinyl esters, and polyurethane. Epoxy resin is the main one used for proppant coating, mainly because it has very good mechanical strength, heat resistance and chemical resistance. Furan has great resistance to heat and water, but it does not provide high mechanical strength. Polyurethane provides also great mechanical strength, good heat resistance and chemical resistance, but just when the application temperature is below 250 F.

The chemical crosslinks that form during the cure of the resin materials do not allow the cured material to melt or flow when re-heated. However, cured/crosslinked resins do undergo a very slight softening at elevated temperatures at a point known as the Glass Transition Temperature[7] (Tg). When the temperature is above the Tg, the mobility of the polymer chains increases significantly and the cured resin changes from a rigid/glassy state to more of a rubbery/compliant state. In this case, the resin system becomes soft and the strength decreases. So Tg has been used as a valuable parameter to determine performance limit of resins.

Ceramic Proppants

Sands showed to be not capable to withstand high closure stresses (up to 6000 psi). That gap got solved with the development of higher strength ceramic proppants manufactured since the early 1980s from sintered bauxite, kaolin, magnesium silicate, or blends of bauxite and kaolin. Compared to sands, the synthetic ceramic proppants have higher strength and is more crush resistant especially where closure stresses exceed 8000 to 10,000 psi. They are more uniform in size and shape and has higher sphericity and roundness to yield higher porosity and permeability of the proppant bed. Furthermore, ceramic proppants have a remarkable chemical and thermal stability, which is functional to reduce the diagenesis effect. Ceramic proppants were since the beginning an engineered product featured by a more complex manufacturing. Since 1984, lightweight ceramics (LWC) were developed. Few year later followed the intermediate density ceramics (IDC) and high density ceramics (HDC) (Fig. 5).

The alumina content of ceramic proppants correlates well with the pellet strength and the proppant density. The approximate correlation between alumina content and strength is true provided the proppant grains are of high quality and manufactured in a manner which minimizes internal porosity. LWC typically contains 45e50% alumina; IDC contains 70e75% alumina; HDC contains 80e85% alumina. However, in 2014 it was first coupled a raw material that is very high in alumina content with a new manufacturing process that creates extremely spherical, mono-sized, fully densified particles. Such proppants are referred to as ultra-high-strength proppant (UHSP) can be rated up to 20,000 psi in crushing strength.

Multifunctional proppants

Multifunctional proppants may be used to detect hydraulic fracture geometry or as matrices to slowly release downhole chemical additives, besides their basic function of maintaining conductive fracture during well production. Multifunctional proppants such as traceable proppants and contaminant removal proppants (filled or costed with chemical additives) have been used to prolong the well performance.

Traceable proppants answered to the need of obtaining detailed information about the stimulation treatment, such as location and geometry of created hydraulic fractures. It is also important to determine if the hydraulic fracture has extended to unwanted zones such as water zones. Nuclear logs are one of the common ways used to trace the extent of the induced fracture detection and it involves the use of radioactive materials (tracers) that can be detected by gamma ray logging tools. The radioactive tracers can be made by coating sand with radioactive materials, mixing with pulverized natural radioactive materials, impregnating radioactive ion exchange resins or ground plastic into proppants. When mixed with regular proppant during the fracturing process, these radioactive materials will emit gamma rays. Then gamma ray detectors, which have been in use in the oil & gas industry since early 1940's, are used to log after the hydraulic fracturing process. The gamma rays from the radioactive tracers are detected, recorded, and analyzed either in real time during wireline logging run, or recorded into memory and processed later after the tracers are retrieved. This technique is typically very effective and can be used to trace signals from multiple tracers.

Hexion Inc.[8] in 2010 has patented (applied in 2006) an advanced technique which involves non-activated radiation-susceptible materials capable of being activated by a neutron source. These materials can be incorporated into the resin coating of the proppant or into the composite composition of the proppants to be pumped downhole the same way as the radioactive tracers. Then a logging tool which contains a pulsed or continuous neutron source and gamma ray detector is moved past the intervals containing the traceable proppant. The gamma rays emitted from the neutron activated tracers are then detected by the sensor in the tool when it passes through a zone containing the activated material. The advantage of this technique is that it resolves the concerns of the handling, transportation, storage, and environmental concerns of handling a radioactive material.

In 2011 it was reported a technique which can detect the fracture geometry without using radioactive elements. This is accomplished by incorporating a high thermal neutron capture compound (HTNCC) at low concentrations into each ceramic proppant grain during manufacturing process. The HTNCC-containing proppant can be pumped downhole and into the induced fractures. Because these high thermal neutron capture compounds absorb neutrons, changes to neutron levels can be detected using conventional compensated neutron logs (CNL) or pulsed neutron capture (PNC) tools. The proppant containing zone is scanned using after-frac compensated neutron logs and the results are compared with the corresponding before-frac logs. The location of the detectable proppants was determined from analysis of before-frac and after-frac compensated neutron logs. This technological advancement will most probably expand the portfolio of tracers, at the same time diminishing the downsides of using radioactive agents.

The concept of using proppant grains to filter, clean, or remove possible contaminants from a production well have also been developed in early 2010s: those were called contaminant removal proppants. Depending on the nature of the contaminants, they can be removed by any chemical, physical, or biological ways. This can be achieved by incorporating chemical contaminant removal component either coated onto the proppant grains or filled in the pores of porous proppants (Fig. 6).

Non-spherical proppants

Traditionally, the ideal proppant shape has been conceived spherical or nearly spherical and non-angular: spherical proppants with narrow size distribution provide fractures with the highest conductivity. A lower Krumbein[9] number indicates a more angular proppant (Fig. 7). Angular and pointed proppant particles tend to break off points, which lead to lower conductivity at higher closure stress. Ceramic proppant and resin-coated ceramic proppants require an average sphericity of 0.7 or greater and an average roundness of 0.7 or greater. All other proppants shall have an average sphericity of 0.6 or greater and an average roundness of 0.6 or greater.

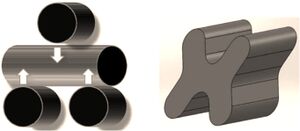

Between 2010 and 2013, different shapes of proppants - elongated and rod-shaped - other than conventional spherical shape have been produced (Fig. 8). They present higher conductivity factor due to the higher porosity in the packing. A series of laboratory observation held in late 2000s noted the untapped pack porosity both for spherical and rod-shaped proppants. The conductivity results, 37% spherical vs. 48% rod-shaped demonstrated the benefit of the latter. The variation in rod length and diameter can increase the risks of placement, impact conductivity and affect proppant flowback performance.

In 2015 was investigated a different shaped high-drag ceramic proppant based on the relationship that increasing the drag force of the proppant particles will reduce the proppant settling velocity. It was designed and optimized in a way that center of gravity and centroid of volume do not align in a stable manner, so the proppant particles tumble and flutter when settling in a fluid: this design results into a slower settling time compared to conventional spherical sand proppant.

Conclusions

Developing unconventional petroleum and gas plays is very cost-sensitive, especially when using proppants with advanced characteristics. With the development of deeper reservoirs and more complex fracture geometry and formation properties, the performance requirements for proppants have become very demanding (Fig. 9).

See also

References

Acharya, A R. Tue . "Viscoelasticity of crosslinked fracturing fluids and proppant transport". SPE (Society of Petroleum Engineers) Product. Eng.; (United States). Journal Volume: 3:4

Alkhasov, Solomon. 2014. Commercializing A Resin-Coated Proppant. Case Western Reserve University. Master of Science Thesis.

Campos, V. P. P. de, Sansone, E. C., & Silva, G. F. B. L. e. 2018. “Hydraulic fracturing proppants”. Cerâmica, 64 (370), 219-229.

Gallagher, David. 2011. “Hierarchy of Oily Conductivity”. Journal of Petroleum Technology 63 (4): 18-20.

Liang, Feng, Sayed, Mohammed, Al-Muntasheri, Ghaithan A., Frank F., Chang, Li, Leiming 2016. “A comprehensive review on proppant technologies”. Petroleum 2: 26-39

Gallegos, Tanya J., Varela Brian A. 2015. Trends in Hydraulic Fracturing Distributions and Treatment Fluids, Additives, Proppants, and Water Volumes Applied to Wells Drilled in the United States from 1947 through 2010—Data Analysis and Comparison to the Literature. Scientific Investigations Report 2014–5131. Reston, Virginia: U.S. Geological Survey.

Gidley, John L., Society of Petroleum Engineers. 1989. Recent Advances in Hydraulic Fracturing. 12th ed. Richardson, TX: Society of Petroleum Engineers.

Gurley, D G, Copeland, C T. 1974. Method for forming a consolidated gravel pack in a subterranean formation. United States Patent Number: US 3854533. Assignee: Dow Chemical Co.

Halliburton Services. 1971. The FracbookTM Design/Data Manual for Hydraulic Fracturing. Duncan, OK: Halliburton.

Jacobs, James A., and Stephen M. Testa. 2019. Development of Unconventional Oil and Gas Resources: Horizontal Drilling and Hydraulic Fracture Stimulation Techniques. Newark: John Wiley & Sons, Incorporated.

R.R. McDaniel, S.M. McCarthy, M. Smith. 2010. Methods and Compositions for Determination of Fracture Geometry in Subterranean Formations. U.S. Patent No. 7,726,397 B2.

Olsen, T.N., Bratton, T.R., Thiercelin, M.J.: “Quantifying Proppant Transport for Complex Fractures in Unconventional Formations,” Paper SPE 119300, presented at the 2009 SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, 19-21 January.

Page, J.C., Miskimins, J.L.: “A Comparison of Hydraulic and Propellant Fracture Propagation in Shale Gas Reservoir,” 09-05-26, J. Can. Pet. Tech., Vol 48, No. 5, May 2009.

Zendehboudi, Sohrab and Bahadori, Alireza (eds). 2017. “Exploration and Drilling in Shale Gas and Oil Reserves”. Shale Oil and Gas Handbook. Gulf Professional Publishing: 81-121.

Further Reading

- ↑ https://www.api.org/products-and-services/standards/standards-plan

- ↑ https://www.dualmfg.com/Pdf/USA-Standard-Mesh-Chart.pdf

- ↑ https://www.glossary.oilfield.slb.com/en/terms/l/lbmbbl

- ↑ https://www.caee.utexas.edu/prof/kinnas/319lab/Book/CH1/PROPS/specgrav.html

- ↑ https://pslc.ws/macrog/epoxy.htm

- ↑ https://polymerdatabase.com/Polymer%20Brands/Furan%20Resins.html

- ↑ https://www.netzsch-thermal-analysis.com/en/contract-testing/glossary/glass-transition-temperature/

- ↑ https://www.hexion.com/en-US/

- ↑ https://apps.dtic.mil/dtic/tr/fulltext/u2/a080983.pdf