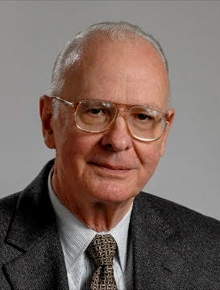

Oral-History:Douglas W. Fuerstenau

About Douglas W. Fuerstenau

Douglas W. Fuerstenau is P. Malozemoff Professor Emeritus of Mineral Engineering in the Dept. of Materials Science and Engineering, University of California, Berkeley. His career of nearly seven decades started at the South Dakota School of Mines and Technology, where he received his B.S. in Metallurgical Engineering in 1949, followed by an M.S. from the Montana School of Mines in 1950, and his Sc.D. degree under Professor A. M. Gaudin at M.I.T. in 1953. His professional career began as an assistant professor in the Dept. of Metallurgy at M.I.T., followed by industrial experience as section leader in the Metals Research Laboratory of Union Carbide and manager of mineral engineering for Kaiser Aluminum and Chemical Company. In 1959, Dr. Fuerstenau joined the faculty of the University of California, to teach courses and conduct research on mineral processing and the surface properties of materials. During the course of his career, he supervised the research of 60 graduate students for their Ph.D. degrees and 65 for their M.S. degrees in the broad field of processing minerals and particulate materials. Through his inspiration, numerous students have achieved notable distinction in careers in academia, industry and government worldwide.

Elected to the National Academy of Engineering in 1976, Dr. Fuerstenau is widely recognized for his seminal contributions to mineral processing and extractive metallurgy, and his research results are widely used and referenced extensively. He has served in numerous advisory and leadership roles in technical organizations and societies, advisory boards to universities, international editorial boards, Government committees regarding mineral resources, and has contributed widely at the international level to resource programs. For 22 years he was a director of Homestake Mining Company.

An Honorary AIME Member, Dr. Fuerstenau has received numerous awards from AIME and its constituent societies, starting the with the Hardy Gold Medal. His extensive international recognition includes such awards as the Senior American Scientist Award from the Alexander von Humboldt Society in Germany and the Lifetime Achievement Award from the International Mineral Processing Congresses, honorary doctorates from Belgium and Sweden, and election to foreign engineering academies in Australia, India, and Russia.

Further Reading

Access additional oral histories from members and award recipients of the AIME Member Societies here: AIME Oral Histories

About the Interview

Douglas W. Fuerstenau: An Interview conducted by Eleanor Swent in 2001, Regional Oral History Office, The Bancroft Library, University of California, Berkeley, 2011.

Copyright Statement

All uses of this manuscript are covered by a legal agreement between The Regents of the University of California and Douglas Fuerstenau, dated July 23, 2001. The manuscript is thereby made available for research purposes. All literary rights in the manuscript, including the right to publish, are reserved to The Bancroft Library of the University of California, Berkeley. No part of the manuscript may be quoted for publication without the written permission of the Director of The Bancroft Library of the University of California, Berkeley.

Requests for permission to quote for publication should be addressed to the Regional Oral History Office, The Bancroft Library, Mail Code 6000, University of California, Berkeley, 94720-6000, and should include identification of the specific passages to be quoted, anticipated use of the passages, and identification of the user.

It is recommended that this oral history be cited as follows:

Douglas W. Fuerstenau, “Mineral Processing Engineer and Scientist: In Education, Research, Industry, and International Cooperation” an oral history conducted by Eleanor Swent in 2001, Regional Oral History Office, The Bancroft Library, University of California, Berkeley, 2011.

Interview

INTERVIEWEE: Douglas W. Fuerstenau

INTERVIEWER: Eleanor Swent

DATE: 2001

PLACE: Berkeley, California

EARLY YEARS GROWING UP IN SOUTH DAKOTA, 1928 TO 1945

[Interview 1: July 23, 2001 in his office at 477 Evans Hall, UC Berkeley]

Parents, Grandparents, and Early Years on South Dakota Farms

Swent:

The first thing is for you to tell us when and where you were born.

Fuerstenau:

I was born December 6, 1928, in Hazel, South Dakota, in a farm area. Hazel is a little town in Hamlin County, South Dakota, about twenty miles southwest of Watertown, South Dakota, Watertown being one of the bigger cities of the state.

Swent:

Was it flat prairie country?

Fuerstenau:

It was east of the very flat farmland in the central part of the state that once was the ancient Lake Agassiz. It is actually very good farmland in the eastern part of the state that is not totally flat and has lots of sloughs and lakes which are remnants of the ice age. My ancestors homesteaded there. My grandfather on my father’s side was born in Germany about 1860, and came from Posen, which is east of Berlin. He came to Minnesota after a brother had earlier come to the States. I guess he went back and convinced his other brother to come also. Then on returning from Germany, from what I read, in 1882 my grandfather homesteaded in what was then Dakota Territory.

Swent:

What was his name?

Fuerstenau:

Emil. Emil Fuerstenau. I think maybe his middle name was Adolph and I’m sure glad that I was not named after my grandfather. But the grandson of our very good friends, the Schoenerts, in Germany, who is only a few months old, has the name Emil. So Emil is apparently still a good German name.

My grandmother also came from Posen and she was born in 1872; I remember that from childhood. I think she came to this country when she was sixteen, and lived a couple of years in Chicago with an aunt, then married my grandfather and moved to the farm. They had six sons, of which my father, who was born is 1897, was the second oldest. That grandfather died of stomach cancer at age 55, and one of my dad’s uncles also died of stomach cancer at that same age. Must have had too much Schwarzwalder schinken or something.

Swent:

What was your father’s name?

Fuerstenau:

Erwin Arnold Fuerstenau. All of my uncles have good German names: Adolph, Martin, Walter, Elmer, Herbert. My father said he couldn’t speak English until he went to school; they were raised on German.

Swent:

Was there a German community there?

Fuerstenau:

Oh yes. Nearly all of the farmers in the immediate vicinity were German.

Swent:

It wasn’t just the one family?

Fuerstenau:

I know of three somewhat interrelated families. All of them moved from around Posen to that area near Watertown. My grandmother’s maiden name was Stoltz, and there were a lot of Stoltzes who also lived in that general area. A third family that I guess had married some Fuerstenaus was named Krenz, and those three families owned a lot of farms in an area of several square miles. Obviously all homesteaded at about the same time.

Swent:

Had they been farmers in Germany?

Fuerstenau:

No, no. From what I heard from my father, his grandfather was a professional musician in Posen. It is said that he was born in 1825 and had a stipend from the state until 1870. That’s when Bismarck came in and must have cut out such subsidies, the way I read it. Probably the thing for younger members of the families to do was to come to this country as homesteaders. So on that half of the family, I’m obviously pure German.

The other half, on my mother’s side, is Scandinavian. Her mother, my grandmother, was born in Iowa in 1874. Her name was Dagmar Almblom. Danish. She came as a little girl to what was then Dakota Territory also. That grandmother went through the tenth grade, and for a woman in the 1880s in Dakota Territory to go through tenth grade in school was obviously a rare thing.

Swent:

That was very well educated.

Fuerstenau:

Oh yes. She was a very bright woman. The grandfather on that side, who I never met, came from Norway. So my mix is half German, half Scandinavian. They all homesteaded in an area near Hayti, which is a small town south of Watertown. This is a localized area where numerous Norwegians, Swedes and Finns settled at that same time. My mother’s father had emigrated from Norway. Interestingly, there was virtually no intermixing between the German and Scandinavian farming areas.

My mother was born in 1901. Her name was Hazel Pauline Karterud. Typical Norwegian spelling of her last name. My mother graduated from high school and then apparently went a year or so to normal school in Madison to teach school. Her first job, at about age nineteen, I think, was a school teacher in the farm area, at the school district where my dad was living. She taught in a one-room country school house, grades one to eight. I’ve seen this little old school house. It was still there in a field a few years ago. A cousin of my father’s, an older cousin, was chairman of the school board, and I remember my mother telling me that he said that the school teacher can’t be dating a Fuerstenau when a Fuerstenau is head of the school board, and so they didn’t renew her contract and I’m glad of that because this was about 1920 or ‘21. About a year or two later my dad started making contact again with my mother, and after a couple years, they got married, in 1925. I’m certainly glad that they didn’t get married in 1921. [Laughter]

Swent:

She couldn’t continue teaching then?

Fuerstenau:

After that she moved to Herried, South Dakota, in the northern part of the state where her oldest married sister lived. My mother taught there a couple of years.

Swent:

There was a famous blizzard in—wasn’t it 1889?

Fuerstenau:

Eighty-eight.

Swent:

Eighty-eight. Did your family have recollections of this?

Fuerstenau:

My Grandmother Karterud wrote down her remembrances of that. She said that that January morning was very mild so some people had gone to town and others had taken animals out to water. At about eleven in the morning, the blizzard arrived abruptly with blinding snow and the temperature dropped abruptly. Many animals and a number of people froze to death, or later died of pneumonia brought on by their exposure. Also, I have a coffee grinder that my grandmother had had, a little old coffee grinder that you see in antique shops. And there’s a little note in there stating that this coffee grinder was shared by three, four families during the blizzard of ‘88 in which they roasted wheat to make it taste like coffee, and ground it. One of the family members was named Mellette, who later became the first governor of South Dakota. He had a farm near by, around Watertown. Yes, the blizzard of ‘88 was, is very infamous.

Swent:

It was a terrible, terrible time.

Fuerstenau:

And came on unexpectedly. Well, they had no way of predicting it in those days.

Swent:

It must have been awfully hard homesteading.

Fuerstenau:

Yes. They generally started with sod houses, and then a small house. My Grandmother Karterud said that the worst problem was getting fuel to burn for cooking and heating because there were no trees for miles around. Their fuel consisted of fried cow pies, straw and hay. They were plagued with dry years when there was little rain and no snow. The shallow lakes dried up. The farm that my Fuerstenau grandparents had when my dad was raised had many large buildings and were all well kept—and a large house. It was probably built, my guess, is 1910-ish, or maybe even a little later. Since my grandfather had homesteaded there about 1880, his land must have been quite fruitful. There was a large cow barn and horse barn, a big granary and chicken coop.

I have a very good remembrance of when I was very young and, probably 1932 or 1933, a tornado came through. I remember going over to my grandmother’s farm, fairly near by, just five miles away maybe. And this tornado absolutely smashed the windmill down, and the silo, which was adjacent to the cow barn. We’re talking big buildings. The horse barn was absolutely smashed flat, and the granary flat, which showed you how narrow a tornado can cut through. It missed the house, missed the cow barn. And you know, every farm there had what I remember were storm cellars. Not part of the house, but out where you could go down in if a storm was coming. And obviously they were used primarily for storing vegetables and things for winter—cabbage, potatoes, et cetera.

Swent:

And they called it a tornado?

Fuerstenau:

Oh, it was a real tornado.

Swent:

Not a cyclone?

Fuerstenau:

No, it was a tornado.

Swent:

My recollection is that in Iowa they called it a cyclone. They’re the same, but I think it’s just a matter of terminology.

Fuerstenau:

Cyclones can be huge, or fast moving, slow moving. It’s circular wind, of course.

Swent:

Yes. They grew wheat?

Fuerstenau:

Wheat, corn, rye, oats—until the dust storms came. After that, my mother said that one year all they got was Russian thistles. And she said that another year they had a pretty good crop of rye but it sold for only five cents a bushel.

I can remember these dust storms coming. One in particular that I remember, you could see on the horizon an orange-brown layer building up as this storm came closer. Whenever that happened my mother would wet sheets and put the sheets on the inside of the windows to collect the dust so it wouldn’t get throughout the house. And I remember one particular storm when the wind really blew hard—it probably was 1932. My dad must have been somewhere else because my mother took us out from the house under a blanket. I don’t know why. I would have stayed in the house, but she took us outside the house and under a blanket. She, and my sister, and myself, and my one brother who was probably one or two years old. So we were out under a blanket until this dust storm blew by. And I can remember playing along the road, you know, where the dry dust collected along the fences in drifts. Along the fences, it looked just like snow drifts in South Dakota, only this was just fine dirt. So that’s just what eastern South Dakota was like in the early 1930s. Now staying in the Black Hills, you didn’t see any of that, did you?

Swent:

Not in the Hills, no.

Fuerstenau:

Would the sky ever be sort of—?

Swent:

I don’t recall seeing that at all.

Fuerstenau:

That’s because there would have been little farming in that part of the state. As you know, the dust bowl era started because they plowed Montana in World War I to grow wheat. That’s what really was the later cause of the dust storms.

Swent:

I don’t remember the dust storms in the Hills. I remember forest fires in those dry years.

Fuerstenau:

There it would have been bad.

Swent:

But we drove across the state to visit my grandmother in Iowa, so I saw it driving across the state. And grasshoppers, too.

Fuerstenau:

I’ll tell you about grasshoppers later. But those dust storms were really, really bad. It just looked exactly like the pictures one sees of the dust bowl era.

Swent:

You mentioned the windmill. This was for water. You had a well?

Fuerstenau:

A well, yes. All water was well water. And I have two brothers. My brother Dick, who was born in 1931, caused a real scare climbing up the windmill before a storm.

Swent:

Let’s get their names.

Fuerstenau:

My sister, Jean is a year older than I am. She was born in ‘27, I in ‘28, my brother, Dick, 1931, and Maurie, whom you know, in 1933. As a matter of fact, I can still remember the very day that Maurie was born. I was only four and a half. He was born in June; my birthday is December. But I still remember the very day.

Swent:

Was he born at home?

Fuerstenau:

My grandmother’s house. I remember an uncle taking my sister and me to the park in Watertown, where my Grandmother Karterud lived. And we came back; there was Maurie. [laughs]

[Added by Douglas Fuerstenau during editing: My sister, whose full name is Shirley Jean, is Mrs. James Hadeen and currently lives in Laramie, Wyoming. My brother Dick, whose full name was Richard Kendall, had a 20-year career as a petroleum geophysicist with Mobil Oil Corporation in Texas. Tragically, he died at the age of 43 from lung cancer, leaving two young daughters, Julie and Kendall. My youngest brother, Maurice Clark, has had a long career in metallurgical education and currently is distinguished professor of metallurgical engineering at the University of Nevada in Reno.]

Anyway, when my brother Dick was only about two and a half, he climbed up the steps to the top of the windmill. And a storm was coming, and that was a great traumatic thing, you know, to get this little kid down without scaring him. You know that windmills have a ladder that goes clear to the top, and Dick was quite a way up it. I don’t recall how they got him down with the storm coming. Whether my dad went up, gently to not scare the little kid, or whether they coaxed him down. But the event is still part of my many early memories of the farm.

But you talked about water, and of course on a farm the drinking water is in a pail with a dipper. Perhaps when I was about three, or a little more, one day in the summer my grandmother came out from Watertown, and she and my mother were cleaning something with white gasoline. And they put the white gasoline in the dipper, the drinking dipper, and I came in and took a drink of this thing. And I am lucky, I suppose, to be alive. I can still remember the horrendous shock of taking a big gulp of white gasoline. They must have gotten me to throw it right up. An awful dumb thing to do, using the dipper that way. Like I say, I still remember it, the shock of it.

Swent:

You’re lucky that you didn’t get killed by that.

Fuerstenau:

Oh yes, you’re right.

Swent:

There was no irrigation, of course?

Fuerstenau:

No. In fact, I have seen some old pictures that my dad had. All the farmers tried to do the reverse, apparently, I would say around 1915. Eastern South Dakota has a lot of sloughs, as you know, because it was all glaciated. And they made an effort to drain the small sloughs by digging a rather big ditch that went for quite a distance. So of course, what they did is they lowered the water table, right? Each farm—as you’ve probably seen driving across the eastern part of South Dakota—may have several depressions that would have water in them in the spring and be dry later on in the summer. But you couldn’t farm those areas, so they actually tried to do the reverse. I’ve never seen those ditches, which meant that they obviously discovered what they had done. By lowering the water table, they had hurt the rest of the land. So there was no irrigation there.

Swent:

Did you have electricity?

Fuerstenau:

No. Kerosene lanterns and lamps with gas mantles which actually gave out a fairly bright light. Well, that went on until about 1940 or so, I think, in eastern South Dakota. Until the REA [Rural Electrification Act of 1936] came in. there was no electricity. A few farmers would—very few—have a windmill wind charger that would charge batteries to provide electricity for the house or barn. It was that sort of thing. Even churches had just kerosene lamps if there was an evening service.

Swent:

Did you have plumbing in the house?

Fuerstenau:

No, outdoor toilet. That must have been cold in the winter, that’s all I can say. [laughter] By the way, there is a classic little book by [Charles] Chic Sale titled, The Specialist, which humorously describes the design and construction of outhouses. Chic Sale came from South Dakota. However, my grandmother’s farm had indoor plumbing, which obviously they must have rigged up with a well system. I’m speaking of the bathroom.

Swent:

They probably had a cistern of some kind.

Fuerstenau:

Oh, there was a cistern. I know that the house had a cistern for collecting rain water, and that cistern water was used for washing because it would have been soft water. Not for drinking, but for washing.

Then, 1934, my parents lost the farm, which I always used to think of how traumatic that was. My mother one time said that they would have been able to hang on, but my father had co-signed a note for a younger brother who wanted to buy a farm. That younger brother couldn’t meet his mortgage payment and both farms were lost. But a few years ago I mentioned to my mother that that probably was the best thing that ever happened at least for me. [chuckles]

Swent:

In a way.

Fuerstenau:

In a way. But to them it was obviously very tragic. And it happened to many people, of course.

Living in Small Towns during Grade School Years, Particularly Lemmon, SD

Fuerstenau:

My dad got some sort of job on leaving the farm, probably through a relative. I don’t know any details. But we moved for a year to Hawarden, Iowa, which is just across the border from South Dakota, down in the southeast corner. It’s north of Sioux City, right on the Sioux River, which comes through Sioux Falls, down to Sioux City where it flows into the Missouri.

So we lived there one year, and I started school there. My sister had started school the year before in the country school. It was about two miles away from the farm where we lived, and I remember walking to school in the fall, few times, and being there all day, and in the spring. If I did that in the fall, I would have only been about four and a half, and that spring I would have been a little over five. But I can still recall some days being there all day at school when my sister was in the first grade.

Swent:

And walking two miles.

Fuerstenau:

And walking that whole way. I have no recollection about winter time, but this was the fall and the spring.

Swent:

Your mom didn’t drive you to school.

Fuerstenau:

I have no idea what happened in the winters; probably it was driving.

Swent:

Did your mother know how to drive?

Fuerstenau:

Oh yes. Anyway, when we went to Hawarden, Iowa, my mother said my dad didn’t seem to know my age and when I started school in the fall I was put in kindergarten and spent that year in kindergarten. So I would have been five. I still have a lot of recollections of that year in school. And then in the summer of 1935, they moved to Lemmon, South Dakota. Have you ever been in Lemmon?

Swent:

Not for a long time, but I have been there.

Fuerstenau:

You know it’s in the northwest part on the state, right on the border of North Dakota. One thing about it—I have a few other things to say about it—there is a petrified wood park occupying about three square blocks. Somebody who locally had a lot of money gathered in petrified wood, either from a ranch he had or something, and built this huge park, making huge conical monuments that might be twenty feet high of petrified wood logs. Lots of them. And he built a castle, things like that, all out of massive petrified wood. It’s kind of an unbelievable thing. I did see that again a few years ago. I remember playing cops and robbers there as a little kid.

We moved there in the summer of 1935 and that fall, when I started school, I was put in the second grade so I skipped the first. Lemmon was then a town of about 1500 people; I think maybe it’s double that now. About fifteen miles south was Grand River, one of the South Dakota rivers. I remember as a little kid, once in a while with family, going down there fishing and so on. But this town of Lemmon—

Swent:

You lived in town?

Fuerstenau:

Right in town, in about three different houses, as I remember. The small company for which my dad was working transferred him there to Lemmon. This town was right on the mainline of the Milwaukee Road, which came through Lemmon. And to tell you a little about what a small town is like, I can remember on Sunday evenings at six o’clock people would go down and line their cars up to watch the big passenger train come through town. [laughter] It stopped, of course, to load water and a few passengers, I suppose. That was the big event.

But something about Lemmon, that I just wanted to comment on: there’s a book by a very good author, semi-religious, Kathleen Norris. She wrote this book called Dakota, which I bought and read. And you know, I knew who her grandfather was, because he was the local doctor; Totten was his name. You’ll see, she mentions that in the book. And she writes about going to Lemmon and assimilating into the area after living in New York. I guess she inherited the family farm, or something, and moved back there. Anyway, that’s Lemmon.

Swent:

It’s a wonderful book.

Fuerstenau:

Oh yes. And she has done others, as you know.

I have a little note here. My Grandmother Fuerstenau, who was German as I have said, always had a flower garden, out on the farm. This quite large flower garden was fenced in, and all summer long she planted flowers and tended this flower garden. That was just left over from her German heritage. In fact, later on, in his last forty years, my dad always had the back yard completely full of flowers. He probably acquired the taste of my grandmother.

Swent:

I think the flower garden on the farm was entirely the woman’s domain.

Fuerstenau:

Oh yes. It was fenced in so animals would not get in. I remember a gate on it, and so on, and all sorts of flowers that she tended, every day.

Swent:

Did she grow vegetables as well?

Fuerstenau:

Probably. Vegetables like carrots, peas and lettuce were tended by her. Rhubarb also. I think potatoes were farmed in a big way, but not necessarily for sale. Or maybe they did.

Swent:

So they grew their own food.

Fuerstenau:

Oh yes, sure. Chickens, eggs. Lots of chickens, turkeys, and even geese. I remember, even as a little kid, being chased by grandmother’s turkey gobblers. Gobblers are mean. And when you’re only three, four years old, they’re mean and dangerous animals.

Swent:

They had pigs and cows?

Fuerstenau:

Oh yes. Pigs, cattle, so on.

Swent:

Sheep?

Fuerstenau:

No sheep. In eastern South Dakota they didn’t raise sheep because that was farm land and not grassland like western South Dakota.

But you know, my mother talked about when Roosevelt became president they came in and took cattle, shot them and buried them. And I think you read about the idea that this would reduce the supply and raise the price. That obviously made a lot of farmers very unhappy, and I think that relatively poor people, like my relatives, became Republicans because of that. I think that issue was a major issue. My mother said they just came and said, “Okay, so many cows had to go. We’ll pay you, but we’ll take them.” And they took them out and shot them and buried them.

Swent:

That was terrible.

Fuerstenau:

I have no recollection of that, although I do remember my dad butchering a pig one day.

Swent:

What did your father do after he lost the farm?

Fuerstenau:

I think he worked for two yeas or so for a wholesale liquor distributing company. That’s what I think that was, but I don’t remember any more about that. But that job disappeared.

Swent:

Was that during Prohibition?

Fuerstenau:

Was it? No. ‘35, ‘36. My own thoughts are that North Dakota may have been dry, and that is why the company had an outlet there in Lemmon right there on the border of North Dakota. That’s my opinion, but I’ve never asked anybody about it.

Sometime in late 1936 that job disappeared. Then he taught woodworking, probably under one of those NRA [National Recovery Administration] programs for some time.

Now in 1936, it has to be that summer—you talked about grasshoppers. I can remember in that summer, the north side of the house would be coated with grasshoppers, a layer of grasshoppers three or four grasshoppers deep on the foundation, and probably working their way up the side of the house, staying out of the sun. I once commented on this some years ago to my mother, and she said the streets would be slippery driving because of squashed grasshoppers. That’s how thick they were! So here you had the droughts plus this terrible plague of grasshoppers. Did you see them down in the Black Hills?

Swent:

Well, not so much in the Hills. But driving across the state I certainly remember them. We couldn’t open the car windows because of the grasshoppers, and we nearly suffocated in the car. I remember once in Chamberlain when it was 112 degrees.

Fuerstenau:

An all-time record, almost.

Swent:

Yes, and we stopped in Chamberlain, and that’s what the thermometer was registering. It must have been 1936.

Fuerstenau:

Yes, yes. Another thing about Lemmon, we didn’t live near the railroad, maybe three or four blocks away. Actually, it was a nice house my parents had rented, right across from the school.

Often, my mother fed hobos—the guys that rode the rails. They would come by and she would have them perhaps do a little work or something. And we’re talking about fairly clean-looking guys that were probably in their twenties.

Swent:

A lot of them were farmers.

Fuerstenau:

And she said that she thought that somewhere down by the railroad tracks there was probably written, “If you want a meal go to such and such an address.” I still recall that quite often, she made this comment how they seemed to come to our house. And she was very kind.

Swent:

I remember that too. I remember my mother giving fried eggs, and bacon, and bread, and coffee—feeding men who came to the door. But they were farmers who had been burned out, who came looking for work. I think they came to everybody’s door, maybe. And some of them cried because they were so—they were desperate.

Fuerstenau:

Oh yes.

Swent:

It was a terrible time.

Fuerstenau:

I mean, just for everybody, farmer or working somewhere.

Swent:

You haven’t mentioned church.

Fuerstenau:

We were raised good old German Lutheran.

Swent:

There wasn’t much choice, was there?

Fuerstenau:

Well, let me tell you, my mother, who was Norwegian, had gone to a Norwegian Lutheran church, and it blows my mind that the German Lutherans looked down on the Norwegian Lutherans, and the German Lutherans—

Swent:

Luther was a German.

Fuerstenau:

Yes, I know. But there was this pecking order. I sensed it, and my mother told me that because she was Norwegian my grandmother considered that she wasn’t as good as the Germans.

I remember going to the country church when we lived on the farm when I was four or five years old. Then, either every Sunday, or every other Sunday, the sermons were in German. I can still remember some of the other old farmers coming to talk to my dad, and the first thing was, “Wie gehts.” Then even in Lemmon, maybe every other or every third church service would be in German. This would be 1935, ‘36. I think all the ministers went to a Lutheran seminary and of course had to learn German. And maybe an awful lot of them had already learned it as kids anyway.

Sunday church was always a steady thing. Of course, later I went through the catechism and confirmation that takes place.

Swent:

Did they do any farm work on Sunday?

Fuerstenau:

No, no, they never did. Other than during harvest time, of course, when you really must complete the harvest in case of rain. Sundays were a time for people to call on friends.

Swent:

You had to milk the cows.

Fuerstenau:

Oh yes. Cows had to be milked, chickens fed, eggs gathered on Sundays, but there was no plowing or anything else.

Swent:

What about the music in the church?

Fuerstenau:

In the country church, my Uncle Martin was the organist. He was a farmer. He was several years younger than my mother, but she had taught him in grade school that year, and she said that that was the brightest person she ever knew as a student.

Swent:

This is your father’s brother?

Fuerstenau:

Yes, younger brother. And he started college for a year, but was enticed with a farm to become a farmer. And now this very bright guy’s whole career was spent as a farmer. As I said, he was the church organist. And my dad and all my uncles were very good musicians. Another uncle, my dad said, was the best trombone player in the whole area. My dad was a very good violinist. If he hadn’t been a farmer he might have been a musician. As a little kid I remember him practicing every night, playing the violin or clarinet.

Then when we lived in Lemmon, I started taking piano lessons, which I did for five years. Not that I ever got that good.

Swent:

So music has always been a part of your life?

Fuerstenau:

Oh yes. That started with me during the last two years there in Lemmon.

Out of all the relatives, only my dad’s youngest brother, Adolph, graduated from college and he became a parochial school teacher in a Lutheran church in Wisconsin. He and his family visited us in Lemmon in the summer of ‘37, and I drove back with them to eastern South Dakota and spent the summer on the farms with relatives.

Summers with Cousins on Eastern South Dakota Farms

Fuerstenau:

That summer I first spent about three weeks with my Grandmother Fuerstenau, and at that time, an unmarried uncle that she lived with. And then, with my Uncle Elmer and family, who was now living on the farm that my parents had lost. Obviously they were renting it.

It’s funny, I can still recall seeing headlines of something that I knew nothing about at the time in the Watertown paper, “Amelia Earhart Lost,” in great big letters. And I can still see that headline. Of course, at the time, I didn’t know anything about her.

During that summer, I stayed with relatives at four different places, including my other grandmother who lived in Watertown. She came out to get me in her old Model-T [Ford]. Roads then, as you well know, were either just gravel or dirt. It had rained, and she decided to go down a steep hill alone in the car while two of us walked down. There was another lady with her. And the whole fields were just full of little frogs and little toads. Did you ever see a field like that?

Swent:

No.

Fuerstenau:

I remember the expression used to be, “It rained the toads.” Of course, the water brought them all up from under the dry soil—I mean they were just jumping all over. You never see that any more.

So I spent probably two or three weeks in Watertown with her, and after that some time at another aunt and uncle’s, which was my mother’s sister, Clara Roisum—farmers near the small town of Lake Norden, south of Watertown. At that time there were two girls, cousins of mine, one my age. These cousins made the newspapers in eastern South Dakota because they had tamed a steer that they could drive and ride, and they would be in parades with this steer. By that time it was the last part of the summer and that meant harvest time—and this uncle had one of these big old Avery tractors that you saw then, one that would go about one mile an hour, with huge wheels, and a canopy over the top—it ran the threshing machine. I still recall all that was involved in threshing at that time.

Swent:

Did helpers come?

Fuerstenau:

Oh yes. I’ll tell you later about threshing in general. But first I want to tell you about another problem. My aunt and uncle had gone to Watertown for the day, and the three of us were there at the farm, and a cow was in a little stream along the edge of the farm. It didn’t flow much; it was a remnant stream flowing between two small lakes. And then all of a sudden the cow just died standing up in the water. It turns out that it was anthrax. Several cows died during the next day or two. Because anthrax is a disease that is dangerous to humans too, these cows all had to be pulled out and then taken out into a field and burned under piles of straw. That was a traumatic experience, because it came on that quickly. I don’t know how many cows they lost, but I assume it was two or three. And probably more around the region. When I returned home in the fall, I would have been in fourth grade.

By the way, one thing that cold country like Lemmon is very good for is ice skating in the winter time. They would flood half a city block around which the fire department had built a low dirt retaining wall. And so ice skating was always the main thing to do in winter, although it was very cold. Your toes could get a little—

Swent:

It would be awfully cold.

Fuerstenau:

You’re right about that. Anyway, obviously life was not good for my parents. So in the summer of 1938, my mother went down to Black Hills Teachers College in Spearfish and took classes to renew her teaching certificate, which will account for the next year.

Early that summer, my folks drove from Lemmon back to Watertown for a visit, and I remember that around Aberdeen the whole place was stripped by Mormon crickets. They were those great big Mormon crickets. You could see them everywhere. They would strip the whole countryside, around Aberdeen. They weren’t around Watertown.

Swent:

And they made the highway very slick too; I remember still.

Fuerstenau:

They must have. Those were big.

Swent:

I remember there were warning signs.

Fuerstenau:

Is that right?

Swent:

At some point I remember seeing signs along the road that warned of crickets. You had to drive carefully, they were such a menace.

Fuerstenau:

I believe it. Knowing about ordinary grasshoppers, and these were much bigger.

Swent:

Terrible.

Fuerstenau:

Yes, yes. It was around Aberdeen where the Mormon crickets were very bad, which is where our current Senate leader, Tom Daschle, comes from. The soil in that part of South Dakota has a high concentration of arsenic—and that comes from the poison used in the thirties to control the crickets and grasshoppers.

That summer I spent on the farm of my uncle Martin with two cousins, Norman of my age and his younger brother, Gilbert. I would have been nine at that time, so the summer consisted of half play, half work. Lots of play. I remember catching pigeons, and putting them in a big caged crate where I would fatten them with grain. Those were happy pigeons, being fed grain, but at the end of the summer I guess we ate them all.

Work involved cultivating corn with horses and plowing with a tractor. I actually got fairly good at cultivating and plowing in a straight row. Starting about then, there was a program of planting trees under a program of shelter belts to stop the wind from blowing dust. Every farm had maybe a 100 or 200-feet-wide band of trees of different kinds that went along the length of fields. Around the farm houses of eastern South Dakota, the homesteaders had planted trees on the north and west side of the farm buildings. So around my grandmother’s farm house there already was a grove of trees. But the shelter belts were planted on a much larger scale, probably in 1938, ‘37. It was a major program that really changed the area. Today, eastern South Dakota has a lot of deer, foxes, and animals like that because of the shelter belts. There were no deer, no foxes, in those earlier days. The trees allow that. But shelter belts do stop the wind from blowing dirt.

So anyway, that summer involved lots of work and lots of play and also maybe three weeks of summer Bible school, that the church always had each summer.

But then came fall, which was the harvest time. The same thing applied for the two years that I was there: namely a group of farmers who were all inter-related, either Fuerstenaus or married to Fuerstenaus harvested together. Two farmers that were cousins of my dad had adjacent farms across the road from each other, and these were fairly prosperous farmers. One named Hubert and the other Jake. They never married and they both died at about 95. My mother said they had all their marbles at 95, which is wonderful. This was the Jake Fuerstenau who was head of the school board that would not rehire my mother in her first teaching job.

Jake owned a huge steam engine tractor, the kind that you have seen in old pictures. Hubert owned the threshing machine, a big threshing machine. And so the threshing involved a coal-fired steam engine. In those days, the grain was first cut with a binder after which, as a kid, we picked up the bundles and stacked them into shocks. The crops then were wheat, and barley, and oats, and maybe flax. Those were the main ones. Millet, I guess, another one. The dust storms were gone by then.

Anyway, that fall in order to run the steam tractor, a trainload of coal had to come in on the railroad, and the coal then was hauled to each farm to run the steam engine. Getting the coal on time was a problem. The general procedure was that two days of threshing would be done at each farm. There may have been six or eight at most. As I said, all of the farmers were related to each other, in a three- or four-square mile area. The group would thresh at one farm for two days, then they would go to the next farm for two days, and then to the next one, two days, so that each one could get some money by taking grain down to the grain elevator. I remember my cousin and I would take those first loads of grain in a horse-driven grain wagon to the elevator at the railroad station. It was about five miles or so that we had to go. We also loaded grain bundles with pitch forks into a hay wagon and hauled them to the threshing machine. The time for threshing was always a huge occasion. All the wives did the cooking and there were, of course, really two dinners a day—a big dinner at mid-day and another big dinner in the evening for the threshing crew. And after they had made the two-day circuit, they would start over again and then thresh out everything for each farmer. So they made two circuits through the system.

Swent:

And prayed that it wouldn’t rain.

Fuerstenau:

Also so that it wouldn’t hail. The following year—I was there one more summer—was essentially all work. Summer of ‘39, so I was now ten. And that summer, at first it rained just as harvest was to begin, and as you know for harvest that’s bad. But the second problem was that the load of coal for the steam tractor didn’t come in from the railroad. And that held everything up for I don’t know how many days, several days. Then it rained for a bit. And of course, for the farmers in that area, hail storms can wipe them out completely. There was real angst that they had at that time of year. By the way, threshing machines were used until the mid 1940s, when harvesting was done by combines, which cut, thresh and clean the grain in one operation. Today when you drive through eastern South Dakota, every little while in a field right along the highway you see a relic threshing machine, like a monument to times past.

Swent:

Did your mother stay there to help too?

Fuerstenau:

She wasn’t there at all. No, the wives of the farmers took care of all the meals, et cetera. They would have been my aunts.

Swent:

I thought maybe your mother had to go back and help too.

Fuerstenau:

No, no, she had no relationship with that, nor my dad.

I was there for three summers, and I consider that a good part of my growing up.

Swent:

Wonderful experience.

Fuerstenau:

As a young kid you have a lot of responsibility if you are on a farm. The last summer involved plowing a bit with a tractor, stuff like that. I was only ten then. And I’ll tell you, it’s not easy to drive a tractor in a straight line while you’re plowing. Sounds easy, but—. [laughs]

Swent:

And there are an awful lot of hazards too.

Fuerstenau:

You know, there really are.

Swent:

They wouldn’t let a child around there now.

Fuerstenau:

When you stop and think about a tractor with no cover over the wheels! Then that was a typical farm tractor. All of that machinery. When you cut corn and so on. At times people did fall in, and get chopped to bits. People lost arms, and stuff like that. Nobody I knew, but one read of them.

Swent:

Very dangerous.

Fuerstenau:

Oh yes. Farm machinery was dangerous. And I suppose it’s like all machinery that you use daily—you forget the dangers. For miners that’s often—they talk about you have to be careful about that which is routine, you don’t make the short cut and so on.

Those last years I was involved in milking, and maybe going out and getting the cows and bringing them in. Some of them were milked by milking machines and some were—I remember my uncle had an old—one of these one-lung motors, you know, you start and it goes, “chug, chug.” I would hear that and then I would wake up to hearing this chugging. It was supplying the vacuum line for the milking machine in the barn. You had to do a lot of the milking. Some cows wouldn’t like the milking machine. You had to learn how to milk, which—once you learn it’s easy, but it takes a while. [laughs]

A Year at Slick Creek Country School

Fuerstenau:

In 1938, I told you my mother went to summer school at Black Hills Teachers College to renew her teaching credential and got a job teaching in a country school called Slick Creek School. [pronounces it “Slick Crick” and laughs, spells] And this was near Lodge Pole, South Dakota, south of Hettinger, North Dakota, which is about twenty-five or thirty miles west of Lemmon. And this was a country school, right on the Grand River. My dad came out on weekends for a while. Then they rented an old abandoned farm about two miles away where we lived in the farm house for that year.

Swent:

Did you go to the Slick Creek School?

Fuerstenau:

Oh yes. This was all eight grades, and I was then in the fifth grade. My mother was the teacher.

You know the Grand River, shortly before it flows into the Missouri, is where Sitting Bull lived. South of that there’s the Cheyenne River, the White River, right? I don’t remember all of them. About four or five rivers cross western South Dakota. The most northern one is the Grand River. It wasn’t very grand. It was, you know, ten to thirty, fifty feet wide. That type of thing.

Swent:

And four inches deep.

Fuerstenau:

Right, most of the time. And anyway, we were there that year, and I remember the dirt and Russian thistles, and I always told my son how the ant hills near the Grand River were basically Indian beads—little tiny blue, and red, and white beads. Indians, of course, had camped along the river, and so the ant hills had a large percentage of Indian beads which the ants were using as sand grains. Everybody always had collections of arrowheads. One spring day walking to school over the dirt where nothing was growing, I remember finding a great big Indian spearhead that I had for many years. Somewhere I lost it. But it was just lying on the top of the dirt in this field. We were there that entire year.

Swent:

Were there Indian children in school with you?

Fuerstenau:

No, none, not at all.

In the spring and the fall one could fish in the river for bullheads, the standard fish. But I do remember the ice breaking up in the spring. And of course, we ice-skated on the river in the winter, which was about our only entertainment. In the spring, the ice broke up, and it’s amazing to see masses of ice chunks break up and crash. That took place in a single day. I think they let school out so people could go watch it. It would make big ice dams that would dam up the water for a while, but then it would break loose and the water would rush on.

Farmers, along that river irrigated by pumping from the river, so there were only a few farms there. I remember the farmer who was head of the school board, his name was Lingel, a German. One evening we were visiting Lingel, and he wanted to listen to Hitler talk on a shortwave radio. That was a speech Hitler was giving in Germany. But I didn’t know any German then.

Swent:

Do you have any recollection of what his attitude was towards this?

Fuerstenau:

Not really. But anyway, they were all second-generation Germans. Of course, this was just at the time when all Europe was concerned with what Hitler wanted to do.

Swent:

How was that, having your mother as the school teacher?

Fuerstenau:

Probably made me work. [chuckles]

Swent:

I’m sure.

Fuerstenau:

My mother was a superb teacher. I remember almost nothing about the school except for taking the state performance tests. It was a one-room country school with a dozen or fifteen kids, at most.

Swent:

Some of whom were your siblings.

Fuerstenau:

Right. Maybe all of them. It must have been. Maurie could have been in the first grade, but maybe not.

Four Years in Mobridge, SD, Right on the Missouri River

Fuerstenau:

When school was out that summer I went back again to the farm. This would be ‘39. Then my parents got what amounted to a dual job with a Lutheran academy in Mobridge, South Dakota, which is on the Missouri, west of Aberdeen. My mother took care of the dormitory, and my dad the grounds and buildings [supervisor] for this. I think this was probably a good school, which was closed a few years ago. But farmers from 100, 200 miles around who wanted to send their kids to this high school, could do so.

Swent:

And you went to the same school?

Fuerstenau:

For one year. This was a high school. I was now in sixth grade when we moved to Mobridge. So I did sixth, seventh, and eighth grades in the Mobridge schools and then the ninth grade at this Lutheran academy.

Swent:

But some of them were boarding students.

Fuerstenau:

Most of them. Most of them were. There might have been three or four that were local, or five or six. But it was a boarding school, and I think it served a very good purpose. A very solid education.

The summer of 1942, which I often think back on, I can hardly believe how much work I did for so little. There were three different truck gardeners right along the river—one big one owned by Steve Denoff right near where the highway bridge crossed the Missouri. He wanted to hire people to pull weeds. Some grade school friends suggested that we go down to see if we could get a job. So we went down to the river, were hired, and got paid ten cents a row, and I really pulled a lot of rows. He had a large truck farm where he grew all sorts of vegetables, melons, and possibly some fruit, and everyday he made a trip to town delivering fresh vegetables to the stores.

Anyway, he hired me and another high school kid after the few days of weed pulling, to continue working. He paid me eight cents an hour, and the high school kid twelve-and-a-half cents an hour. The high school kid, after about three weeks, finally quit. But I didn’t, and you know, I worked all summer, six days a week, and it was from seven in the morning until six at night. I got up and left at six and either hitched a ride with a road grader, because there were still a lot of gravel roads—or with two Indians in an old car going to work somewhere. Either one or the other picked me up in the morning down along the road. I usually walked back. It was a mile and a half, maybe, cutting across the right-angle highway. By the way, we drove to South Dakota in 1975 and saw that all three ancient flood planes of the Missouri where the truck farms had been were under water because of the construction of the Oahe Dam near Pierre. By then, a lake about two or three miles wide came right up to the city limits of Mobridge.

Sometimes I stop to think about that dedication—five bucks a week. That experience may have entered into the dedication towards work that I’ve had. And of course, through all the years, I have told my own kids about my pulling weeds for eight cents an hour, especially when they were little. They heard “eight cents an hour” a lot.

But you know, the other day I looked up something because I wanted to know just how bad pay in general was then. I had just read an interesting book called Freedom from Fear: The American People in Depression and War, 1925-1945 by David M. Kennedy, published 1999, Oxford Press—big volume. It got the Pulitzer Prize two years ago. And I had read this book and I remember—

Swent:

He teaches at Stanford, doesn’t he?

Fuerstenau:

He’s at Stanford, yes. In history there.

Anyway, I remembered seeing something about what pay was at one point, so the other day I looked it up. In 1940, the average industrial wage in the U.S. was seventy-four cents an hour. And he said retail clerks got thirty-five to fifty cents an hour. So an adult working for thirty-five cents an hour in a store was not that much better than the eight cents an hour I got as a kid, pulling weeds.

Swent:

You weren’t being especially persecuted to get the eight cents an hour either; that was probably the going wage.

Fuerstenau:

Must have been, when you were paying high school kids around that.

Swent:

It was probably a fair wage.

Fuerstenau:

I don’t call it child labor or anything, but I ended up doing a lot of things: driving a tractor, pulling wagons, cultivating, and things like that. Then in the fall at the time of the final harvest, he paid fifty cents for two hours’ work after school. That’s when you really have to get everything in before the first frost. In South Dakota frosts can come pretty early. Swent:

And that’s the end.

Fuerstenau:

So that fall I started high school at the Lutheran academy.

Swent:

Were your teachers there mostly men?

Fuerstenau:

They were all men and they all were ordained ministers. Not that they were preaching. Well, they preached once in a while. They were addressed as professors. In fact, one of the ministers had married my parents in 1925. It was his first wedding back in a country church in eastern South Dakota near Hazel.

But Mobridge, again, was sort of like Lemmon in winter in that ice-skating was your main activity. There were several excellent ice-skating rinks.

Swent:

What kind of skates did you have?

Fuerstenau:

I think in Lemmon they were strap-on ones, but they were hockey skates by the time I was living in Mobridge. I was in sixth, seventh, eighth grade. Not that I ever did much hunting, but sometimes in winter I would go out rabbit hunting because you could get fifteen cents or something like that for a white jack rabbit.

Swent:

Who bought them?

Fuerstenau:

Somebody locally. I remember often coming back so cold. We would get what was called “chilblains.” Oh boy, did that hurt! And it takes a long time to get over it, an hour or two, it seemed.

Swent:

On your face?

Fuerstenau:

No, usually toes. Toes and maybe fingers. We would have earmuffs and stuff. Once your feet start getting cold, you can’t do much about it, right?

Swent:

No. What sort of clothes did you wear to the Lutheran school? A uniform?

Fuerstenau:

No uniform at all.

Actually, there was by definition a course in religion, but I must have taken at least five other courses. This was more than one would take in a high school. That came to my advantage later on. I took a course in German, and Latin, and I suppose algebra, and whatever you took in English, and history, and so on—obviously, solid, good courses.

Then that summer, or late spring, my dad had some kind of job offer in Provo, Utah. And he got as far as Rapid City where a second cousin of his, named Adolph Stoltz, owned a Coast-to-Coast store. Stoltz talked my dad into staying there and working for him. So that’s how we moved to Rapid City, summer of ‘43.

Swent:

At this academy—this is the middle of the war—were there current events classes and was there any particular sensitivity about what was going on in Germany?

Fuerstenau:

Well, I do know that German services stopped in church. By the way, my mother said that in World War I, in South Dakota, a lot of German Lutheran congregations found their churches painted yellow, and stuff like that. Then eastern South Dakota was a quarter or more German, and many were first generation immigrants. That was World War I, but in World War II there was none of that really.

Swent:

Of course, these people were all a couple of generations removed.

Fuerstenau:

But it’s interesting about Charley Lingel—that was his first name—wanting to listen to Hitler’s speech on the shortwave radio. But that was in 1938 just before the war really started. So what his interests and leanings were, I—

Swent:

I wonder if any of these people were still maintaining any contact with relatives back in Germany?

Fuerstenau:

I knew none of that.

Swent:

They really cut themselves off once they came here, didn’t they? That was it.

Fuerstenau:

Yes, yes. One of my mother’s sisters had some interaction with cousins in Norway, for example, even up to modern times. That’s the only interaction I ever heard. I’ve never bothered to look up anybody when I have been in Europe.

Swent:

They didn’t have telephones, and e-mail, and all those things.

Fuerstenau:

Right, true. I did get a letter once asking for some reprints; this was twenty-five years ago when we were living in Germany—I’ll be into that later. This professor wrote from what was then East Berlin, saying that he had a close friend, a Lieutenant Fuerstenau, who was killed in the war, wondering if that was a relative of mine. Who knows? I’m sure glad that my grandparents had left Germany.

My dad said the whole family had moved to this country. But obviously there might be secondary relatives that we all have that we don’t—.

Swent:

But they just completely cut loose from them.

Fuerstenau:

I think the one thing that really stopped was anybody speaking German much. When we lived in Lemmon, that church really had a lot of old Germans—lots of first-generation people who spoke German. I remember one man named Wulff who said that he had homesteaded in 1909, about twenty miles west of Lemmon, and that when he got there, the whole countryside was grass three or four feet tall. Grass like that is gone. By the way, in 1878-79 eastern Dakota territory was open for homesteading, and at Wulff’s time thirty years later land available for homesteads had moved on to western South Dakota.

I want to come back to the Slick Creek School. I always told my son Steve about the ant hills with the Indian beads. The only time we were back in that area was 1975, when he must have been about twelve. He wanted to find the ant hills with the Indian beads, so we went looking. That whole area is now the National Grassland, and that summer everything was covered with green grass. So there were no Indian beads to be found. [laughs] No arrow heads, or Indian beads, or anything to be found, because of the grass.

But anyway, my parents became good friends of a family named Storm—and they were farmers—from church in Lemmon. They lived across the North Dakota state line—just north of Thunder Hawk, South Dakota. Wilhelm Storm had homesteaded there about 1906, and ended up with several sections of land. He was obviously quite astute.

You asked earlier about electricity. Well, when they first put electricity on their farm it was put in the barn. [laughter] The house didn’t come for two to three years later, my mother said. A real old German.

Swent:

First things first.

Fuerstenau:

First things first.

A Summer Herding Sheep in North Dakota

Fuerstenau:

Anyway, their son Walter had the farm next door, and I got a post card asking if would I come and herd sheep. So I did that for the summer of 1943. Walter Storm then had about 2,000 sheep. The sheep were in an area probably two square miles, or so, of rolling prairie land. Every night the sheep were put in a pen that was about a mile or two away from the farm house. I would head out by seven in the morning and put the sheep in at six, and then ride my horse back to the farm.

I did that seven days a week. And only a couple, three times in that whole summer did I have any time off, probably on a Saturday or a Sunday. I was now fourteen. And I think that was not good to be working seven days a week—. Once in a while, a young guy who was spending the summer at the father’s farm came out, and he and I went swimming in the nearby Cedar River, a couple of times. But, basically I did that every single day and—

Swent:

All alone.

Fuerstenau:

All alone. I had a worthless dog. It’s funny. The dog was so useless that I just never took it with me, only a horse. At first I just left the saddle tight on the horse all day. Walter Storm rather forcefully told me to loosen the saddle because the belt strap started to cut through the hide of the horse. I didn’t know that. And he said, “You should know better than that.” I didn’t know better than that; I had never been told. Anyway, after that I then always loosened the saddle straps.

About noon the sheep, as you might know, all huddle together, until about three o’clock in the afternoon. You’ll see big groups of them, a hundred, all together with their heads down. Finally I asked, “Why do they do that?” Well, apparently it keeps the bugs and the flies off their nose. Having all their heads down inside that mass of sheep in the hot summer must not have been too pleasant.

That summer I remember reading airplane magazines. It was in the war. I would buy those airplane magazines, and read about fighters, and bombers, and whatnot.

A lot of times I would wake up and the sheep were gone. I know one time I went up one draw, down this draw, because it was all hilly, water cut, called draws. I finally found the horse. I could see the sheep way off, probably two miles away. Then I had to go and drive them back.

Another time was worse than that, because when I woke up—Little Bo Peep asleep under the haystack—I could see the sheep way off in another corner where there was a field of oats, and they were out in that oat field. You can imagine getting about 2,000 sheep out of a field of oats without a dog. I just had to ride back and forth on this horse. I got them out, finally. I imagine this was late in the summer, because the oats were already getting brown. So the farmer, whoever he was, must have been shocked at harvest time to see one end of the field trampled. That must have been manna from heaven for the sheep to get fresh oats like that.

So I did that the entire summer. I amused myself with things. By experiment I found a little rabbit can swim only three times across a small stream. [laughter]

Swent:

A little scientific research.

Fuerstenau:

Right. It was terrible.

Swent:

Then, at the end of the summer, I had to go to Rapid City. So how do you get from Lemmon to Rapid City when there was no train or bus—did you ever know about star mail routes?

Fuerstenau:

You could make reservations with the star mailman. His route went from Lemmon to Faith, something like that.

Swent:

Buffalo, I remember.

Fuerstenau:

Well, then somewhere we changed to another mail man and went to Newell where I caught a bus down to Rapid.

Now that you mentioned Buffalo, I had made another note here. A few years ago, my friend Frank Aplan sent me a book. The book is entitled Sheep, and then in small letters it’s called Life on the South Dakota Range. This book is written by Archer [B.] Gilfillan. It’s republished by the Minnesota Historical Press—first published in 1929, and a new edition was published in ‘93. When Frank sent the book, he said, “This is no joke.” And I read the book. Gilfillan had graduated from Penn, University of Pennsylvania, and had worked, like I did, on farms in the summer and had gone out to Buffalo, South Dakota, and herded sheep a little bit for somebody. Then he returned to the East somewhere, I think St. Paul, Minnesota or maybe Chicago, and entered a seminary to study for the ministry. Just the day before graduation, he decided not to graduate and went back out to Buffalo. He had an inheritance of a few thousand dollars and bought a farm that he lost. Then he spent the next sixteen years herding sheep, after which he wrote this book. Of course he lived in one of those sheep wagons that you’ve seen pictures of. I didn’t. But he wrote beautifully about how the sheep reacted. I had observed many of these very same things about sheep.

Swent:

I remember that name.

Fuerstenau:

He died in Deadwood in ‘55. But he worked, after he left the sheep, in the ‘30s. He lived in Igloo, south of the Black Hills, and wrote once in a while for the newspapers. In the book, Sheep, he describes the lambing time. During my summer of sheepherding, two sheep had lambs. They were there for a few days and then unfortunately the coyotes got them. After that Walter Storm told me to find the ewes and milk them. So for a few days, I tried to recognize them; maybe they were bleating because they were not doing too well, and I would milk them for a bit.

Swent:

Did they use the milk?

Fuerstenau:

No, it was just to get rid of it because they lost their lambs to the coyotes. You would see coyotes around once in a while.

Swent:

So you went in the morning and let them out of the pen, and then they just went—?

Fuerstenau:

In an area that was probably two square miles or more that was available for grazing.

Swent:

And the oat field was not fenced?

Fuerstenau:

There was a fence around the oat field, but some section of it must have been down. I was the herder that was supposed to look after the sheep and keep them in the grass area. But when the sheep were spending about three hours clustered, I usually took a nap.

Swent:

Were you supposed to keep coyotes away?

Fuerstenau:

I didn’t have a gun or anything. But by the way, when I first got there, the first day, they were shearing the sheep.

Swent:

By hand?

Fuerstenau:

Some of them were like a big hedge clipper and they also had heavy duty electric shears. They went fast, and of course they nipped the sheep a lot too.

Swent:

Local people, or did they bring in helpers?

Fuerstenau:

Oh, Walter Storm, and probably a couple of other helpers. The wool was put into bags that were as tall as the door, let’s say. And I remember I was the person inside of the bag stomping the wool. I wasn’t very happy about that. I thought, “What if there are ticks here?” But at least nothing happened. But that was my very first day on the job.

By the way, I got paid thirty-five dollars a month that summer. And of course that involved room and board also. But still, that’s just a little over a dollar a day, wasn’t it? I was getting eighty cents a day pulling weeds, so I’m assuming I didn’t get taken that badly.

Swent:

You took a lunch with you?

Fuerstenau:

Oh yes, sure. Of course, my worst experience was when the seven bucks got loose. They were several miles away, and when they found the sheep, I couldn’t do anything. Finally, in about the middle of the afternoon, I put all the sheep in the pen with the bucks—they must have been in heaven—and went home to get Walter Storm, wherever he was, to come back and get those damn bucks out of there.

Swent:

They were not normally with the sheep?

Fuerstenau:

They came from several miles away. I don’t know where they were kept. He may have had an awful lot of young lambs that winter; I have no idea. [laughter] That situation I just couldn’t handle. Still, as a young kid, trying to solve problems like that was, again, a good part of one’s developmental background. I was 14 years old that summer.

Swent:

I’m thinking, there must have been days when it rained?

Fuerstenau:

Only towards the late summer, when some days got grey. I remember two days then when there was a drizzle rain. I did crawl under a haystack, and slept under the haystack out in a field. I hollowed out a spot and took my nap under the haystack. I probably had a rain jacket on. I don’t remember now what the sheep did. But, as I recall, there were no thunderstorms. None that whole summer.

By the way, Wilhelm Storm, the father of Walter Storm, owned about 2000 acres, with much of it in wheat. I know that in one of those years he got something like 50,000 bushels of wheat. By then, harvesting in northwestern South Dakota was done by large crews traveling with several combines. They started in Kansas and worked their way north. They would come through and they would handle on a so-much-per-bushel basis, do all of the harvesting. So farmers such as the Storms didn’t do any of their own harvesting. I have no recollection of that in the eastern part of the states where the farms were smaller. Harvesting was done by tin threshing the way I mentioned, but later eastern farmers then bought their own combines. But in the western part, it was done by these crews because acreage of farms was so much bigger.

Swent:

That was a timing problem too, to get the combines.

Fuerstenau:

Oh yes. But I have no idea how that was worked out. I imagine it was managed by contract with the same group each year.

Moving to Rapid City, South Dakota, and High School

Fuerstenau:

Well, it was ‘43 when we moved to Rapid where I entered the tenth grade in Rapid City High School. My dad had been offered a job in Ogden, Utah, and stopped in Rapid City on his way to visit his second or third cousin, Adolph Stoltz. He was offered a job there and decided to stay in Rapid City instead of going on to Utah. Rapid City was and is the second largest city in South Dakota. Of course, the major thing of Rapid City was the air base. It was the final B-17 training base before they went to England. I recall seeing those massive flights congregate over Rapid City—where they were obviously practicing congregating into a great airwave. The air base dominated Rapid City at that time.

Swent:

It was the Ellsworth Base, wasn’t it?

Fuerstenau:

It wasn’t called that then.

Swent:

What was it called?

Fuerstenau:

I think it was simply called Rapid City [Army] Air Base. You see, Colonel [Richard E.] Ellsworth was the base commander, probably in the early fifties, when he was killed in a crash of a B-52 bomber that he was piloting over Greenland. That’s when they named it Ellsworth Base.

You know about traffic jams. In ‘43, ‘44, ‘45 there was a steady stream of cars going to and from the air base at seven o’clock in the morning and five o’clock in the evening. It completely dominated Rapid City then.

Swent:

Big change.

Fuerstenau:

Yes. Well, you know, the weather was very good for flying because western South Dakota has so many days of sunshine.

[Interruption]

Fuerstenau:

Before we were talking about Rapid City High School. I think public schools were very good in those days.

Early on, after starting at Rapid City High School, I saw some kind of ad about wanting a high school student to work for a couple, three hours after school in a grocery store. It was a semi-sized grocery store called the Spic ‘n Span, and it was owned by somebody named John [T.] Vucurevich. I went down and talked to him, and he hired me. He owned this store, and with his wife, maybe three or four other people worked there. And Vucurevich, who was then about thirty-four, got drafted into the army sometime during that year, ‘43, ‘44. I remember seeing him wearing a private’s uniform.

Anyway, I worked at the Spic ‘n Span on Saturdays, and after school, all the way into the fall of ‘45 or a little later.

John Vucurevich is interesting to talk about because he came from Lead, and he and his wife had, maybe in Spearfish, a little restaurant or café before coming to Rapid City. John Vucurevich had only gone through the ninth or tenth grade in Lead. I think he was born in Yugoslavia, and came over as an infant with his parents.

Swent:

I think his parents had a grocery store in Lead.

Fuerstenau:

Anyway, he—and I have seen him in very recent years—he is a very well educated man. When he came back out of the army, he bought a state bank in Hill City. Then, he transferred that state bank to Rapid City. Eventually, he owned many banks in South Dakota, Iowa, and Wyoming, all through the state bank system. He was in the state legislature for a few years, and now is a wealthy individual who has set up foundations in Rapid City, and in Vermillion at the University of South Dakota. Amazing success story, and a very nice man. I’ve visited with him several times through the years when I’ve been in Rapid City. He’s still alive, still sharp, eighty-five or more. [Note added by Douglas Fuerstenau: John Vucurevich died at age 92 in 2005.]

Swent:

I think his mother was killed in that flood.

Fuerstenau:

She was. His mother was killed in the 1972 Rapid City flood, along with nearly three hundred others.

Swent:

Were there that many?

Fuerstenau:

Yes. But his mother was one. Those were all very nice houses, down along Little Rapid Creek, as you know. And obviously it overflowed, and she must have been in one of them. She had to be quite senior then.

Swent:

Yes. I may be mistaken. Maybe his father worked in the mine; I don’t know.

Fuerstenau:

Must have. I vaguely remember reading somewhere that he did.

Swent:

What we called “Slavonians,” in Lead—I think they were really Dalmatians, from Dalmatia—several of them did have grocery stores.

Fuerstenau:

Is Dalmatia Croatian?

Swent:

Some of them were Serbs and some of them were Croatian, I think.

Fuerstenau:

But John is such a self-educated person with only a ninth or tenth grade education in Lead.

Swent:

They were a very fine family. They’ve all done well. His brother, Alexander, was the one I knew better. The younger one.

Fuerstenau:

After Vucurevich was drafted, the store was managed by Bill Miller and I continued to work there. That really eliminated a lot of extracurricular activities that I would have had in high school.

Swent:

But you were probably learning other things.

Fuerstenau:

Certainly. I still recall prices then. For example: a pint of ice cream was fifteen cents; a loaf of white bread—from Swander’s Bakery—cost fourteen cents, and whole wheat bread was eleven cents a loaf. I also learned a fair amount about meat. The butcher at the Spic ‘n Span was Bob Henderson, a native Scotsman who must have been in his early sixties then. He used to take a lot of the credit for my success. A lot of people are always taking credit for my success. [laughter] Anyway, he not only was the butcher, but also he was a real fisherman who could always get trout in Rapid Creek. And I more than once went fishing with him and he would watch what the fish were biting and that would become our bait. When he was taking a break, or wasn’t at the store, I would be the butcher. I’ll tell you, it’s not easy to slice a slice of ham on a bone with a saw. And those days, sliced ham was the most expensive meat you could get. It’s hard to understand why.

Swent:

Well, meat was rationed.

Fuerstenau:

Oh yes, completely. Everybody had the rationing books, as you remember. Gasoline especially. My brothers and my dad were all ardent hunters, but I never was. And I think that because there was no gasoline when I was in high school, I never went out hunting and never developed the kind of interest in hunting that my brother Maurie has.

[Interview 2: July 25, 2001 in Berkeley, CA]

Swent:

When we stopped on Monday, you had just gotten to Rapid City. You recalled some things about your grandmother’s garden that you thought were worth mentioning.

Fuerstenau:

You had asked me about my grandmother’s garden. I now remember, my Grandmother Karterud lived on the edge of Watertown. She had a huge garden. They grew all their vegetables, I think probably for the winter. My Grandmother Fuerstenau, I now recall, always grew a lot of nice fresh lettuce, carrots, peas, beans, and so forth, and I had completely forgotten about the main dessert which was rhubarb. Rhubarb pie and rhubarb sauce. And to this day, a great radio program is Prairie Home Companion, where Garrison Keillor is always talking about rhubarb pie. That’s the only fruit-like thing that will grow in eastern South Dakota, and probably western Minnesota. No apples, but crab apples and choke cherries.

Swent:

And your grandmother probably made pie almost every day, didn’t she?

Fuerstenau:

Well, it was part of life.

Swent:

You moved to Rapid City in 1943, and it was the middle of the war.

Fuerstenau:

Directly in the middle of the war. Rapid City, at that point, was one of the main air bases in this country for training B-17 bombers.

Swent:

What about Pearl Harbor, when that happened?

Fuerstenau:

Then we lived in Mobridge, and I can still remember that late Sunday afternoon, maybe at five or six o’clock in the evening, hearing on the radio about Pearl Harbor. Of course everybody was very concerned. Not like I understand how people were out here in California on the coast. But I remember that the next day—I was in eighth grade—there was a general assembly held in the school so that we could listen on the radio to Roosevelt’s speech and declaration of war. I can still hear his voice.

Swent:

The South Dakota National Guard had already been activated at that time. Did you know anybody in the Guard?

Fuerstenau:

No, I really didn’t. I was a little too young, fortunately.

Swent:

Right. I thought you might have had neighbors or uncles.

Fuerstenau:

Too small a town.

Swent:

Because they were activated, actually, before Pearl Harbor.

Fuerstenau: